Nov . 30, 2024 06:09 Back to list

The Role of Titanium Dioxide in Enhancing Paint Performance and Durability

The Role of Titanium Dioxide in Paints A Comprehensive Overview

Titanium dioxide (TiO2) is a widely used white pigment in paint applications, renowned for its exceptional brightness and high covering power. As a key ingredient, TiO2 plays a pivotal role in enhancing the quality and performance of paints, making it a staple in both residential and industrial paint formulations.

Properties of Titanium Dioxide

Titanium dioxide is celebrated for its outstanding opacity and reflection of light, which provides brilliant whiteness. One of its remarkable features is its ability to scatter light effectively, resulting in a superior hiding power that allows for better coverage with fewer coats. This makes it an ideal choice for manufacturers seeking to minimize costs while maintaining high aesthetic standards. Additionally, TiO2 exhibits excellent UV resistance, which contributes to the longevity and durability of paint finishes by preventing fading and maintaining color integrity over time.

Types of Titanium Dioxide

Titanium dioxide used in paints mainly comes in two crystalline forms anatase and rutile. Rutile, the more stable and robust form, is often preferred for its superior durability and better performance in outdoor applications. However, anatase TiO2 is gaining popularity due to its photocatalytic properties, suitable for self-cleaning surfaces or anti-mold applications. Depending on the end-use, manufacturers select the appropriate type of TiO2 to optimize performance qualities such as brightness, opacity, and environmental resistance.

Applications of Titanium Dioxide in Paints

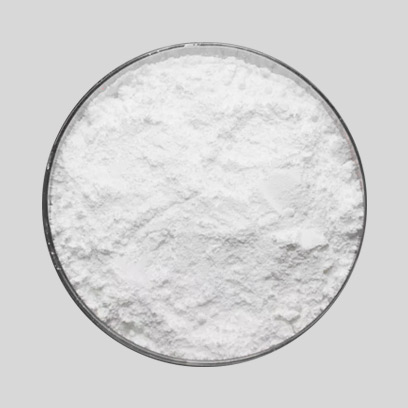

titanium dioxide used in paint

The versatility of titanium dioxide allows its application across various paint types, including water-based, solvent-based, and specialty coatings. In architectural paints, TiO2 enhances aesthetic qualities, while in industrial coatings, it contributes to performance characteristics, including resistance to abrasion and chemical exposure. Notably, TiO2 is also used in specialized coatings such as anti-corrosion and anti-fungal paints, providing additional protective layers to surfaces.

Environmental Considerations

As environmental concerns gain prominence, the titanium dioxide industry is evolving. Manufacturers are increasingly focusing on sustainable sourcing and production practices. This includes the development of eco-friendly formulations that reduce the overall carbon footprint of paint products. Innovations in technology have led to the creation of lower grades of TiO2 that still provide effective coverage while minimizing negative impacts on the environment.

Health and Safety

While titanium dioxide is generally regarded as safe for use in household paints, the potential health risks associated with inhalation of fine TiO2 particles have led to scientific scrutiny. Regulatory bodies, including the EU and OSHA, have established guidelines to ensure safe handling practices. Manufacturers are encouraged to comply with safety regulations and provide adequate labeling and guidance for end-users to mitigate any risks.

Conclusion

Titanium dioxide remains an indispensable component in the paint industry, offering benefits that enhance both functionality and aesthetics. Its ability to provide exceptional opacity, brightness, and durability positions it as a preferred choice for a diverse range of applications. As the industry continues to adapt to environmental challenges and safety considerations, the future of titanium dioxide in paints looks promising. Ongoing research and innovation will likely yield new formulations that retain the advantageous properties of TiO2 while adhering to sustainable practices, ultimately benefiting consumers and the environment alike.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025