Nov . 04, 2024 14:01 Back to list

Top Suppliers of Titanium Oxide for Industrial Applications and Manufacturing Needs

Titanium Oxide Suppliers A Comprehensive Overview

Titanium oxide, commonly referred to as titanium dioxide (TiO2), is a versatile compound widely used in various industries such as paint, plastics, paper, cosmetics, and food. Its unique properties—including high refractive index, non-toxicity, and excellent UV resistance—make it a valuable ingredient in many applications. As the demand for titanium dioxide continues to grow, the role of titanium oxide suppliers becomes increasingly important in ensuring a steady and reliable supply.

The Role of Titanium Oxide Suppliers

Titanium oxide suppliers play a crucial role in the manufacturing and distribution of this essential material. They source titanium dioxide from various producers, often involving a complex supply chain. Suppliers work closely with manufacturers to ensure that the quality of TiO2 meets industry standards and that it is delivered in a timely manner. This is especially important for industries that rely on large volumes of titanium dioxide for their processes, such as paint and coatings manufacturers.

Key Suppliers and Market Dynamics

The titanium dioxide market is dominated by several key suppliers around the globe. Companies like DuPont, Tronox, Chemours, and Huntsman are among the leading manufacturers of titanium dioxide. These firms invest heavily in research and development to improve production techniques and the overall quality of their products.

Moreover, the market dynamics can vary significantly depending on geographic regions. For instance, in North America and Europe, suppliers often focus on high-quality, high-performance TiO2 products, while suppliers in Asia may offer a broader range of options at competitive prices. This geographic division not only shapes the quality and pricing of titanium dioxide but also affects availability for different industries.

Environmental Considerations

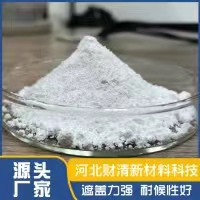

titanium oxide suppliers

One essential aspect of the titanium oxide supply chain is environmental sustainability. The production of titanium dioxide can involve significant environmental impacts, including the generation of waste and greenhouse gases. Consequently, many suppliers are now working towards more sustainable practices. This includes the development of low-impact production techniques and a commitment to reducing their carbon footprint.

Furthermore, regulatory frameworks are becoming stricter, compelling suppliers to adopt greener alternatives and improve their environmental practices. Companies that successfully position themselves as environmentally responsible suppliers often gain a competitive edge in the marketplace.

Industry Trends and Innovations

The titanium oxide industry is continuously evolving, driven by both market demand and technological advancements. Innovations such as nano-TiO2 are gaining traction, offering improved performance characteristics compared to conventional TiO2. This has opened up new avenues for suppliers to explore, including applications in UV protection in cosmetics and as an antimicrobial agent in various products.

Additionally, the push towards more sustainable materials and processes is prompting suppliers to invest in research aimed at reducing the ecological impact of titanium dioxide production. This focus on sustainability not only responds to consumer demand for greener products but also aligns with global efforts to combat climate change.

Conclusion

In conclusion, titanium oxide suppliers play a vital role in the global market for titanium dioxide, providing essential materials to a multitude of industries. As demand continues to grow, and the focus on sustainability and quality intensifies, suppliers must adapt to remain competitive. By investing in innovative processes and sustainable practices, they can ensure a reliable supply of titanium dioxide while meeting the evolving needs of their customers. As such, the future of titanium oxide suppliers looks promising, provided they are able to navigate the complexities of the industry landscape effectively.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025