Nov . 22, 2024 09:07 Back to list

titanium dioxide for paint manufacturer

The Role of Titanium Dioxide in the Paint Industry

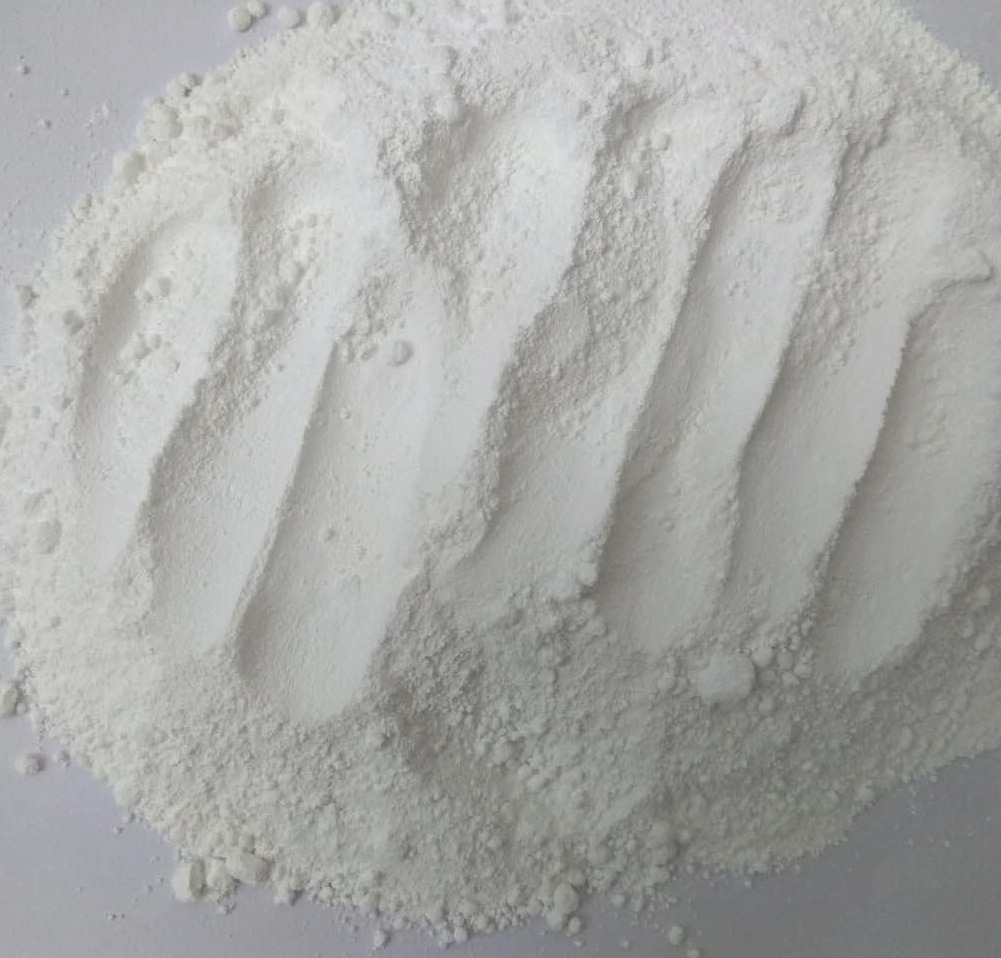

Titanium dioxide (TiO2) plays a crucial role in the paint manufacturing industry, serving as a key pigment that enhances the quality and performance of paints. Its unique properties make it an irreplaceable component in the formulation of various types of coatings, including architectural, industrial, and automotive paints. This article delves into the importance of titanium dioxide for paint manufacturers, exploring its properties, benefits, and the reasons behind its prevalent use.

Understanding Titanium Dioxide

Titanium dioxide is a naturally occurring oxide of titanium, found in various mineral forms. It can be produced synthetically and is known for its exceptional brightness and high refractive index. These characteristics contribute to its outstanding ability to scatter light, giving paints their brilliant white color and opacity. In fact, titanium dioxide is one of the most effective white pigments available, outperforming alternatives such as zinc oxide and lead white in terms of covering power and durability.

Advantages of Titanium Dioxide in Paints

1. Outstanding Opacity and Whiteness The primary advantage of titanium dioxide is its superb opacity, allowing manufacturers to achieve high coverage with minimal application. This leads to cost savings in raw materials and enhances the overall appearance of the paint.

2. UV Resistance TiO2 has excellent UV-blocking properties, which help in protecting the underlying surfaces from degradation caused by ultraviolet radiation. This is particularly beneficial for exterior paints that are exposed to sunlight, ensuring that they maintain their color and performance over time.

3. Durability Paints formulated with titanium dioxide are known for their long-lasting performance. TiO2 enhances the weather resistance of coatings, making them less prone to fading, chalking, and other forms of degradation.

titanium dioxide for paint manufacturer

4. Environmental and Health Safety Titanium dioxide is considered safe for use in various applications, including paints. It is non-toxic and does not release harmful volatile organic compounds (VOCs), making it a preferred choice for eco-friendly formulations.

5. Versatility Titanium dioxide can be used in various types of paints, including water-based and solvent-based systems. Its compatibility with other materials allows for diverse applications across different industries, making it a staple in the paint manufacturing sector.

Challenges and Innovations

While titanium dioxide is a highly effective pigment, the paint industry faces challenges related to its cost and supply. The increasing demand for titanium dioxide has led to fluctuations in price, impacting manufacturers' profit margins. Furthermore, environmental regulations surrounding mining and processing activities are prompting the industry to seek alternative sources and processes.

In response to these challenges, researchers and manufacturers are exploring innovative approaches to enhance the efficiency of titanium dioxide use. This includes improving the dispersion of TiO2 in formulations, developing modified versions of the pigment, and investigating alternative formulations that could reduce dependency on this traditional white pigment while maintaining performance.

Conclusion

Titanium dioxide remains a cornerstone ingredient for paint manufacturers, owing to its superior properties and performance benefits. As the paint industry evolves, the significance of TiO2 in producing high-quality coatings is unlikely to diminish. By continuously exploring new formulations and innovations, manufacturers can harness the strengths of titanium dioxide while addressing the challenges that arise in an ever-changing market. The future of paint manufacturing will undoubtedly continue to be shaped by the enduring relevance of titanium dioxide, ensuring vibrant, durable, and environmentally friendly coatings for diverse applications.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025