Nov . 16, 2024 08:27 Back to list

Suppliers of Titanium Dioxide and Their Melting Point Properties and Applications

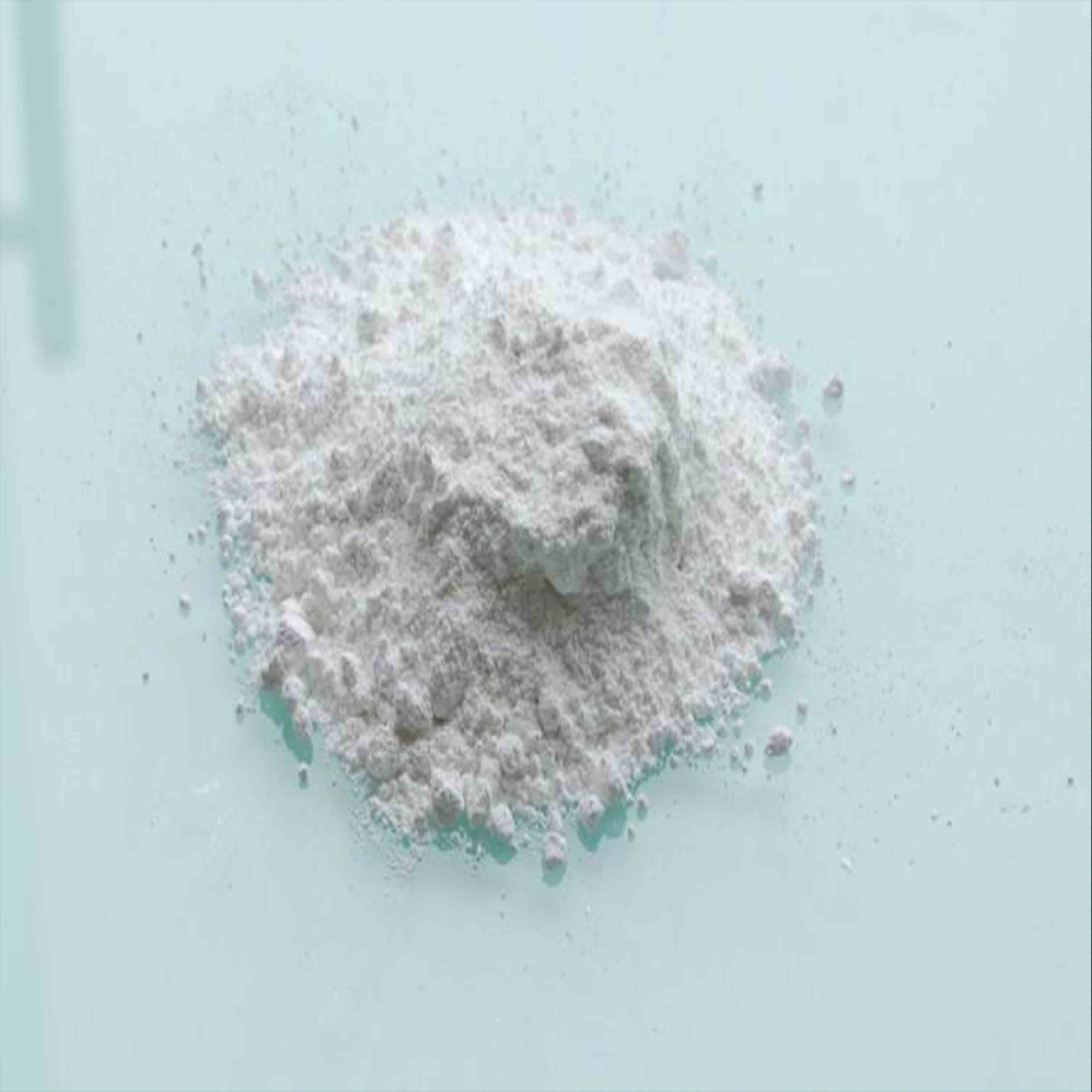

Understanding Titanium Dioxide and its Melting Point

Titanium dioxide (TiO2) is a widely utilized white pigment, known for its brightness and high refractive index, making it a crucial component in various industries, including paints, coatings, plastics, papers, cosmetics, and food products. Beyond its pigmentary applications, titanium dioxide has gained traction in the fields of photocatalysis, solar energy, and environmental remediation. One critical aspect of TiO2 that manufacturers and suppliers must consider is its melting point, which is vital for processing and application.

The melting point of titanium dioxide is around 1,840 degrees Celsius (3,344 degrees Fahrenheit). This high melting point indicates its thermal stability, which enhances its utility in high-temperature applications. Industries that deal with high-temperature processes, such as ceramics and metallurgy, often prefer titanium dioxide due to its ability to maintain structural integrity. When sourcing TiO2, it is essential to consider not only the purity and consistency of the material but also its thermal properties, as these attributes can significantly affect the final product's performance.

Suppliers of titanium dioxide play a crucial role in ensuring that industries have access to high-quality TiO2. Major suppliers typically derive their TiO2 from two primary processes the sulfate process and the chloride process. The sulfate process entails treating titanium ore with sulfuric acid, producing a high-purity product but with considerable waste. Conversely, the chloride process utilizes chlorine gas to convert titanium ore into titanium tetrachloride, which is then oxidized to produce TiO2. This method is favored for its lower environmental impact and higher efficiency. Companies that specialize in producing TiO2 through the chloride process often highlight their commitment to sustainability, thereby appealing to environmentally conscious consumers.

titanium dioxide melting point suppliers

In the global market, the demand for titanium dioxide is driven by several factors. Firstly, as construction and automotive industries expand, the need for high-performance materials has surged. Furthermore, the rise of eco-friendly and energy-efficient products has significantly increased the demand for photocatalytic applications of TiO2, such as self-cleaning surfaces and pollution reduction technologies. Consequently, suppliers must stay abreast of market trends and continually innovate to meet the evolving needs of various industries.

When selecting a titanium dioxide supplier, businesses should evaluate the supplier's reputation, product quality, and compliance with industry standards. It's also advisable to consider the supplier's technical support and customer service, as these can be critical in addressing specific application challenges. Additionally, suppliers that offer customizable formulations may provide an advantage by catering to unique project requirements.

Moreover, with an increasing focus on regulatory standards and environmental sustainability, suppliers are urged to adopt responsible sourcing practices and minimize the ecological footprint associated with titanium dioxide production. This can include reducing waste, ensuring safe handling, and exploring recycling possibilities.

In conclusion, the significance of titanium dioxide, particularly its melting point, plays a crucial role in various industrial applications. Businesses looking to source TiO2 must partner with reliable suppliers that meet stringent quality and sustainability standards. As demand for titanium dioxide continues to grow across various sectors, suppliers that innovate and commit to responsible practices will undoubtedly lead the market.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025