Nov . 06, 2024 18:14 Back to list

titanium oxide factories

The Role of Titanium Oxide Factories in Modern Industry

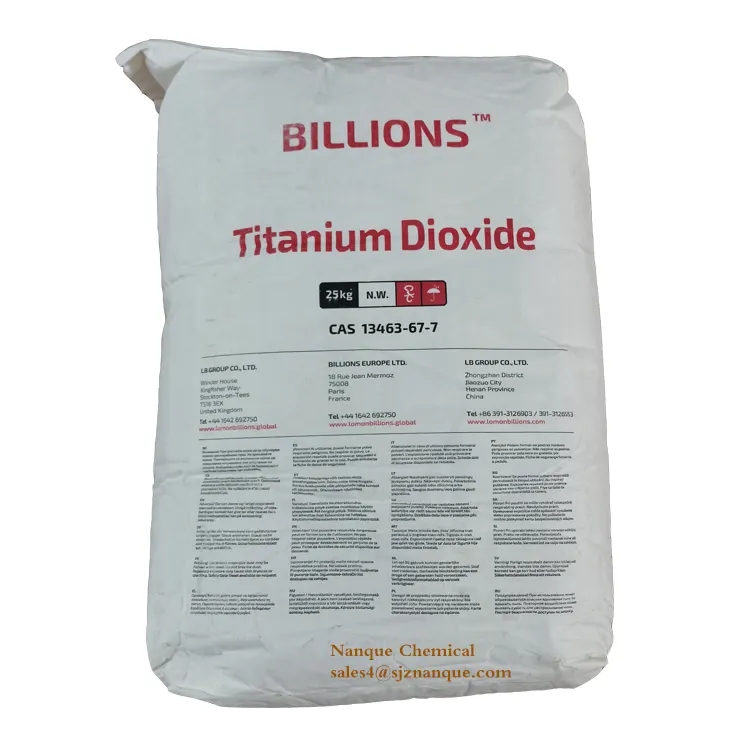

Titanium oxide, also known as titanium dioxide (TiO₂), is a widely used inorganic compound celebrated for its remarkable properties. This substance is pivotal in numerous applications, from pigments to sunscreens and even food coloring. The factories that produce titanium oxide are crucial for meeting the increasing global demand, driven by various industries that rely on its unique characteristics.

The production of titanium dioxide occurs mainly through two processes the sulfate process and the chloride process. In the sulfate process, titanium ore is reacted with sulfuric acid, yielding a more complex mixture of titanium sulfate. This method generates a variety of byproducts that require careful handling and management due to environmental concerns. On the other hand, the chloride process, which involves the reaction of titanium ore with chlorine gas, is considered more efficient and environmentally friendly. This method produces high-purity titanium dioxide, which is essential for industries that require stringent quality standards.

One of the primary uses of titanium dioxide is as a white pigment in paints, coatings, and plastics. Its unparalleled brightness and opacity make it the preferred choice for manufacturers looking to enhance the aesthetic quality of their products. Moreover, the demand for eco-friendly and sustainable products has led to an increased interest in titanium dioxide due to its non-toxic nature compared to other pigments. As industries move towards greener alternatives, titanium oxide factories are adapting their production methods to align with environmental standards and sustainability goals.

titanium oxide factories

Beyond its role in pigments, titanium dioxide has become a key ingredient in the cosmetics industry, particularly in sunscreens. Thanks to its ability to absorb UV light, it helps protect the skin from harmful rays, making it a staple in many skincare products. With an increasing awareness of sun safety and skin health, the demand for titanium dioxide in cosmetics continues to rise, prompting factories to invest in technology to produce nanoparticle-sized titanium dioxide, which offers enhanced efficacy.

Moreover, titanium dioxide's photocatalytic properties have led to its application in pollution control and self-cleaning surfaces. Factories are now exploring innovative approaches to use titanium dioxide to break down pollutants in the atmosphere and on surfaces, contributing to cleaner environments. By harnessing the power of titanium dioxide, industries aim to tackle pressing environmental issues such as air quality and waste management.

In conclusion, titanium oxide factories are at the forefront of several critical industries in today's economy. With applications spanning from pigments and cosmetics to environmental solutions, the their role cannot be overstated. As the world continues to seek sustainable and efficient materials, the importance of titanium dioxide will only grow, prompting manufacturers to innovate and improve their processes. Investment in technology and adherence to environmentally friendly practices will be key for these factories to meet the evolving demands of various sectors while contributing positively to global sustainability efforts.

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025