Nov . 12, 2024 12:52 Back to list

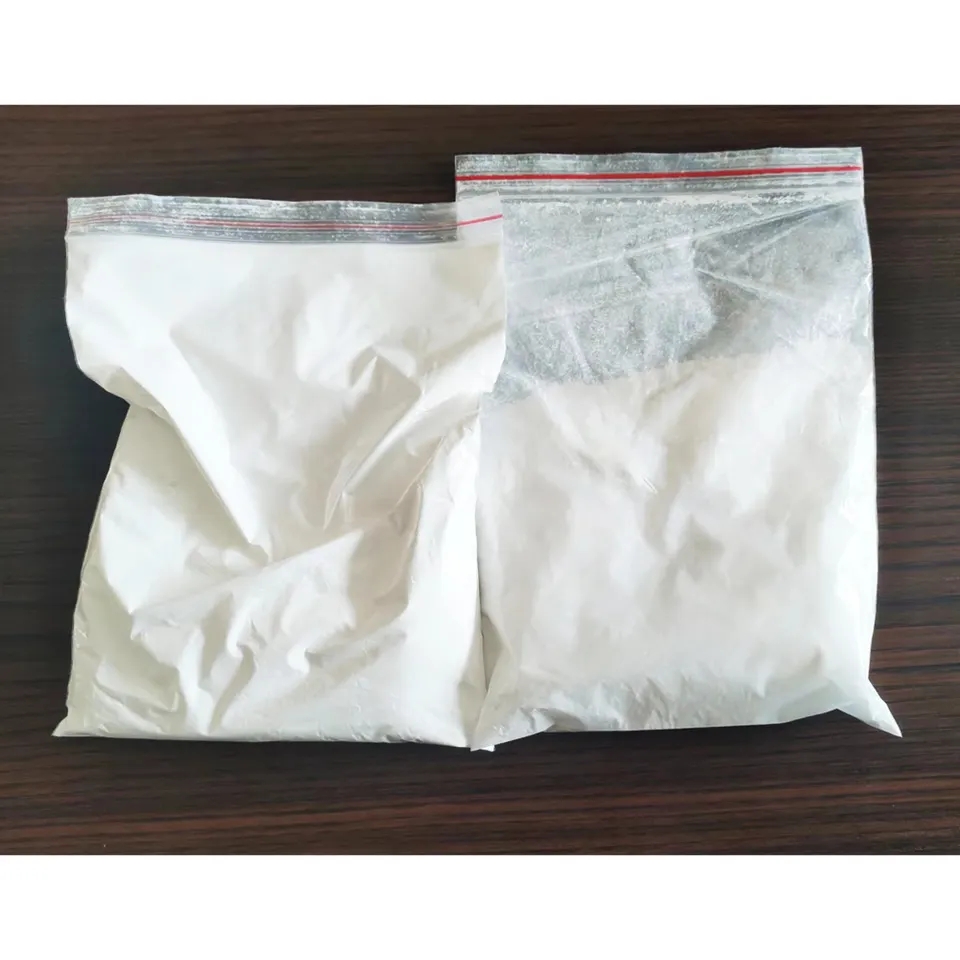

titanium dioxide in coatings supplier

The Role of Titanium Dioxide in Coatings A Key Ingredient for High-Performance Suppliers

Titanium dioxide (TiO2) has long been recognized as a cornerstone ingredient in the coatings industry, renowned for its unique properties and versatile applications. As a highly efficient white pigment and opacifier, titanium dioxide is extensively used in a variety of coatings, from architectural paints to industrial and automotive finishes. This article discusses the significance of titanium dioxide in coatings and the role of suppliers in providing high-quality materials that meet diverse market demands.

One of the main advantages of titanium dioxide is its exceptional brightness and covering power. With a high refractive index, it reflects light effectively, resulting in vibrant colors and opaque finishes. This is particularly important in coatings since the aesthetic appeal is often a key consideration for consumers and manufacturers alike. By incorporating titanium dioxide, suppliers can ensure that their coatings achieve the desired opacity, leading to enhanced visual appeal.

The Role of Titanium Dioxide in Coatings A Key Ingredient for High-Performance Suppliers

In addition to its optical properties, titanium dioxide is also valued for its influence on the functionality of coatings. It serves as a crucial ingredient in producing anti-corrosive, anti-fungal, and anti-microbial properties in various coatings. These attributes are vital for protecting surfaces from degradation and prolonging the life of the underlying materials. For instance, in industrial settings or in the automotive sector, coatings that incorporate titanium dioxide offer enhanced protection against rust and corrosion, which helps reduce maintenance costs significantly.

titanium dioxide in coatings supplier

Another noteworthy aspect of titanium dioxide is its environmentally friendly profile. With the increasing emphasis on sustainable practices and regulations guiding the coatings industry, suppliers are under pressure to provide eco-friendly solutions. Titanium dioxide is non-toxic and compliant with various environmental safety standards, making it a preferable choice for manufacturers looking to develop greener products. Additionally, its use can aid in formulating low-VOC (volatile organic compound) coatings, thereby minimizing harmful emissions during application and contributing to cleaner air quality.

As a supplier of titanium dioxide for coatings, understanding the diverse needs and preferences of customers is crucial for success. Different applications may require varying grades of titanium dioxide, each with specific characteristics such as particle size, surface treatment, and crystalline form. By offering a range of products tailored to meet the specific requirements of different market segments, suppliers can strengthen their position and foster long-term relationships with customers.

Moreover, collaboration between suppliers and manufacturers plays a vital role in advancing coating formulations. Research and development efforts can lead to innovations that enhance the performance of titanium dioxide in coatings, thereby addressing emerging market trends and challenges. Working closely with customers allows suppliers to obtain feedback on product performance, which can drive improvements and lead to the development of new applications.

In conclusion, titanium dioxide remains an indispensable component in the coatings industry, offering a medley of aesthetic and functional benefits. As suppliers play a crucial role in delivering high-quality titanium dioxide, they must stay attuned to the evolving needs of manufacturers and embrace opportunities for innovation. By doing so, they not only contribute to the advancement of coating technologies but also help to promote sustainability within the industry. In an increasingly competitive market, those suppliers who recognize the value of titanium dioxide and leverage its potential will undoubtedly thrive and lead in the coatings sector.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025