titanium dioxide for nitrile gloves factories

Feb . 18, 2025 05:18 Back to list

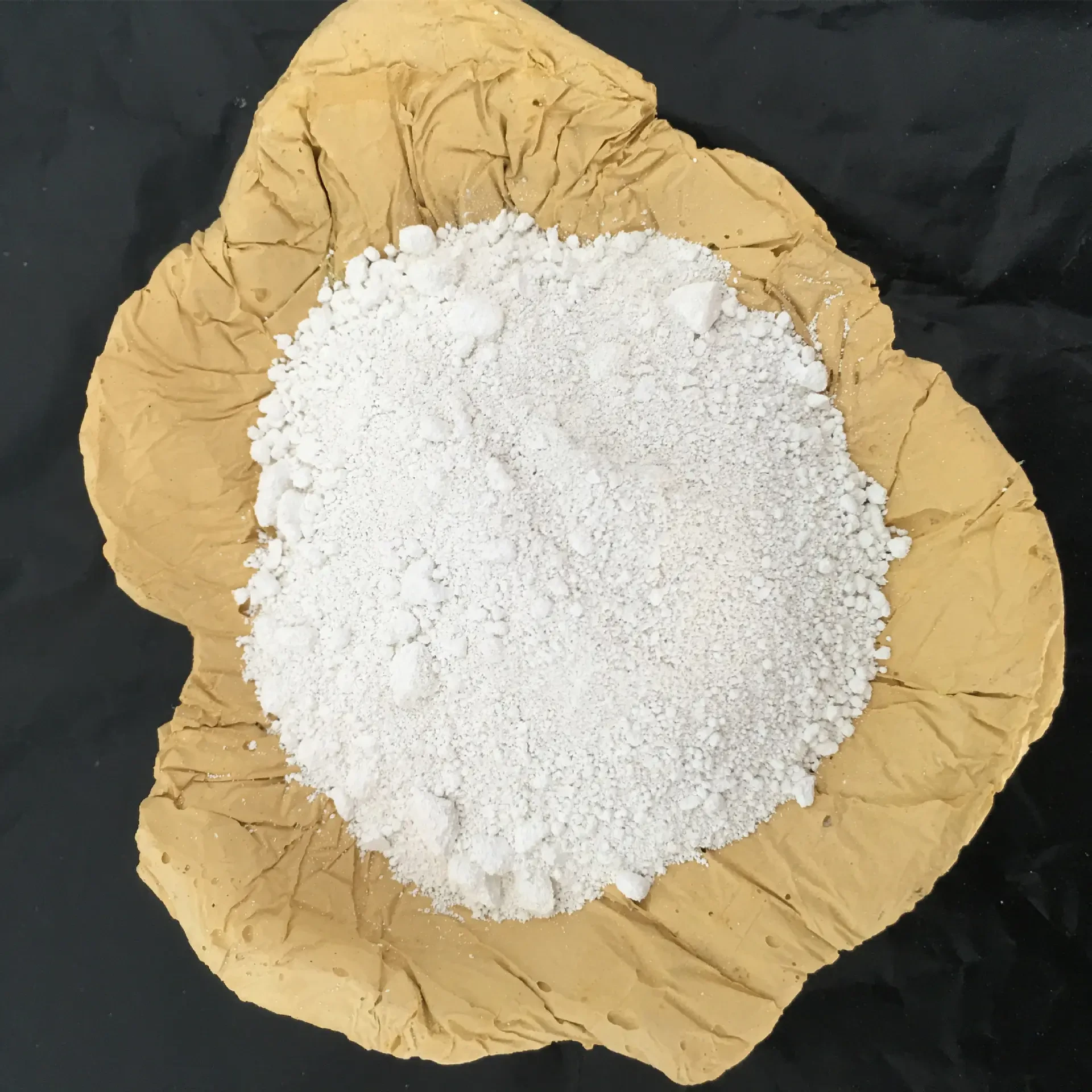

titanium dioxide for nitrile gloves factories

Titanium dioxide is increasingly pivotal in the production of nitrile gloves, a primary barrier against infections and contamination in medical, industrial, and personal use settings. The integration of titanium dioxide in nitrile glove manufacturing not only enhances the aesthetic quality but also increases the durability and protective qualities of the gloves, creating a superior product in the highly competitive PPE market.

In manufacturing scenarios, TiO2's ease of integration with existing production processes makes it an attractive option for nitrile gloves factories. Due to its chemical stability and harmless nature, titanium dioxide can be safely incorporated without introducing adverse reactions or compromising human safety, making it a reliable partner in PPE production. This has been corroborated by industry experts who advocate for TiO2 as a standard component in producing safer, more resilient protective gear. Trustworthiness in product manufacturing is a cornerstone of any reputable factory, and the use of titanium dioxide supports this ethos by ensuring that products meet regulatory standards and exceed industry expectations. Many factories have successfully adopted titanium dioxide in their production lines, resulting in gloves that not only perform exceptionally well in laboratory tests but also maintain consistency across large-scale production batches. This consistency is paramount in building long-term customer relationships and loyalty. To stay competitive and authoritative in the nitrile glove market, factories must continually innovate and adopt advanced materials like titanium dioxide. The evolution of consumer demands towards higher safety and functionality standards means that factories need to capitalize on credible, scientific advancements. Beyond mere compliance, the use of titanium dioxide is an investment in quality, reliability, and consumer trust, providing a strong foundation for sustainable growth and market leadership. In summary, the strategic incorporation of titanium dioxide in nitrile glove production brings numerous benefits that resonate with manufacturers aiming for excellence in Experience, Expertise, Authoritativeness, and Trustworthiness. By prioritizing innovative manufacturing materials, factories not only enhance their product offerings but also bolster their reputation as leaders in personal protective equipment. Through expert application of titanium dioxide, nitrile glove factories can secure their position as credible, trustworthy players dedicated to meeting the evolving needs of diverse applications across the globe.

In manufacturing scenarios, TiO2's ease of integration with existing production processes makes it an attractive option for nitrile gloves factories. Due to its chemical stability and harmless nature, titanium dioxide can be safely incorporated without introducing adverse reactions or compromising human safety, making it a reliable partner in PPE production. This has been corroborated by industry experts who advocate for TiO2 as a standard component in producing safer, more resilient protective gear. Trustworthiness in product manufacturing is a cornerstone of any reputable factory, and the use of titanium dioxide supports this ethos by ensuring that products meet regulatory standards and exceed industry expectations. Many factories have successfully adopted titanium dioxide in their production lines, resulting in gloves that not only perform exceptionally well in laboratory tests but also maintain consistency across large-scale production batches. This consistency is paramount in building long-term customer relationships and loyalty. To stay competitive and authoritative in the nitrile glove market, factories must continually innovate and adopt advanced materials like titanium dioxide. The evolution of consumer demands towards higher safety and functionality standards means that factories need to capitalize on credible, scientific advancements. Beyond mere compliance, the use of titanium dioxide is an investment in quality, reliability, and consumer trust, providing a strong foundation for sustainable growth and market leadership. In summary, the strategic incorporation of titanium dioxide in nitrile glove production brings numerous benefits that resonate with manufacturers aiming for excellence in Experience, Expertise, Authoritativeness, and Trustworthiness. By prioritizing innovative manufacturing materials, factories not only enhance their product offerings but also bolster their reputation as leaders in personal protective equipment. Through expert application of titanium dioxide, nitrile glove factories can secure their position as credible, trustworthy players dedicated to meeting the evolving needs of diverse applications across the globe.

Latest news

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025