Oct . 27, 2025 00:40 Back to list

Titanium Dioxide - High Purity, Brightness, Bulk Prices

Titanium Dioxide is a key solution in the manufacturing industry, specifically within Chemical raw material and chemical product manufacturing industry and Manufacturing of basic chemical raw materials. This article explores how Hebei Caiqing New Material Technology Co., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Titanium Dioxide Overview

- Benefits & Use Cases of Titanium Dioxide in Manufacturing of basic chemical raw materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Titanium Dioxide from Hebei Caiqing New Material Technology Co., LTD

Titanium Dioxide Overview

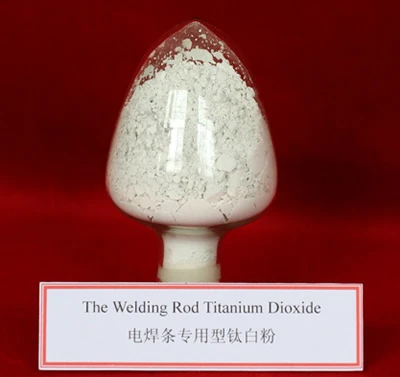

Titanium Dioxide (TiO2) is the workhorse white pigment and functional mineral across the Chemical raw material and chemical product manufacturing industry. With a refractive index of ~2.7 and tightly controlled particle size, it delivers exceptional opacity, brightness, and UV resistance. In basic chemical raw materials manufacturing, it functions as an opacifier, whitening agent, UV screen, and rheology contributor in coatings, plastics, paper, inks, rubber, and welding consumables. Hebei Caiqing New Material Technology Co., LTD supplies high-purity rutile TiO2 engineered for demanding B2B applications, including electric welding rod fluxes where stable arc characteristics and clean slag release are critical.

- Technical notes: typical TiO2 content ≥94%, rutile crystal form, average particle size D50 ≈ 0.25–0.35 μm, oil absorption 18–22 g/100 g, moisture ≤0.5%, pH (aqueous slurry) 6.5–8.5. Surface treatment options with alumina/silica (SA) improve dispersion and durability.

- Case example: A regional E6013 electrode plant reformulated with Caiqing rutile TiO2 and recorded faster slag release and a 12% reduction in post-weld cleaning time, while maintaining consistent bead profile and lower spatter.

- Reliability: Hebei Caiqing’s process control and COA traceability support tight batch-to-batch consistency demanded by high-throughput manufacturing—ideal when buyers search for “titanium dioxide use,” “titanium dioxide 298,” or “ttk titanium dioxide” benchmarks.

Benefits & Use Cases of Titanium Dioxide in Manufacturing of basic chemical raw materials

Across coatings, masterbatch, PVC, paper, inks, and welding electrodes, Titanium Dioxide is prized for hiding power, high L brightness (often called l titanium dioxide in QC parlance), photostability, and chemical inertness. In electrode fluxes (e.g., E6013), TiO2 enhances arc stability and slag fluidity; in paints and plastics it reduces film thickness at equal opacity, cutting resin demand. Caiqing supplies surface-treated rutile grades (SA) for superior dispersion and weatherability, and untreated options for specialized compounding.

- Applications: architectural and industrial coatings, PP/PE masterbatch, PVC profiles, paper filling/coating, gravure/flexo inks, rubber goods, and welding consumables. For buyers comparing specifications, Caiqing grades align with common market references like “titanium dioxide 298” while offering robust supply assurance.

- Competitive advantages: high opacity per unit mass (lower dosage), fast wet-in and dispersion, controlled pH for broad binder compatibility (titanium dioxide ph), and excellent whiteness retention. These translate into fewer grind passes and more uniform film build.

- Sector expertise: Hebei Caiqing partners with customers to dial-in TiO2 selection (T-series for tinting strength, E-focused for electrode/welding, SA-treated for exterior durability), answering market searches like titanium dioxide t, titanium dioxide e, and titanium dioxide sa.

Cost, Maintenance & User Experience

Total cost of ownership with Titanium Dioxide depends on opacity efficiency, dispersion energy, and film durability. Caiqing’s rutile TiO2 improves hiding power so formulators can reduce pigment volume concentration or resin usage, lowering per-unit material costs. Efficient wet-in shortens milling time, cutting energy consumption and increasing throughput. For welding electrodes, stable TiO2 quality reduces rework and downtime—key ROI drivers in continuous operations.

- Durability & ROI: Customers in coatings and plastics often report 5–10% dosage optimization and process energy savings, delivering payback within a typical 6–12 month window after standardizing on a single TiO2 grade. Packaging is available in 25 kg bags and 1,000 kg super sacks to streamline handling.

- User feedback: Producers cite consistent whiteness and gloss, minimal filter/blade wear, and stable pH in aqueous systems. Welding customers note smoother slag and arc behavior. Search trends like “titanium dioxide use,” “buy titanium dioxide,” and “titanium dioxide 298” reflect the emphasis on performance and supply reliability in selection decisions.

Sustainability & Market Trends in manufacturing

Sustainability priorities are reshaping TiO2 sourcing and use—from energy efficiency and waste minimization to safer handling of fine powders. Regulatory frameworks such as REACH and regional worker-safety standards focus on dust control and safe storage. Manufacturers also prioritize pigments that enable thinner films and longer service life to reduce lifecycle impacts. The market continues to move toward high-purity, surface-engineered rutile grades that deliver durability with lower total material usage.

- Hebei Caiqing’s approach: optimized milling and classification for energy efficiency, silica/alumina (SA) surface treatments for extended product life in exterior applications, closed handling and dust mitigation, and bulk-pack options that reduce packaging waste. Digital COAs and batch traceability support compliance and audits.

- Market pulse: Buyers searching for ttk titanium dioxide, titanium dioxide 298, titanium dioxide 12, or titanium dioxide t/e variants are converging on quality, consistency, and verified sustainability data. Caiqing aligns product development to these trends, helping customers meet performance targets and ESG goals simultaneously.

Conclusion on Titanium Dioxide from Hebei Caiqing New Material Technology Co., LTD

Titanium Dioxide remains an essential raw material in the Chemical raw material and chemical product manufacturing industry, delivering opacity, brightness, durability, and process efficiency across coatings, plastics, paper, inks, and welding electrodes. Hebei Caiqing New Material Technology Co., LTD combines dependable quality with technical support and sustainable practices, making it a trusted partner for high-volume manufacturers who are ready to buy titanium dioxide with confidence.

- Count on consistent performance, optimized dispersion, and strong ROI from Caiqing’s TiO2 portfolio.

- Reputation built on reliability, responsiveness, and application know-how.

- Contact us: email: sales01@cqtitaniumdioxide.com — Visit our website: https://www.cqtitaniumdioxide.com

-

Comprehensive Guide to Lithopone ZnS-BaSO4 Quotes – Pricing, Applications & Industry Insights

NewsNov.21,2025

-

Titanium Dioxide for Ceramics: Enhancing Durability, Sustainability & Innovation

NewsNov.21,2025

-

Titanium Dioxide for Tires | Enhancing Durability and Sustainability in Tire Manufacturing

NewsNov.20,2025

-

Titanium Dioxide for Rubber: Enhancing Durability and Performance Worldwide

NewsNov.20,2025

-

Get Reliable Lithopone(b301 b311) Quotes: Quality, Specs & Supplier Insights

NewsNov.20,2025

-

Lithopone B311 B301 Quotes: Essential Guide to Global Pigment Pricing & Applications

NewsNov.20,2025