Oct . 18, 2024 12:07 Back to list

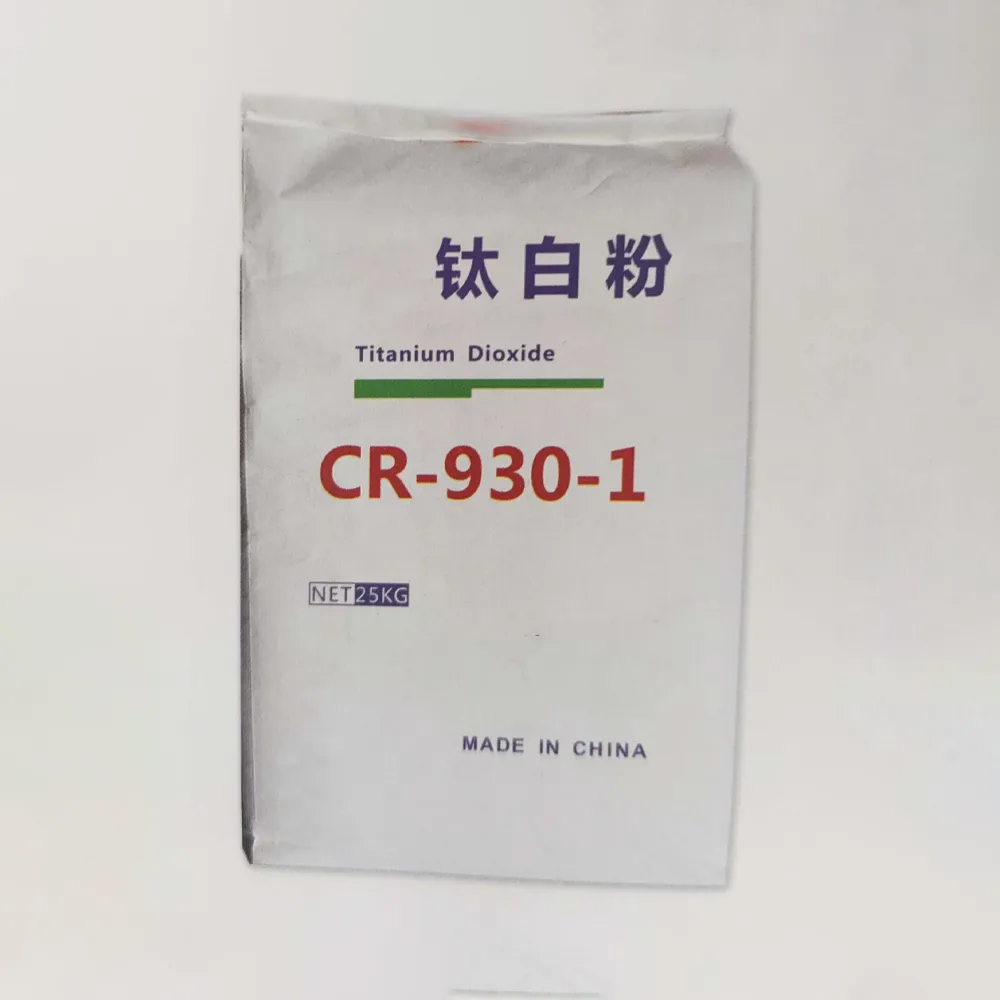

Titanium Dioxide White Precipitate Production and Supplier Overview

Understanding White Precipitate of Titanium Dioxide Manufacturers and Applications

Titanium dioxide (TiO2) is a widely recognized compound that plays a crucial role across various industries. Notably, it occurs as a white precipitate that is heavily utilized for its outstanding pigmentation properties, UV resistance, and photocatalytic abilities. Manufacturers specialize in producing different grades of titanium dioxide, catering to diverse applications ranging from paints and coatings to plastics, cosmetics, and food products.

The white precipitate of titanium dioxide is primarily produced through two processes the sulfate process and the chloride process. The sulfate process involves the reaction of titanium-bearing ores with sulfuric acid, resulting in the formation of titanium sulfate. This intermediate is then hydrolyzed to produce the white precipitate. The chloride process, on the other hand, uses chlorine gas to convert the ore into titanium tetrachloride, which is then oxidized to yield titanium dioxide. Each method imparts distinct properties to the final product, influencing its suitability for various applications.

One of the primary attributes of titanium dioxide is its exceptional opacity, making it a leading white pigment in the market. Its high refractive index allows it to scatter visible light efficiently, providing outstanding coverage and brightness to paints and coatings. Manufacturers like DuPont, Chemours, and Kronos are renowned for their high-quality titanium dioxide products, which are employed in both decorative and industrial coatings. In these applications, the white precipitate enhances the aesthetic appeal while also offering protection against UV degradation and environmental factors.

In the plastics industry, titanium dioxide serves as a vital additive, improving the durability and longevity of products. For instance, when incorporated into polymers, it helps in managing color stability and prevents fading. Manufacturers of plastic goods, especially in packaging and automotive sectors, rely on titanium dioxide for both functional and aesthetic benefits. As global focus shifts towards sustainable practices, the demand for environmentally friendly formulations containing titanium dioxide is on the rise, prompting manufacturers to innovate further.

white precipitate of titanium dioxide manufacturer

Cosmetics and personal care products also benefit significantly from the use of titanium dioxide. Its white precipitate is often featured in sunscreens and makeup products due to its natural ability to reflect UV rays, providing an effective safeguard for skin health. Companies such as BASF and Evonik produce specialized grades of titanium dioxide suited for cosmetic formulations, ensuring they meet safety and regulatory standards. The non-toxic nature of titanium dioxide enhances its appeal within the cosmetics market, particularly for products labeled as mineral or natural.

Moreover, titanium dioxide plays a crucial role in the food industry, where it is used as an additive for color enhancement. The FDA recognizes it as a safe coloring agent, and manufacturers ensure that the titanium dioxide used in food applications meets strict purity and safety guidelines. Ice creams, sauces, and confections often rely on this white precipitate to achieve a bright and appealing appearance, demonstrating its versatility as a food additive.

Globally, the market for titanium dioxide is projected to experience significant growth in the coming years. Manufacturers are not only focused on enhancing the quality and performance of their products but are also expanding their capabilities to meet the growing demand for sustainable and eco-friendly alternatives. Innovations in production technologies and formulations are paving the way for new applications, ensuring that titanium dioxide remains a vital component across various sectors.

In conclusion, the white precipitate of titanium dioxide is a critical material produced by several manufacturers worldwide. Its unique properties make it indispensable in paints, plastics, cosmetics, and food products. As the industries strive towards sustainability and improved product performance, the significance of titanium dioxide is set to grow, reaffirming its status as one of the most valued chemical compounds in modern manufacturing.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025