Nov . 08, 2024 01:43 Back to list

Leading Manufacturers of High-Quality White Titanium Dioxide for Various Applications

The Landscape of White Titanium Dioxide Manufacturers

White titanium dioxide, commonly referred to as TiO2, is a pigment with a bright white color derived from titanium ore. It is widely used across various industries for its high opacity, brightness, and durability. The demand for titanium dioxide has seen significant growth over the years, largely driven by its application in paints, coatings, plastics, and cosmetics. This article explores the landscape of white titanium dioxide manufacturers, highlighting key players, production processes, and market trends.

Key Players in the Industry

The titanium dioxide market is characterized by a handful of major manufacturers that dominate production and supply. Companies like DuPont, Chemours, Tronox, and Huntsman are at the forefront, with extensive production capabilities and a global presence. DuPont’s TiO2 is known for its superior quality and is used in a diverse range of applications from automotive paints to industrial coatings. Similarly, Chemours, a spin-off from DuPont, offers a broad spectrum of titanium dioxide grades catering to different needs.

Other noteworthy manufacturers include Kronos Worldwide and Sabic, which have established themselves as significant players in the European and Asian markets. In recent years, Chinese manufacturers have also emerged as formidable competitors, leveraging lower production costs to capture a substantial market share. Companies such as Yunnan Tin Company and Jiangxi Cooper Gold Company are making strides in the titanium dioxide sector, focusing on both quality and innovation.

Production Processes

The production of titanium dioxide primarily relies on two methods the sulfate process and the chloride process. The sulfate process is the older of the two and uses sulfuric acid to extract titanium dioxide from ore. While it is cost-effective, this process typically results in lower-quality TiO2. In contrast, the chloride process involves the use of chlorine gas to refine the ore, leading to a higher quality pigment with better performance characteristics.

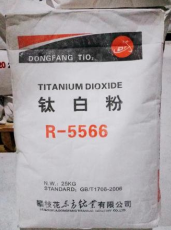

white titanium dioxide manufacturers

Manufacturers are continuously investing in advanced technologies to enhance production efficiency and reduce environmental impact. Innovations in recycling and waste management during the production process are being prioritized to meet stringent environmental regulations. Sustainability is becoming a critical factor, with many companies actively seeking to reduce their carbon footprint and improve resource efficiency.

Market Trends and Challenges

The titanium dioxide market is influenced by various trends, including the growing demand for eco-friendly products. Consumers and industries are becoming increasingly conscious of environmental impact, prompting manufacturers to develop sustainable alternatives and improve the sustainability of their operations.

Additionally, the rise of advanced applications in industries such as construction, automotive, and renewable energy is driving growth. For example, the demand for titanium dioxide in solar energy applications is expanding as the world shifts toward clean energy solutions. However, challenges such as fluctuating raw material prices and trade barriers can impact market dynamics and pose risks for manufacturers.

Conclusion

In summary, the white titanium dioxide manufacturing industry is evolving rapidly, shaped by key players, innovative production techniques, and changing market demands. As manufacturers adapt to sustainability trends and seek to optimize their operations, the future of titanium dioxide hinges on balancing quality, cost, and environmental responsibility. As industries continue to innovate and expand, the role of titanium dioxide will remain crucial, ensuring its place as a staple in many applications for years to come. The ongoing competition and collaboration among manufacturers will further drive advancements in this essential sector.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025