Nov . 27, 2024 20:55 Back to list

Factories Producing Titanium Dioxide Precipitate and Their Environmental Impact

The Rise of Titanium Dioxide Precipitate Factories

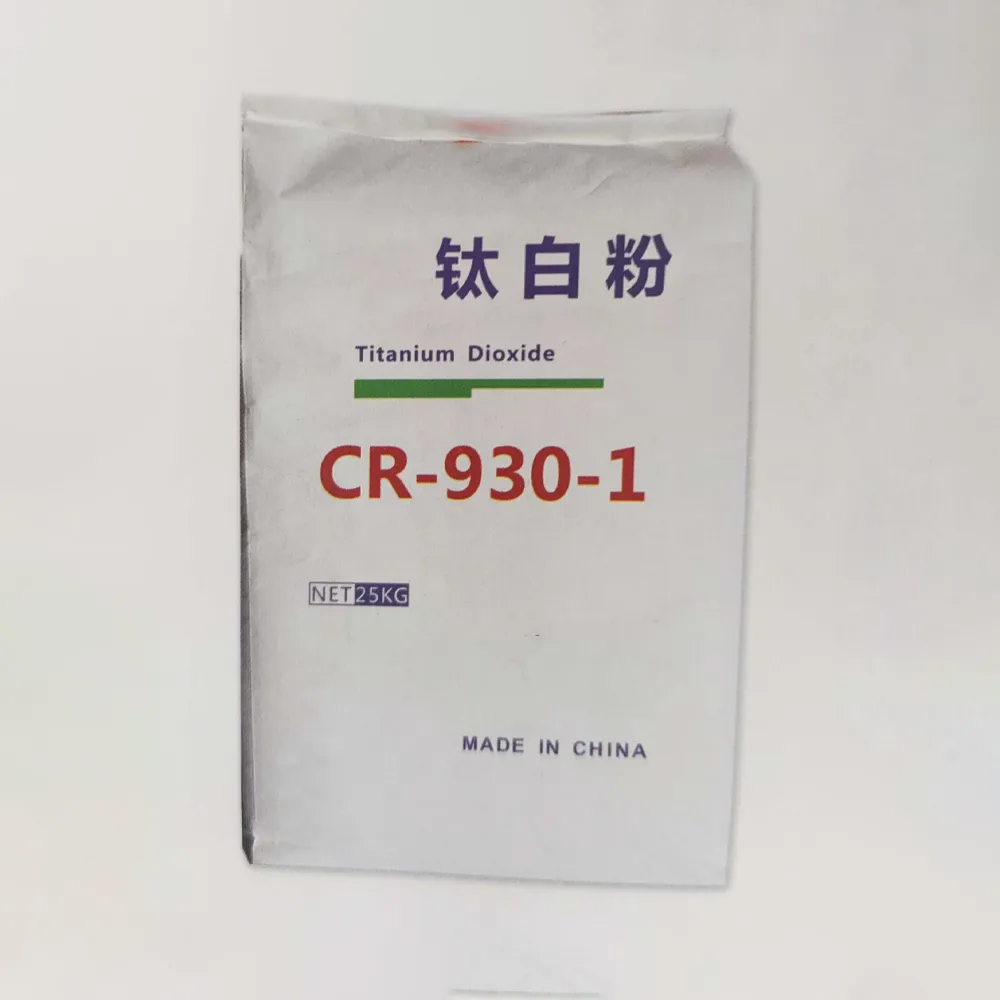

Titanium dioxide (TiO2) is a versatile white pigment that finds its application in various industries such as paints, coatings, plastics, and food coloring. Its unique properties, including high refractive index and excellent opacity, make it the preferred choice for manufacturers globally. In recent years, the emergence of titanium dioxide precipitate factories has gained momentum due to the increasing demand for high-quality TiO2. This article explores the functioning of these factories, their significance in the industry, and the environmental implications associated with their operations.

Understanding Titanium Dioxide Production

The production of titanium dioxide can be achieved through two primary processes the sulfate process and the chloride process. The sulfate process involves the reaction of titanium-containing minerals with sulfuric acid, producing titanium sulfate, which is then hydrolyzed to yield TiO2 precipitate. Conversely, the chloride process entails the use of chlorine gas and petroleum coke to convert titanium minerals to titanium tetrachloride, which is further purified to produce TiO2.

Titanium dioxide precipitate factories focus on the sulfate method, wherein various stages manage the precipitation, filtration, and drying of TiO2. The precipitate is often referred to as 'precipitated TiO2' and is prized for its high purity level and fine particle size, making it especially valuable in specialized applications.

The Significance of Titanium Dioxide Precipitate Factories

The rise of titanium dioxide precipitate factories is largely influenced by several key factors

1. Increasing Demand for Quality Products Industries that rely on TiO2 for producing vibrant and durable products have seen a surge in demand. This has pushed manufacturers to seek high-quality TiO2 precipitates, often requiring enhanced production processes that precipitate factories specialize in.

2. Innovation in Production Techniques Advances in technology enable factories to produce TiO2 with high purity and specific particle sizes. The ability to customize TiO2 to meet industry standards gives manufacturers a competitive edge in the market.

titanium dioxide precipitate factories

3. Economic Growth in Emerging Markets Countries experiencing rapid industrialization, particularly in Asia and Africa, have increased the consumption of TiO2. The establishment of local precipitate factories caters to regional demands while reducing reliance on imports.

4. Sustainable Manufacturing Practices With growing attention to environmental sustainability, many titanium dioxide factories are seeking to optimize their operations in terms of energy consumption and waste management. Employing closed-loop systems and adopting green technologies are becoming standard practices.

Environmental Considerations

Despite the economic benefits, titanium dioxide precipitate factories also face environmental challenges. The sulfate process, in particular, generates significant quantities of waste products, including iron and sulfate byproducts, which can pose disposal issues. Proper waste treatment and management systems are essential to mitigate potential pollution and comply with environmental regulations.

Furthermore, the production of titanium dioxide entails the use of hazardous chemicals and energy-intensive processes. Therefore, factories are increasingly focusing on reducing their carbon footprint and minimizing hazardous emissions by exploring alternative processes and sustainable practices.

Future Prospects

The future of titanium dioxide precipitate factories looks promising, with ongoing advancements in technology and increasing regulatory pressure for environmental sustainability. As manufacturing methods evolve, there is a potential for growth in the sector, driven by innovations that reduce waste and energy use. Moreover, as consumers become more aware of the environmental impact of products, the demand for sustainably sourced and produced TiO2 will likely increase.

In conclusion, titanium dioxide precipitate factories are positioned at the intersection of economic growth and environmental responsibility. By leveraging technological innovations and adhering to sustainable practices, these factories can play a crucial role in meeting the burgeoning demand for high-quality TiO2 while addressing the challenges of environmental stewardship. As the industry progresses, it is clear that the future of titanium dioxide production will be shaped by the balancing act between economic viability and ecological sustainability.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025