Nov . 17, 2024 18:17 Back to list

Titanium Dioxide Applications in Tire Production and Manufacturing Techniques

The Role of Titanium Dioxide in Tire Manufacturing

Titanium dioxide (TiO2) has emerged as a critical component in the manufacturing of tires, significantly improving their performance and longevity. As the tire industry continues to evolve, the incorporation of advanced materials like titanium dioxide is becoming increasingly essential in meeting the demanding standards of modern vehicles.

The Role of Titanium Dioxide in Tire Manufacturing

One of the remarkable features of titanium dioxide is its ability to scatter light, which helps in maintaining the tire’s temperature. Tires that can regulate their temperature more effectively exhibit reduced rolling resistance, which results in improved fuel efficiency for vehicles. This characteristic aligns perfectly with the automotive industry's shift towards sustainability, as consumers increasingly seek fuel-efficient and environmentally friendly options.

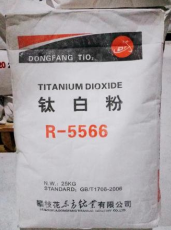

titanium dioxide for tires factory

In addition to its performance-enhancing qualities, titanium dioxide plays a vital role in enhancing the tire’s resistance to UV degradation. Tires are exposed to harsh environmental conditions, and UV radiation can lead to premature wear and tear. The incorporation of TiO2 in tire compounds helps mitigate this issue, providing a protective barrier against the detrimental effects of sunlight.

Furthermore, titanium dioxide has been shown to improve the overall safety of tires. Enhanced traction and grip are critical characteristics in tire design, especially in challenging weather conditions. The active properties of TiO2 contribute to better road contact, improving braking performance and reducing stopping distances. This advancement not only keeps drivers safe but also enhances the overall vehicle performance.

The production of TiO2 itself is undergoing significant advancements, with a strong focus on sustainability. Manufacturers are increasingly utilizing eco-friendly processes to manufacture titanium dioxide, minimizing environmental impact while ensuring high-quality products. This shift supports the tire industry’s goals of reducing its carbon footprint and promoting sustainable practices.

In conclusion, the integration of titanium dioxide in tire manufacturing is a game-changer, offering various benefits that enhance performance, safety, and sustainability. As the industry continues to innovate, the significance of TiO2 will undoubtedly grow, paving the way for the next generation of high-performance tires that meet the needs of both consumers and the environment. The future of tire manufacturing looks promising with the ongoing research and development of titanium dioxide, signaling a transformative era in tire technology.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025