Sep . 07, 2024 19:53 Back to list

High-Quality Titanium Dioxide (TiO2) Manufacturer at 298°K

Understanding Titanium Dioxide 298 A Comprehensive Overview of Its Manufacturing Process

Titanium dioxide (TiO2), particularly in the form labeled as Titanium Dioxide 298, has garnered significant attention across various industries. Renowned for its excellent opacity, brightness, and UV resistance, TiO2 is predominantly used as a white pigment in paints, coatings, plastics, and cosmetics. This article delves into the key aspects of Titanium Dioxide 298, focusing on its manufacturing processes and applications.

The Manufacturing Process

The production of Titanium Dioxide 298 begins with its primary raw material, ilmenite (FeTiO3) or rutile (TiO2). The choice of feedstock significantly influences the quality and purity of the final product. The manufacturing process typically involves several key steps

1. Ore Concentration The first step is to extract titanium ore from the earth, which is then concentrated to eliminate impurities. This is often accomplished through physical and chemical separation techniques.

2. Sulfate or Chloride Process There are two principal methods for converting titanium ore into TiO2 the sulfate process and the chloride process. The sulfate process involves digesting the ore in sulfuric acid, yielding titanium sulfate, which is then hydrolyzed to produce TiO2. Conversely, the chloride process entails reacting the titanium ore with chlorine to produce titanium tetrachloride (TiCl4), which is subsequently oxidized to produce high-purity TiO2. The choice between these methods often depends on the desired quality and specifications of the end product.

3. Purification After titanium dioxide is synthesized, it undergoes extensive purification processes to remove contaminants. This step is crucial, as the purity of TiO2 directly influences its performance in applications.

4. Crystallization and Calcination The TiO2 particles are often crystallized and then subjected to calcination at high temperatures. This process improves the properties of the titanium dioxide, enhancing its brightness and opacity.

5. Surface Treatment To enhance its dispersive properties and performance in applications, Titanium Dioxide 298 may undergo surface treatments with various chemicals. This step helps to improve its stability and compatibility with other materials.

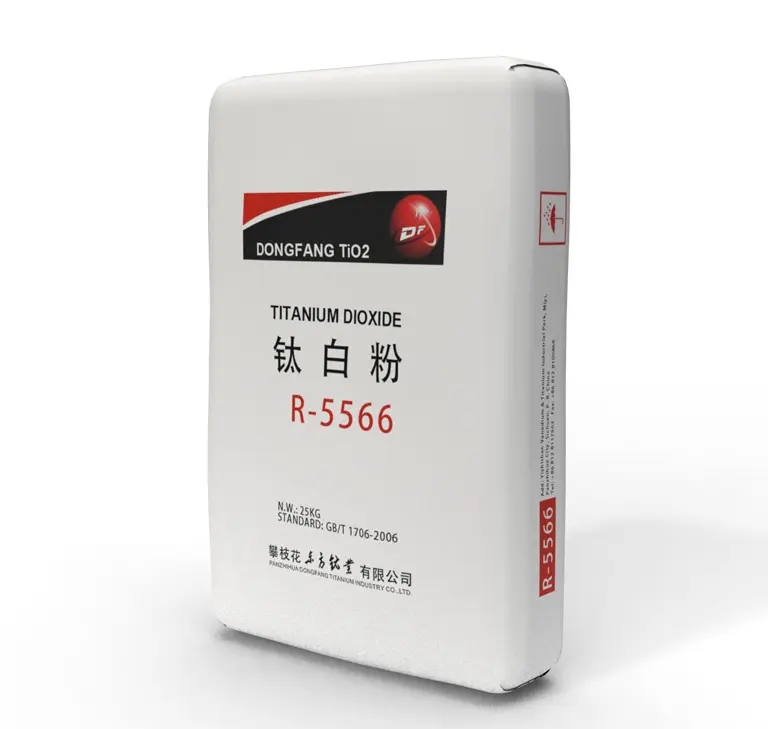

titanium dioxide 298 manufacturer

Applications of Titanium Dioxide 298

Titanium Dioxide 298's exceptional properties make it a versatile material across several industries. Its most notable applications include

- Paints and Coatings Due to its high opacity and durability, TiO2 is a preferred choice for manufacturers of paints and coatings, ensuring vibrant colors and long-lasting finishes.

- Plastics and Polymers In the plastics industry, TiO2 is used to enhance the whiteness and UV resistance of polymer products, making them suitable for outdoor applications.

- Cosmetics TiO2 is widely used in cosmetics, such as foundations and sunscreens, due to its ability to provide sun protection and a flawless finish.

- Food Industry In certain regions, food-grade titanium dioxide is used as a food coloring agent, helping to enhance the appearance of various products.

Conclusion

Titanium Dioxide 298 is more than just a pigment; it represents a crucial component in numerous industrial applications. The intricate manufacturing processes ensure that it meets the stringent demands of quality and performance. As industries continue to innovate, the role of Titanium Dioxide 298 is set to expand, making it a material of choice for the future.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025