titanium dioxide factory

Jan . 30, 2025 02:25 Back to list

titanium dioxide factory

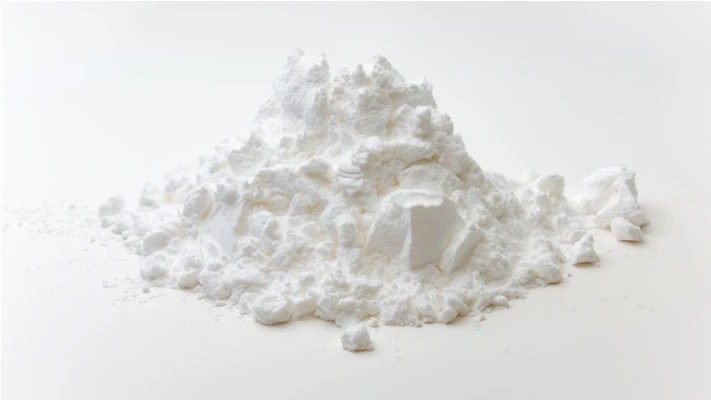

The process of manufacturing titanium dioxide is a fascinating journey that marries complex chemistry with precision engineering, resulting in a versatile and essential product for numerous industries worldwide. Titanium dioxide (TiO2) is renowned for its pigmentary properties, enhancing the whiteness and brightness of products ranging from paints and coatings to plastics and paper. As a centerpiece in industrial processes, understanding the meticulous operation of a titanium dioxide factory offers valuable insights into its critical role and the rigorous standards imposed to ensure quality and sustainability.

The resultant titanium dioxide must meet meticulous quality standards before proceeding to the finishing stages. This verification ensures the material's pigmentary properties, including brightness, tinting strength, and particle size distribution, meet industry expectations. The primary characteristic of titanium dioxide—its unparalleled opacity—depends significantly on these attributes. Thus, sophisticated technologies, such as particle size analyzers and spectroscopy, are employed to ascertain these critical properties. Titanium dioxide factories emphasize sustainability and environmental responsibility. Recognizing the environmental concerns associated with industrial manufacturing, many facilities have implemented closed-loop systems, recycling and reusing water and reducing emissions through advanced scrubbers and filters. These initiatives not only align with global environmental directives but also reflect the industry's commitment to sustainable practices. An authoritative factory differentiates itself by adhering to international safety and quality standards, such as ISO certifications, which affirm its commitment to excellence and reliability. By maintaining a rigorous quality management system and investing in continuous personnel training, these facilities bolster their reputation within the global market. Collaborations with research institutions further enhance expertise, driving the development of innovative applications for titanium dioxide, like photocatalytic coatings, which assist in neutralizing pollutants. In summary, a titanium dioxide factory exemplifies a synthesis of scientific mastery and environmental stewardship. From the selection of premium raw materials to the application of cutting-edge production techniques, each phase underscores the authenticity and professionalism that defines the industry. The seamless integration of innovation and tradition ensures the delivery of superior products that meet both industry standards and consumer expectations. As the demand for titanium dioxide continues to rise, these factories symbolize a commitment to quality, authority, and sustainability, securing their position as pivotal players in the manufacturing landscape.

The resultant titanium dioxide must meet meticulous quality standards before proceeding to the finishing stages. This verification ensures the material's pigmentary properties, including brightness, tinting strength, and particle size distribution, meet industry expectations. The primary characteristic of titanium dioxide—its unparalleled opacity—depends significantly on these attributes. Thus, sophisticated technologies, such as particle size analyzers and spectroscopy, are employed to ascertain these critical properties. Titanium dioxide factories emphasize sustainability and environmental responsibility. Recognizing the environmental concerns associated with industrial manufacturing, many facilities have implemented closed-loop systems, recycling and reusing water and reducing emissions through advanced scrubbers and filters. These initiatives not only align with global environmental directives but also reflect the industry's commitment to sustainable practices. An authoritative factory differentiates itself by adhering to international safety and quality standards, such as ISO certifications, which affirm its commitment to excellence and reliability. By maintaining a rigorous quality management system and investing in continuous personnel training, these facilities bolster their reputation within the global market. Collaborations with research institutions further enhance expertise, driving the development of innovative applications for titanium dioxide, like photocatalytic coatings, which assist in neutralizing pollutants. In summary, a titanium dioxide factory exemplifies a synthesis of scientific mastery and environmental stewardship. From the selection of premium raw materials to the application of cutting-edge production techniques, each phase underscores the authenticity and professionalism that defines the industry. The seamless integration of innovation and tradition ensures the delivery of superior products that meet both industry standards and consumer expectations. As the demand for titanium dioxide continues to rise, these factories symbolize a commitment to quality, authority, and sustainability, securing their position as pivotal players in the manufacturing landscape.

Latest news

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025