Nov . 02, 2025 00:35 Back to list

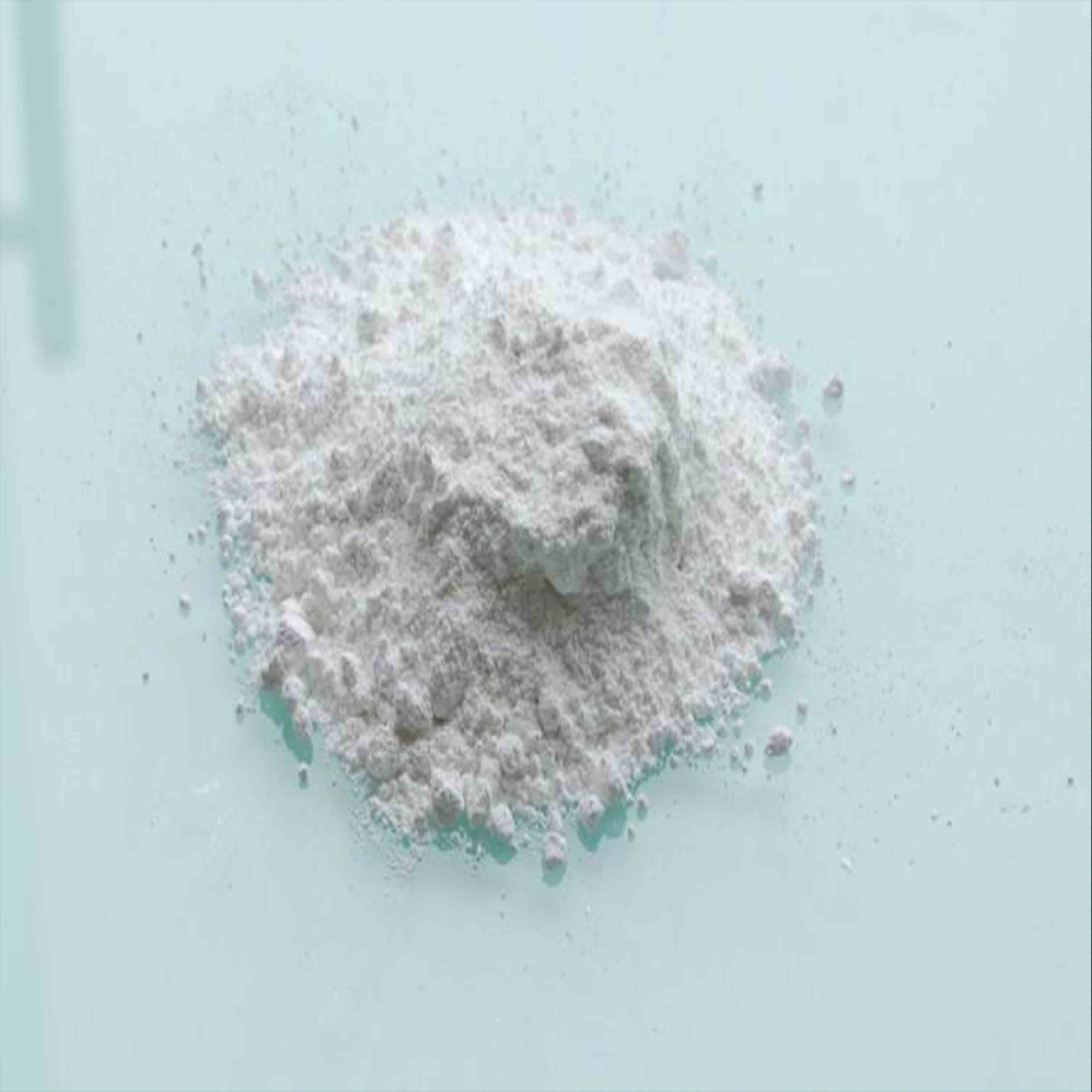

Titanium Dioxide CO2: High Whiteness, UV Shield, Low Cost

Titanium Dioxide Co2 is a key solution in the manufacturing industry, specifically within Chemical raw material and chemical product manufacturing industry and Manufacturing of pigments, dyes, and similar products. This article explores how Hebei Caiqing New Material Technology Co., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Titanium Dioxide Co2 Overview

- Benefits & Use Cases of Titanium Dioxide Co2 in Manufacturing of pigments, dyes, and similar products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Titanium Dioxide Co2 from Hebei Caiqing New Material Technology Co., LTD

Titanium Dioxide Co2 Overview

In B2B manufacturing, Titanium Dioxide Co2 often refers to the CO2 footprint considerations around titanium dioxide (TiO2) selection and use. TiO2 (CAS: 13463-67-7) is the industry’s benchmark white pigment (Pigment White 6) celebrated for exceptional brightness, opacity, and UV durability. Hebei Caiqing New Material Technology Co., LTD supplies rutile grades such as 6618 titanium dioxide, engineered for coatings, plastics, inks, and paper where high tint strength, clean undertone, and dispersion stability are critical. Typical rutile features include optimal submicron particle size for scattering efficiency, high refractive index (~2.7), and surface treatments (e.g., alumina/zirconia/organic) that enhance weatherability and processing—consult the official TDS for exact parameters.

- Relevance: A core input across Chemical raw material and chemical product manufacturing industry and the Manufacturing of pigments, dyes, and similar products for hiding power, whiteness, and gloss.

- Technical notes: Controlled particle size distribution, robust dispersion in solvent- and water-borne systems, and strong tinting strength that enables dosage optimization.

- Market context: Buyers may see codes like titanium dioxide 171 (E171 in certain contexts), titanium dioxide 298, and brand names such as TTK titanium dioxide; Hebei Caiqing’s rutile R6618 targets consistent quality for industrial applications.

- Manufacturer credibility: Hebei Caiqing New Material Technology Co., LTD is a reliable supplier focused on stable supply, technical support, and rigorous QC for TiO2 pigments.

Benefits & Use Cases of Titanium Dioxide Co2 in Manufacturing of pigments, dyes, and similar products

Manufacturing leaders select TiO2 to maximize hiding power, whiteness, and durability across coatings, plastics, masterbatch, inks, paper, and sealants. In color systems and “titanium dioxide dye” formulations, rutile TiO2 acts as a high-opacity white pigment backbone that sets the gloss and undertone for the finished product. Hebei Caiqing’s rutile R6618 aligns with demanding applications: industrial and architectural coatings (interior/exterior), powder coatings, PVC profiles, PP/PE masterbatch, offset and gravure inks, and paper coating where smoothness, brightness, and printability matter.

- Key features: Strong tint strength, excellent dispersion, good blue undertone, and weather resistance for long-term color retention and reduced chalking.

- Competitive advantages: Consistency lot-to-lot, process-friendly viscosity behavior, and compatibility with common resin systems—supporting efficient milling and energy savings.

- Expertise: Hebei Caiqing provides application guidance—from pigment selection to formulation tips—so buyers can translate “titanium dioxide uses” into measurable performance in their specific lines.

Cost, Maintenance & User Experience

The total cost of ownership (TCO) for TiO2 is not only the invoice price; it includes dispersion time, energy use, waste/scrap, film durability, and repaint or replacement cycles. Choosing a high-tint-strength rutile like R6618 enables lower dosage at equal opacity, improving “titanium dioxide cost” efficiency. Ease of dispersion reduces milling passes and viscosity adjustments, cutting labor and additives. In end-use, durable UV and weather resistance help extend life—especially in exterior coatings and outdoor plastics—lowering lifecycle costs and enhancing ROI.

- Cost drivers: Feedstock (ilmenite/rutile), energy, processing route, logistics, and packaging. Strategic sourcing and consistent quality protect margins in volatile markets.

- User feedback themes: Stable whiteness, predictable dispersion, and reliable hiding power translate to repeatable production outcomes and fewer corrective actions in the Chemical raw material and chemical product manufacturing industry.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping pigment procurement. Buyers now assess Titanium Dioxide Co2 metrics—energy intensity, process route, and logistics footprint—alongside performance. Regulatory frameworks (e.g., REACH in the EU and region-specific chemical regulations) elevate expectations for documentation, safe handling, and traceability. In parallel, brands are targeting reduced Scope 3 emissions, so pigments that maintain opacity at lower dosage or extend product life are advantageous in LCA terms. Food-related regulations around “titanium dioxide 171” underscore the need to match grade and application correctly; for industrial coatings, plastics, and inks, high-purity rutile remains a mainstay.

- Industry growth: Ongoing demand from infrastructure, packaging, and industrial goods continues to drive TiO2 consumption, with buyers comparing grades (e.g., 6618 titanium dioxide or market names like TTK titanium dioxide) on both performance and environmental profile.

- Hebei Caiqing’s stance: Forward-looking on quality assurance, documentation (COA/SDS), and responsible sourcing, the company supports customers’ sustainability goals by enabling durable, efficient formulations that help reduce wastage and potential CO2 impact across the value chain.

Conclusion on Titanium Dioxide Co2 from Hebei Caiqing New Material Technology Co., LTD

For B2B producers in the Manufacturing of pigments, dyes, and similar products, Titanium Dioxide Co2 considerations highlight the need for a pigment that delivers opacity, durability, and process efficiency with a keen eye on lifecycle impact. Hebei Caiqing New Material Technology Co., LTD’s rutile solutions—such as R6618—offer consistent quality and technical support to help teams optimize dosage, throughput, and final product performance.

- Value recap: High tint strength, reliable dispersion, and robust weatherability for coatings, plastics, inks, and paper.

- Supplier trust: Hebei Caiqing is committed to quality, documentation, and responsive service.

- Strong CTA: Contact us: email: sales01@cqtitaniumdioxide.com — Visit our website: https://www.cqtitaniumdioxide.com

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025