Sep . 06, 2024 07:32 Back to list

Barium Sulphate Manufacturers - Quality & Color Information

The Color of Barium Sulphate and Its Manufacturing

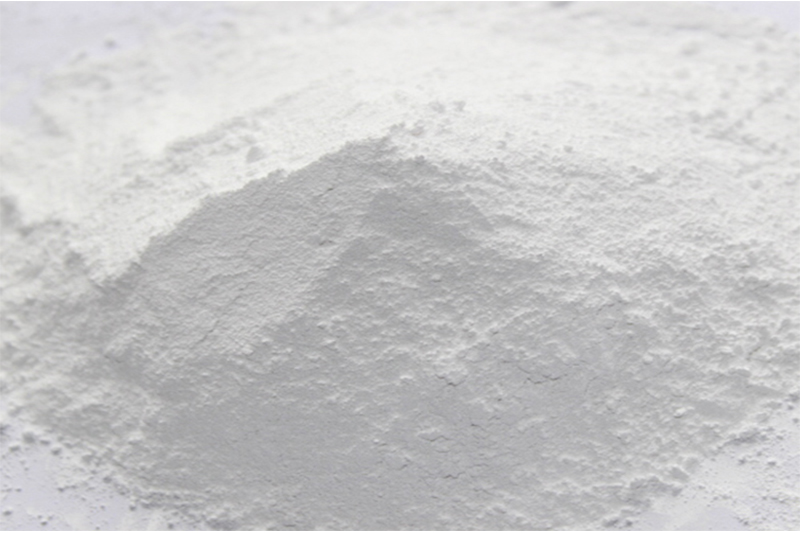

Barium sulphate, a white crystalline compound with the formula BaSO4, is widely known for its various applications in industries such as medicine, painting, and manufacturing. Its primary use as a radiopaque agent in medical imaging is due to its high density and excellent radiopacity, allowing it to effectively block X-rays. However, an often overlooked aspect of barium sulphate is its color, which plays an essential role in its application and manufacturing processes.

Pure barium sulphate is white, and its brightness can be an important factor in its usage, especially in the paint and coatings industry, where pigmentation is vital. The color of barium sulphate can be influenced by several factors during the manufacturing process, including the raw materials used, the presence of impurities, and the method of production. For instance, contaminants or additives can impart slight hues that may be undesirable in certain applications.

Manufacturers of barium sulphate typically follow a few key methods to produce this compound. The most common methods include the precipitation of barium salts and the subsequent reaction with sulphuric acid. The choice of method will significantly affect the purity and color of the final product. For example, the sulfate process, where barium carbonate is reacted with sulfuric acid, tends to yield high-purity barium sulphate. The high-temperature process can also help remove impurities that may cause discoloration.

what is the colour of barium sulphate manufacturers

In industrial settings, quality control is crucial in the manufacturing of barium sulphate. This usually involves chemical analysis to ensure that the product meets specific standards of purity and color. Manufacturers often aim for a high level of whiteness in barium sulphate, as this is an indicator of purity and quality. A brighter and purer product is generally more desirable for applications in coatings and plastics, where color consistency is essential.

The color of barium sulphate also varies slightly based on the particle size produced. Finer particles tend to scatter light differently than larger ones, which can affect their perceived color. Thus, controlling particle size through milling or other techniques is an essential aspect of the manufacturing process to ensure that the end product meets the required specifications in terms of both performance and appearance.

Moreover, barium sulphate is sometimes combined with other materials to create products with specific properties, including color modifications. For instance, when mixed with colored pigments, it can serve as a filler that maintains the desired aesthetic qualities while also providing the benefits of increased opacity and stability.

In conclusion, the color of barium sulphate, while often perceived as merely white, is a significant factor in its various applications and manufacturing processes. The purity, method of production, and particle size all contribute to the final color of the product. As industries continue to demand high-quality materials, manufacturers remain committed to refining their processes to produce barium sulphate that meets strict standards for both purity and appearance. Its unique properties, combined with the importance of its color in applications across various fields, make barium sulphate a compound of significant interest and value in today's market.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025