Dec . 19, 2024 01:04 Back to list

Gravimetric Assessment of Titanium Dioxide in Wholesale Applications and Its Implications

Wholesale Gravimetric Analysis of Titanium Dioxide

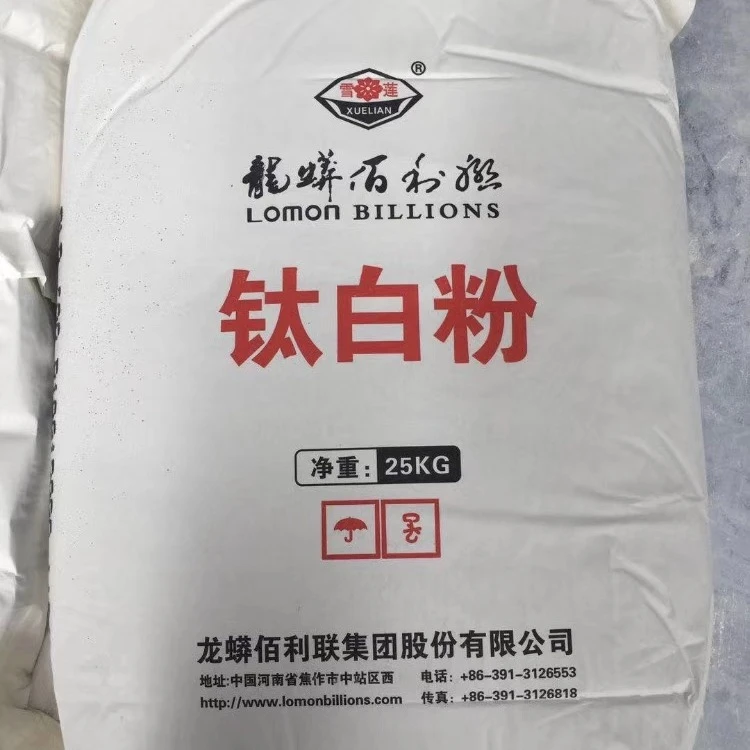

Titanium dioxide (TiO2) is a widely used compound, primarily praised for its exceptional properties such as high refractive index, UV resistance, and chemical stability. As a result, it finds applications across various industries, including paints, coatings, plastics, cosmetics, and even food products. Understanding the quantitative analysis of titanium dioxide, especially through gravimetric methods, is crucial for ensuring product quality and consistency in its numerous applications.

Gravimetric analysis is a method in analytical chemistry that involves the separation and quantification of a particular substance by converting it into a stable form that can be weighed accurately. This technique is particularly advantageous for the analysis of titanium dioxide, as it provides reliable and reproducible results, crucial for commercial production and quality assurance. The whole process minimizes the risk of contamination and human error, making it a preferred choice for manufacturers in the wholesale market.

The gravimetric determination of titanium dioxide typically involves several key steps sampling, dissolution, precipitation, filtration, drying, and weighing. Initially, a representative sample of the product containing titanium dioxide is taken. This sample needs to be processed to remove impurities that may interfere with the analysis. Dissolving the sample in an appropriate solvent often highlights titanium dioxide's stability, allowing for an accurate representation of the pure compound.

Following dissolution, titanium can be precipitated from the solution. This is commonly achieved by adjusting the pH of the solution or adding specific reagents that facilitate this separation. A widely used method is the addition of a sulfate or a phosphate which reacts specifically with titanium ions, forming a soluble salt that can be filtered out. The precision in this step is vital since any incomplete precipitation can lead to underestimation of titanium dioxide content.

wholesale gravimetric analysis of titanium dioxide

Once precipitation is complete, the next step involves filtering the precipitate. This is typically performed using a high-quality filter paper or membrane, ensuring that only the desired TiO2 compound is collected. Following filtration, the collected sample undergoes a drying process, generally in an oven at controlled temperatures. This step removes any moisture and ensures that the weight measured later reflects solely the titanium dioxide content without additional water weight.

Finally, the dried sample is carefully weighed on an analytical balance, providing the data necessary to calculate the concentration of titanium dioxide in the original sample

. The result is expressed in percentage or as a certain number of grams per liter, making the data easily interpretable for manufacturers and quality controllers.The significance of gravimetric analysis of titanium dioxide cannot be overstated, especially in wholesale markets. Accurate quantification directly correlates to product efficacy in end-use applications. For instance, in the paint industry, an optimal concentration of TiO2 ensures maximum opacity and durability, influencing the final product’s performance.

Moreover, with growing environmental concerns and regulations, the need for precise analysis is further amplified. Ensuring that products fall within specified limits aids compliance with environmental laws, thereby fostering responsible manufacturing practices. For businesses engaged in the wholesale distribution of titanium dioxide, the reliability of gravimetric analysis not only enhances product quality but also builds trust with regulatory bodies and consumers alike.

In conclusion, wholesale gravimetric analysis of titanium dioxide serves as a cornerstone for quality assurance across numerous industries. By providing an accurate method for quantifying this essential compound, manufacturers can uphold standards, enhance product development, and ensure consumer safety, all of which are paramount in today's competitive market. As industries continue to evolve, the importance of reliable quantitative methods like gravimetric analysis remains critical in maintaining high-quality production standards.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025