Sep . 23, 2024 06:57 Back to list

titanium dioxide color factories

The Role of Titanium Dioxide in Industrial Color Production

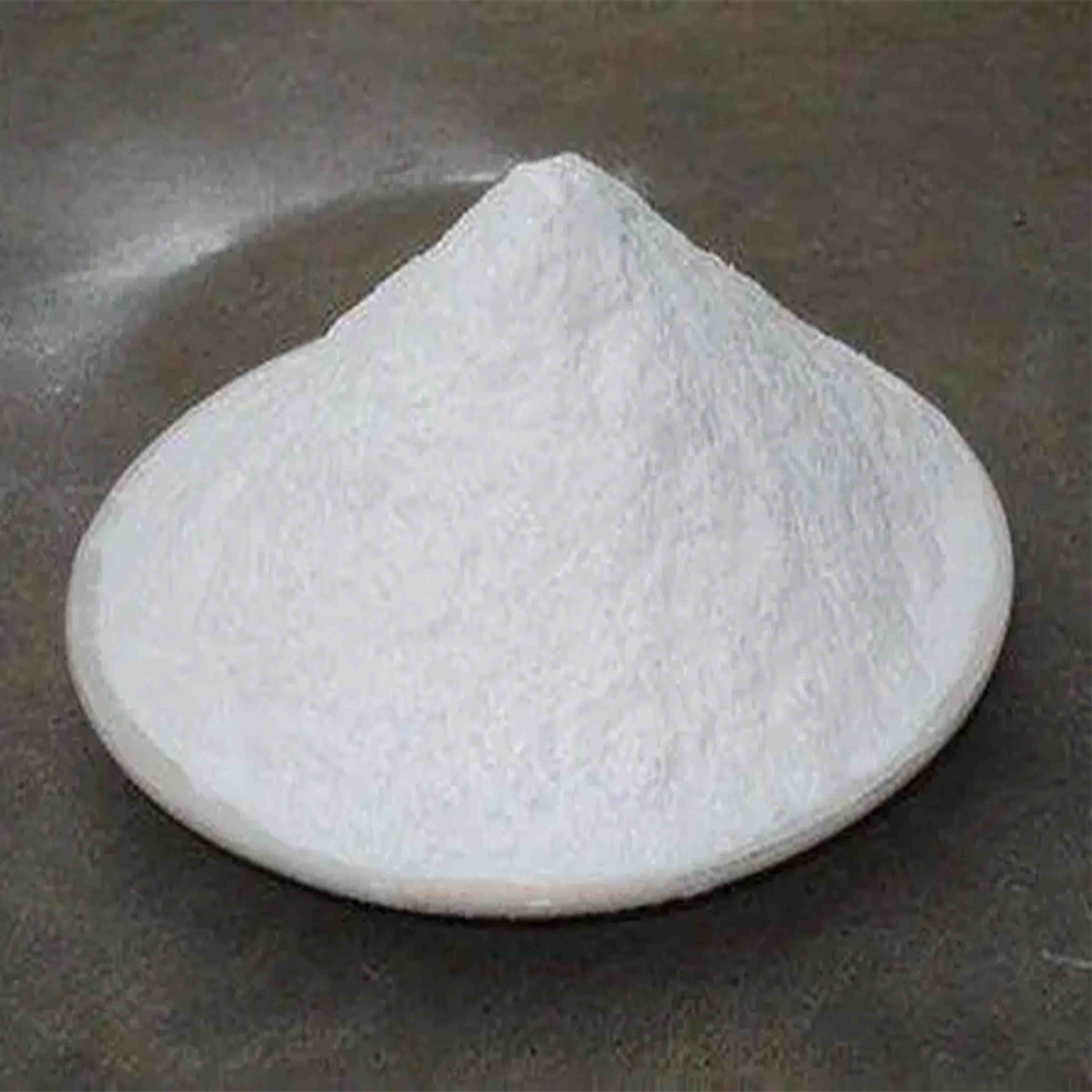

Titanium dioxide (TiO2) is one of the most widely used white pigments in the world, known for its brightness, opacity, and durability. Its significance in the color industry cannot be overstated, as it plays an essential role in various applications, including paints, coatings, plastics, and cosmetics. This article explores the properties of titanium dioxide, its manufacturing process, and its importance in color factories.

The Role of Titanium Dioxide in Industrial Color Production

The production of titanium dioxide occurs through two main processes the sulfate process and the chloride process. The sulfate process involves the reaction of titanium ore with sulfuric acid, which yields titanium sulfate. Following this, titanium dioxide is precipitated, washed, and calcined to produce the final pigment. The chloride process, on the other hand, uses high-purity titanium feedstocks and involves chlorination at high temperatures, resulting in a purer and more expensive product. Each method has its advantages and is chosen based on the desired characteristics of the TiO2 produced.

titanium dioxide color factories

In color factories, titanium dioxide is mixed with various resins, solvents, and additives to create a variety of paints and coatings. It is prized for its non-toxic nature, making it suitable for use in products intended for consumer safety. The durability of titanium dioxide also means that it withstands UV radiation, weathering, and chemical exposure, ensuring that the colors remain vibrant over time. Furthermore, its high opacity allows paint manufacturers to use less volume of pigment while achieving the same level of coverage, which can lead to cost savings.

The use of titanium dioxide goes beyond industrial applications; it is also prevalent in cosmetic products. Sunscreens, for example, often employ TiO2 due to its ability to block UV rays effectively. In this realm, its safety profile is a significant selling point, as consumers seek products that protect their skin without harmful effects.

Despite its many advantages, the titanium dioxide industry faces challenges. Environmental concerns regarding the extraction process and the potential health risks associated with inhaling TiO2 particles have led to increased scrutiny. As a result, factories are striving to adopt more sustainable practices and regulations to ensure a balance between industrial use and environmental responsibility.

In conclusion, titanium dioxide is a vital component of the color industry, offering unique properties that enhance the aesthetic and protective qualities of many products. Its versatile applications in various sectors underscore its importance, while ongoing efforts to address environmental and health concerns illustrate the industry's commitment to sustainable practices. As technology and regulations evolve, titanium dioxide will continue to play a critical role in the future of color production.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025