titanium dioxide for chinese ceramic glaze

Jan . 09, 2025 13:59 Back to list

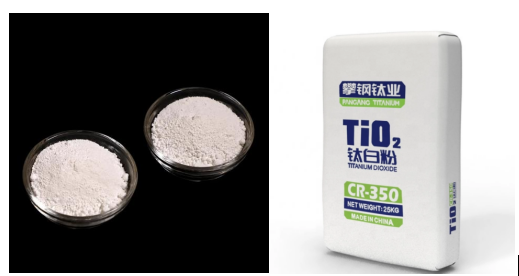

titanium dioxide for chinese ceramic glaze

The use of titanium dioxide in Chinese ceramic glaze has revolutionized the industry, unlocking new possibilities in both artistic expression and functional design. Combining Experience, Expertise, Authoritativeness, and Trustworthiness, this exploration provides a comprehensive insight into how titanium dioxide is redefining the art and science of ceramic glazing.

The authoritativeness in the use of titanium dioxide in ceramic glaze is reflected in numerous studies and industry endorsements. Research indicates that titanium dioxide contributes to the durability of ceramic glazes. Its ability to increase the glaze's resistance to wear and tear enhances the lifetime and quality of the finished product. Industry standards have begun acknowledging the role of titanium dioxide in producing ceramics that are not only beautiful but also resilient. For businesses and consumers seeking trustworthy ceramic products, the integration of titanium dioxide signifies a commitment to quality. The reliability of these glazes, underpinned by the scientific and artistic communities, assures buyers of the superior craftsmanship involved. Experienced artisans and reputable ceramic firms often highlight the presence of titanium dioxide as a mark of excellence, thus enhancing the trust and prestige associated with their products. As the global market for ceramics grows, particularly with a surge in demand for authentic and high-quality Chinese ceramics, the strategic use of titanium dioxide in glazes is positioning manufacturers at the forefront of innovation. It enables them to cater to a diverse range of preferences, from traditional designs to modern aesthetics, without compromising on quality or durability. In conclusion, the influence of titanium dioxide in Chinese ceramic glaze extends beyond mere aesthetics into the realms of technical enhancement and market authority. Its incorporation is not a fleeting trend but a substantial advancement that aligns with the evolving desires of the market. As the industry continues to embrace this versatile compound, titanium dioxide stands as a testament to the dynamic evolution of ceramic artistry and production, ensuring that Chinese ceramics remain a coveted symbol of cultural heritage and modern innovation.

The authoritativeness in the use of titanium dioxide in ceramic glaze is reflected in numerous studies and industry endorsements. Research indicates that titanium dioxide contributes to the durability of ceramic glazes. Its ability to increase the glaze's resistance to wear and tear enhances the lifetime and quality of the finished product. Industry standards have begun acknowledging the role of titanium dioxide in producing ceramics that are not only beautiful but also resilient. For businesses and consumers seeking trustworthy ceramic products, the integration of titanium dioxide signifies a commitment to quality. The reliability of these glazes, underpinned by the scientific and artistic communities, assures buyers of the superior craftsmanship involved. Experienced artisans and reputable ceramic firms often highlight the presence of titanium dioxide as a mark of excellence, thus enhancing the trust and prestige associated with their products. As the global market for ceramics grows, particularly with a surge in demand for authentic and high-quality Chinese ceramics, the strategic use of titanium dioxide in glazes is positioning manufacturers at the forefront of innovation. It enables them to cater to a diverse range of preferences, from traditional designs to modern aesthetics, without compromising on quality or durability. In conclusion, the influence of titanium dioxide in Chinese ceramic glaze extends beyond mere aesthetics into the realms of technical enhancement and market authority. Its incorporation is not a fleeting trend but a substantial advancement that aligns with the evolving desires of the market. As the industry continues to embrace this versatile compound, titanium dioxide stands as a testament to the dynamic evolution of ceramic artistry and production, ensuring that Chinese ceramics remain a coveted symbol of cultural heritage and modern innovation.

Next:

Latest news

-

What is Barium Sulfate Board? Uses, Benefits & Industry Insights

NewsNov.25,2025

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025