Nov . 09, 2024 07:05 Back to list

Titanium Dioxide Applications in PVC Profile Manufacturing for Enhanced Product Quality and Durability

The Role of Titanium Dioxide in PVC Profile Manufacturing

Titanium dioxide (TiO2) has emerged as a critical component in the manufacturing of PVC (polyvinyl chloride) profiles, which are widely used in construction and various industrial applications. As a non-toxic white pigment, titanium dioxide is prized not only for its ability to enhance the aesthetic appeal of PVC profiles but also for its contribution to the durability and performance of the final product.

Enhancing Aesthetics and Performance

One of the primary reasons manufacturers incorporate titanium dioxide into PVC profiles is to achieve a brilliant white color. This pigment exhibits exceptional hiding power, which allows for a solid and uniform appearance that appeals to consumers. The use of TiO2 helps in producing profiles that maintain their visual appeal even after prolonged exposure to sunlight and weather conditions.

Moreover, titanium dioxide serves as an effective UV stabilizer. PVC profiles are often subjected to harsh environmental conditions, including intense sunlight, which can lead to color fading and degradation over time. The incorporation of titanium dioxide helps mitigate these effects, ensuring that the profiles retain their original color and structural integrity over many years. Therefore, TiO2 not only adds aesthetic value but also significantly extends the lifecycle of PVC products.

Providing Chemical Resistance and Durability

In addition to its aesthetic properties, titanium dioxide contributes to the chemical resistance of PVC profiles. It acts as a barrier that protects the underlying material from harmful substances. This is particularly important in construction applications, where profiles must withstand exposure to various chemicals, moisture, and pollutants. The resilience provided by TiO2 ensures that the profiles remain functional and visually appealing in diverse environments.

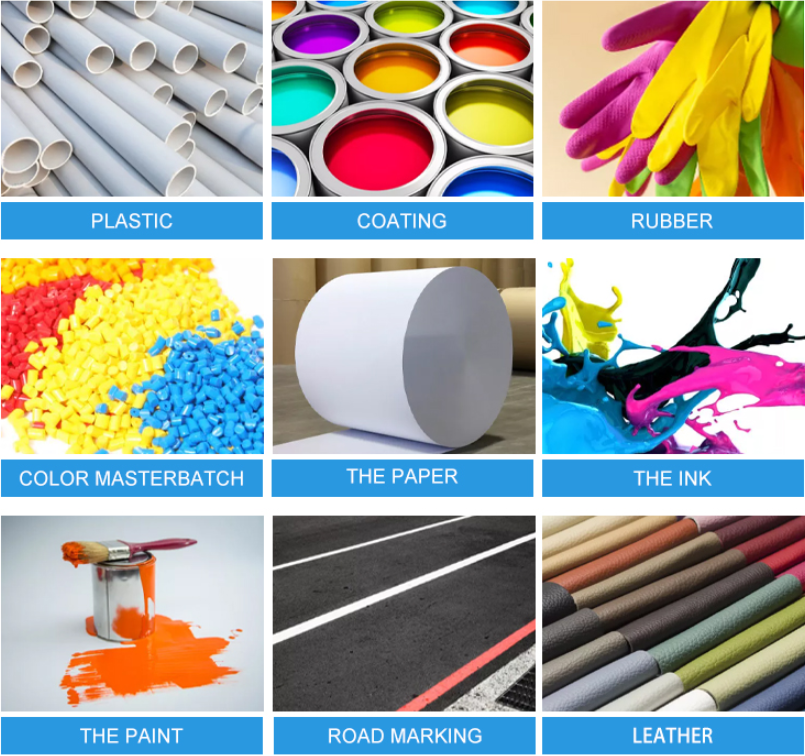

titanium dioxide for pvc profile factory

Furthermore, titanium dioxide can enhance the mechanical properties of PVC. By improving the stiffness and strength of the profiles, TiO2 contributes to their ability to withstand physical stresses. This is crucial in applications where profiles must bear loads or endure impacts, making titanium dioxide a vital component in ensuring performance reliability.

Environmental Considerations

As manufacturers and consumers alike become more conscious of environmental impacts, the use of titanium dioxide also aligns with sustainability goals. TiO2 is a naturally occurring mineral and is considered safe for use in various applications, including those in the building and construction sectors. This makes it a preferable choice compared to synthetic alternatives that may pose health or environmental risks.

In addition, PVC profiles manufactured with titanium dioxide can support energy efficiency standards. By promoting higher solar reflectance, these profiles can contribute to reducing the heat island effect in urban areas, ultimately aiding in energy conservation efforts.

Conclusion

In conclusion, titanium dioxide plays an indispensable role in the production of high-quality PVC profiles. Its multifunctional properties enhance aesthetic appeal, improve durability, and offer chemical resistance that meets the demands of various applications. As the industry continues to evolve, the significance of titanium dioxide in achieving both performance excellence and environmental sustainability will undoubtedly grow. Whether in residential or commercial applications, the benefits of incorporating titanium dioxide into PVC profiles ensure that manufacturers can deliver products that meet consumer expectations for quality, longevity, and environmental responsibility. The future of PVC profile manufacturing will continue to harness the advantages of this remarkable pigment, leading to innovations that better serve the needs of both builders and end-users alike.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025