Aug . 09, 2024 04:45 Back to list

Titanium Dioxide Suppliers for High-Quality Paint Applications and Their Benefits in Coatings

The Role of Titanium Dioxide in the Paint Industry A Supplier's Perspective

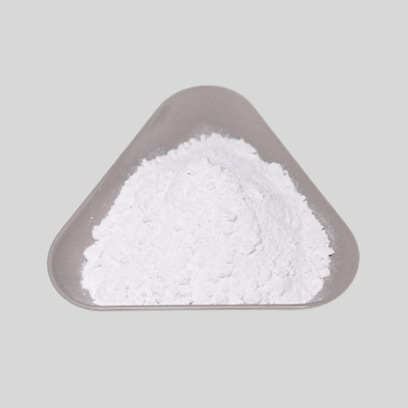

Titanium dioxide (TiO2) has long been a cornerstone in the paint industry, celebrated for its exceptional properties and versatility. As a pigment, it provides opacity, brightness, and durability, making it a crucial ingredient in various types of paints, including decorative, protective, and industrial coatings. This article explores the significance of titanium dioxide used in paint and highlights the role of suppliers in ensuring its availability and quality.

Understanding Titanium Dioxide

Titanium dioxide is a white, powdery substance derived from the mineral rutile or ilmenite. It is renowned for its high refractive index and strong ultraviolet (UV) light absorption capabilities. These characteristics impart exceptional whiteness and opacity in paints, making them more vibrant and visually appealing. The pigment is also known for its resistance to fading, chalking, and degradation under UV exposure, which is essential for outdoor applications.

Applications in the Paint Industry

In the paint industry, titanium dioxide serves multiple purposes. Its primary application is as a pigment, where it enhances the color and brightness of the paint while providing uniform coverage. This is particularly important for architectural paints, where aesthetics play a vital role in consumer choice. Additionally, TiO2 contributes to the durability of paint films, offering long-lasting protection against environmental factors.

Moreover, various formulations of titanium dioxide are used in specialized coatings. For instance, in automotive paints, TiO2 helps achieve a glossy finish and enhances scratch resistance. In protective coatings, it plays a crucial role in preventing corrosion and extending the lifespan of surfaces. The versatility of titanium dioxide makes it suitable for a wide range of applications, from residential homes to industrial structures.

Supplier's Role in Quality and Availability

tio2 used in paint supplier

The role of suppliers in the paint industry cannot be overstated. They are responsible for sourcing high-quality titanium dioxide that meets the specific needs of manufacturers. The supply chain for TiO2 is complex, involving mining, processing, and distribution. Suppliers must ensure that the titanium dioxide they provide is not only of superior quality but also compliant with environmental regulations.

Quality control is paramount, as variations in the purity and particle size of titanium dioxide can significantly affect the performance of the final paint products. Suppliers often collaborate closely with paint manufacturers to understand their requirements and provide tailored solutions. This partnership is essential for developing innovative paint products that meet the evolving demands of the market.

Environmental Considerations

As the paint industry faces increasing scrutiny over environmental concerns, suppliers of titanium dioxide are also adapting to these challenges. The extraction and production of TiO2 can have significant environmental impacts, leading to a push for sustainable practices. Many suppliers are investing in cleaner production methods and alternative sources of titanium dioxide, such as those derived from sustainable materials.

Furthermore, the development of TiO2 in nano-form has opened new avenues for enhancing paint properties while reducing the overall material usage. Suppliers who prioritize sustainability not only contribute to environmental conservation but also align themselves with the growing consumer demand for eco-friendly products.

Conclusion

Titanium dioxide remains an indispensable component of the paint industry, providing essential qualities such as opacity, brightness, and durability. Suppliers play a vital role in ensuring the availability and quality of TiO2, enabling paint manufacturers to develop high-performance products that meet market demands. As the industry evolves, the focus on sustainability and innovation presents exciting opportunities for both suppliers and manufacturers in the quest for superior paint solutions. The future of the paint industry, with titanium dioxide at its core, looks bright and promising.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025