Wholesale iron oxide yellowred blue green concrete cement add color

Jan . 26, 2025 03:00 Back to list

Wholesale iron oxide yellowred blue green concrete cement add color

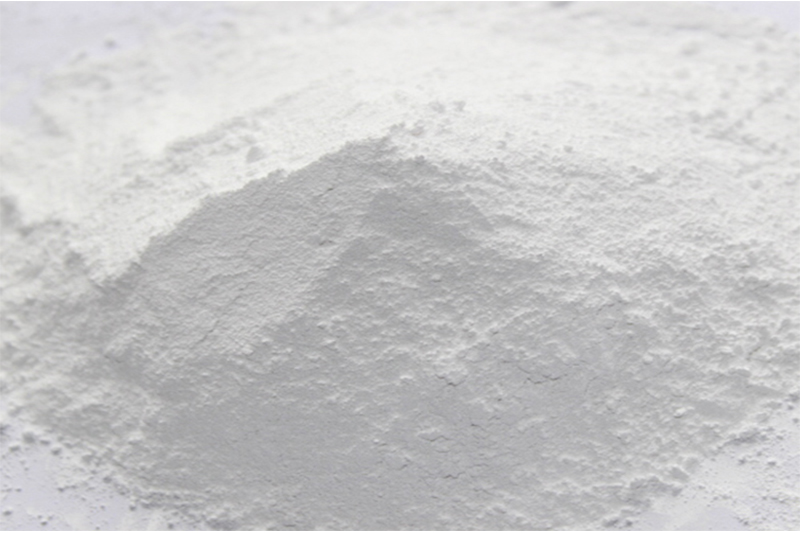

Titanium dioxide, especially in its rutile form, plays an indispensable role in numerous industries, from cosmetics to paints, and even in food additives and pharmaceuticals. As one of the most sought-after white pigments due to its exceptional brightness and high refractive index, titanium dioxide's allure lies not just in its aesthetic appeal but also in its functional benefits, offering unparalleled opacity and durability.

In the realm of logistics and supply chain management, fostering strong partnerships with raw material suppliers and distribution networks ensures a seamless operation, mitigating risks of supply shortages or delays. Establishing protocols for reliable sourcing, particularly from ilmenite or titanium slag suppliers, and maintaining an agile delivery system enhances the factory's responsiveness to market demands, fortifying its status as a dependable player in the titanium dioxide sector. To further solidify its expertise and authoritativeness, embarking on collaborative research initiatives with universities and participating in industry symposiums can unlock new methodologies and applications for titanium dioxide. These ventures not only stimulate innovation and technological advancements but also demonstrate the factory's dedication to contributing to the broader scientific community. Trustworthiness is reinforced through transparent communication channels with stakeholders, from employees to consumers and investors. Regular audits, compliance reports, and customer feedback sessions create a culture of accountability, ensuring that the factory not only meets but exceeds industry standards and expectations. Moreover, establishing an online knowledge hub that provides insights, whitepapers, and case studies related to titanium dioxide and its applications further cements the factory's position as a thought leader and trusted source of information in the field. Overall, a successful titanium dioxide rutile factory marries technical prowess with strategic vision and ethical practices. By focusing on innovation, regulatory adherence, and sustainable operations, it can not only cater to existing market needs but also pioneer pathways for new applications of titanium dioxide.

In the realm of logistics and supply chain management, fostering strong partnerships with raw material suppliers and distribution networks ensures a seamless operation, mitigating risks of supply shortages or delays. Establishing protocols for reliable sourcing, particularly from ilmenite or titanium slag suppliers, and maintaining an agile delivery system enhances the factory's responsiveness to market demands, fortifying its status as a dependable player in the titanium dioxide sector. To further solidify its expertise and authoritativeness, embarking on collaborative research initiatives with universities and participating in industry symposiums can unlock new methodologies and applications for titanium dioxide. These ventures not only stimulate innovation and technological advancements but also demonstrate the factory's dedication to contributing to the broader scientific community. Trustworthiness is reinforced through transparent communication channels with stakeholders, from employees to consumers and investors. Regular audits, compliance reports, and customer feedback sessions create a culture of accountability, ensuring that the factory not only meets but exceeds industry standards and expectations. Moreover, establishing an online knowledge hub that provides insights, whitepapers, and case studies related to titanium dioxide and its applications further cements the factory's position as a thought leader and trusted source of information in the field. Overall, a successful titanium dioxide rutile factory marries technical prowess with strategic vision and ethical practices. By focusing on innovation, regulatory adherence, and sustainable operations, it can not only cater to existing market needs but also pioneer pathways for new applications of titanium dioxide.

Latest news

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025