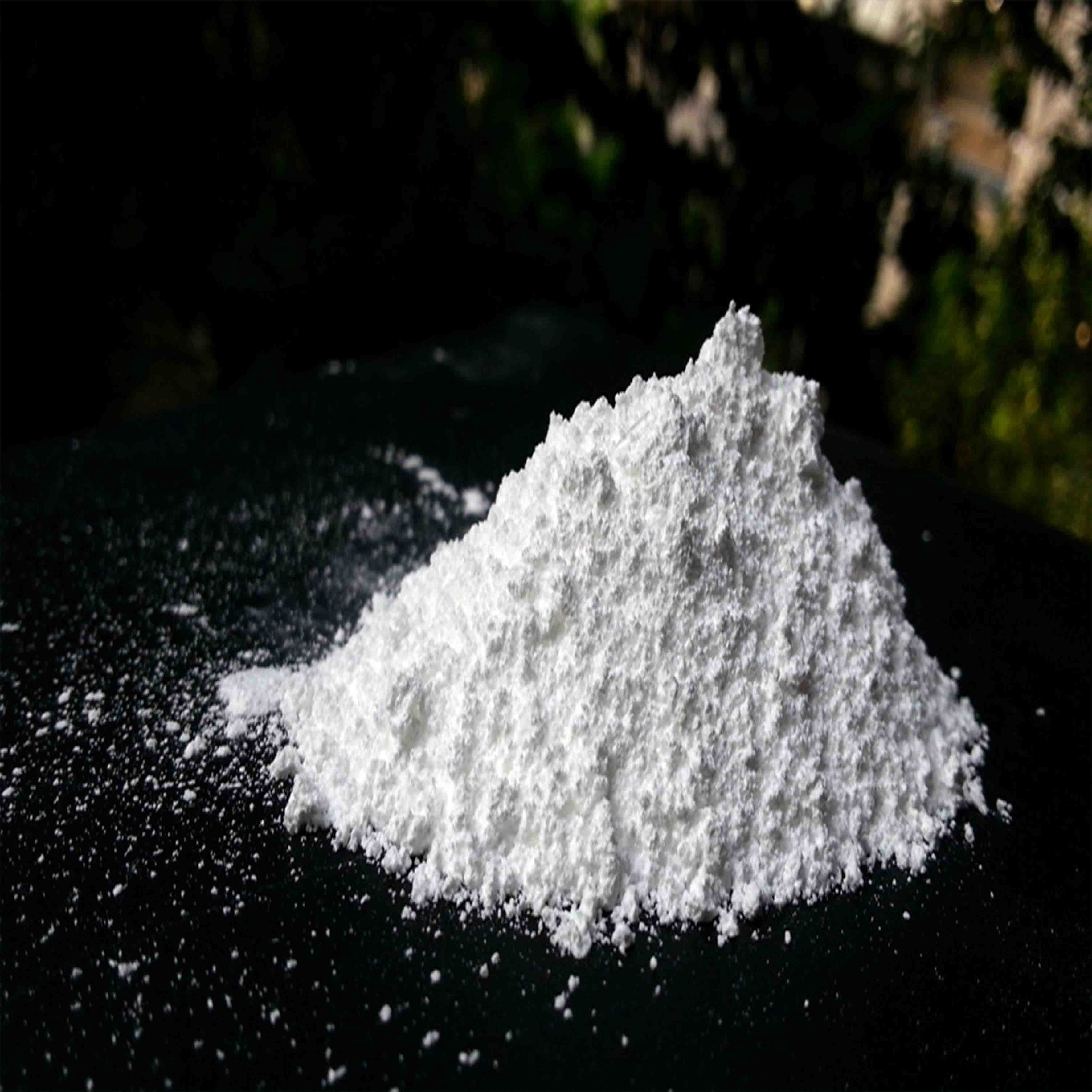

Manufacturers direct sales of inorganic chemical pigment Lide powder

Feb . 16, 2025 12:33 Back to list

Manufacturers direct sales of inorganic chemical pigment Lide powder

Unlocking the Potential of Titanium Dioxide in PVC Profile Manufacturing

Trustworthiness in the application of titanium dioxide in PVC profile manufacturing is bolstered by a commitment to sustainability and safety. The industry is increasingly focused on reducing its environmental footprint, and choosing eco-friendly and responsibly sourced titanium dioxide can significantly contribute to this objective. Manufacturers should leverage suppliers with established reputations for sustainable practices and quality assurance. This not only enhances the credibility of the PVC profiles they produce but also aligns with global efforts to create a more sustainable future. The experience of industry pioneers underscores the transformative impact that titanium dioxide can have on PVC profile production. Companies that have integrated cutting-edge technologies and refined their use of TiO2 have reported improved product durability, customer satisfaction, and market competitiveness. By learning from these industry leaders and continuously updating their knowledge base, PVC profile factories can remain at the forefront of innovation. Embracing titanium dioxide in PVC profile manufacturing is not a mere technical decision; it is a strategic move that can define a company’s market position. The knowledge and application of TiO2 require a holistic approach, considering not only the technical and aesthetic aspects but also environmental and ethical implications. In doing so, manufacturers can produce PVC profiles that are not only visually and structurally superior but also aligned with consumer demands for quality and sustainability. For PVC profile manufacturers, integrating titanium dioxide into their processes with precision and care will continue to yield dividends. As this material continues to evolve and its applications expand, staying informed about breakthroughs and best practices will be crucial. Therefore, establishing a strong foundation in titanium dioxide technology is essential for driving success in a competitive marketplace.

Trustworthiness in the application of titanium dioxide in PVC profile manufacturing is bolstered by a commitment to sustainability and safety. The industry is increasingly focused on reducing its environmental footprint, and choosing eco-friendly and responsibly sourced titanium dioxide can significantly contribute to this objective. Manufacturers should leverage suppliers with established reputations for sustainable practices and quality assurance. This not only enhances the credibility of the PVC profiles they produce but also aligns with global efforts to create a more sustainable future. The experience of industry pioneers underscores the transformative impact that titanium dioxide can have on PVC profile production. Companies that have integrated cutting-edge technologies and refined their use of TiO2 have reported improved product durability, customer satisfaction, and market competitiveness. By learning from these industry leaders and continuously updating their knowledge base, PVC profile factories can remain at the forefront of innovation. Embracing titanium dioxide in PVC profile manufacturing is not a mere technical decision; it is a strategic move that can define a company’s market position. The knowledge and application of TiO2 require a holistic approach, considering not only the technical and aesthetic aspects but also environmental and ethical implications. In doing so, manufacturers can produce PVC profiles that are not only visually and structurally superior but also aligned with consumer demands for quality and sustainability. For PVC profile manufacturers, integrating titanium dioxide into their processes with precision and care will continue to yield dividends. As this material continues to evolve and its applications expand, staying informed about breakthroughs and best practices will be crucial. Therefore, establishing a strong foundation in titanium dioxide technology is essential for driving success in a competitive marketplace.

Latest news

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025