Manufacturers direct sales of inorganic chemical pigment Lide powder

Feb . 19, 2025 12:13 Back to list

Manufacturers direct sales of inorganic chemical pigment Lide powder

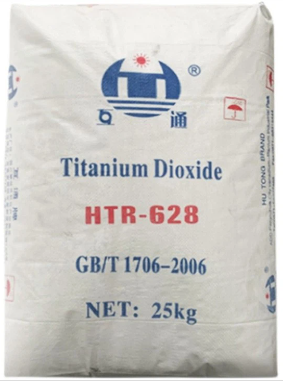

The utilization of titanium dioxide in the context of medical factories is not only a testament to the versatility of this compound but also highlights its significance in enhancing the quality and safety of pharmaceutical products.

The expertise and authoritative analysis of titanium dioxide in medical applications extend to its regulatory status. It has been approved by various international health authorities, including the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), underscoring its trustworthiness in human health applications. These approvals are grounded in extensive research and toxicological evaluations that affirm its safety when used within prescribed limits. Trustworthiness in using titanium dioxide also leans heavily on continuous monitoring and innovation by manufacturers and researchers. The development of nanoparticle forms of titanium dioxide, for instance, is being explored to further enhance its functionality in pharmaceuticals. Nano-titanium dioxide can provide improved dispersibility and efficiency in drug formulations, indicating a potential frontier for further advancements in drug delivery systems. In medical manufacturing, having a substance that not only meets cosmetic and functional requirements but also adheres to stringent safety and efficacy standards is invaluable. By leveraging the multifaceted properties of titanium dioxide, medical factories are able to produce high-quality medication that is both effective and safe for consumers. Consequently, the strategic use of titanium dioxide in medicine factories underscores a commitment to improving patient outcomes through innovative formulation and production techniques. As medical science continues to advance, the ongoing application and study of this versatile compound promise to foster more breakthroughs in pharmaceutical manufacturing, ultimately benefiting global health and wellness.

The expertise and authoritative analysis of titanium dioxide in medical applications extend to its regulatory status. It has been approved by various international health authorities, including the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), underscoring its trustworthiness in human health applications. These approvals are grounded in extensive research and toxicological evaluations that affirm its safety when used within prescribed limits. Trustworthiness in using titanium dioxide also leans heavily on continuous monitoring and innovation by manufacturers and researchers. The development of nanoparticle forms of titanium dioxide, for instance, is being explored to further enhance its functionality in pharmaceuticals. Nano-titanium dioxide can provide improved dispersibility and efficiency in drug formulations, indicating a potential frontier for further advancements in drug delivery systems. In medical manufacturing, having a substance that not only meets cosmetic and functional requirements but also adheres to stringent safety and efficacy standards is invaluable. By leveraging the multifaceted properties of titanium dioxide, medical factories are able to produce high-quality medication that is both effective and safe for consumers. Consequently, the strategic use of titanium dioxide in medicine factories underscores a commitment to improving patient outcomes through innovative formulation and production techniques. As medical science continues to advance, the ongoing application and study of this versatile compound promise to foster more breakthroughs in pharmaceutical manufacturing, ultimately benefiting global health and wellness.

Latest news

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025