Dec . 06, 2024 12:01 Back to list

tio2 white pigment factory

The TiO2 White Pigment Factory A Key Player in Modern Industrial Applications

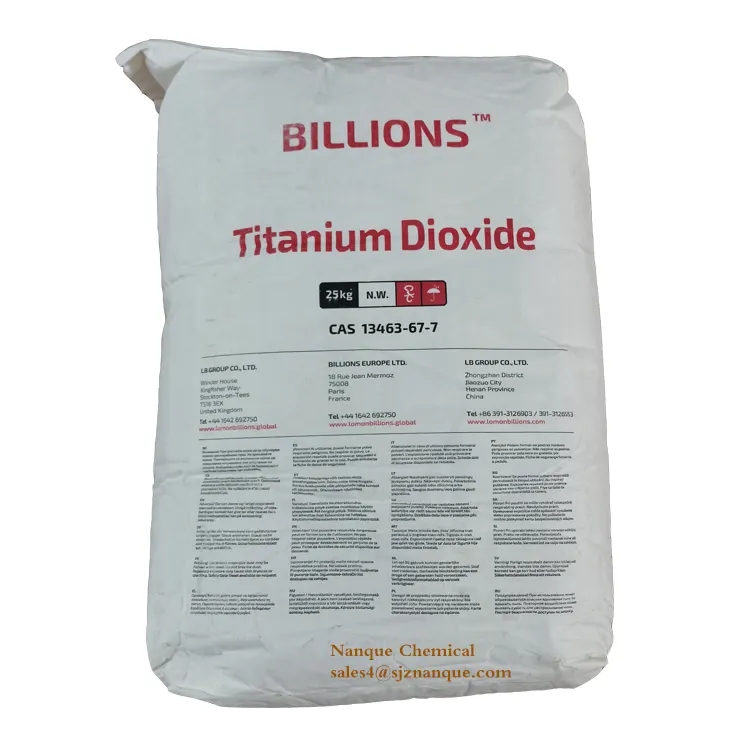

Titanium dioxide (TiO2) is one of the most widely used white pigments in various industries, renowned for its brightness, opacity, and durability. TiO2's versatility allows it to be incorporated into a myriad of products ranging from paints and coatings to plastics and cosmetics. The role of TiO2 white pigment factories is crucial in meeting the growing demand for high-quality pigment products across the globe.

The Importance of TiO2 in Various Industries

The primary function of titanium dioxide as a white pigment lies in its exceptional ability to scatter light, making it an ideal choice for creating opaque and brilliant colors. In the coatings industry, TiO2 is used in house paints, automotive finishes, and industrial coatings to enhance whiteness, brightness, and longevity. Its high refractive index helps in achieving excellent hiding power, which is essential for providing effective coverage on surfaces.

Beyond the paint industry, TiO2 plays a vital role in the plastic manufacturing sector. It is added to plastics to improve opacity and UV stability, enhancing the durability of plastic products exposed to sunlight. In the paper industry, TiO2 is utilized to improve brightness and opacity, making paper products more appealing and enhancing print quality. Additionally, TiO2 finds applications in the cosmetic industry, being a common ingredient in sunscreens, foundations, and other beauty products due to its efficacy in blocking UV rays and providing a desirable matte finish.

Manufacturing Process of TiO2 White Pigments

The production of TiO2 white pigments typically involves two primary methods the sulfate process and the chloride process. The sulfate process is a traditional method that starts with the reaction of titanium ore with sulfuric acid, producing titanium sulfate. Through a series of steps involving hydrolysis, precipitation, and calcination, TiO2 is ultimately obtained.

tio2 white pigment factory

On the other hand, the chloride process has gained popularity in recent years due to its lower environmental impact and higher purity of the final product. The chloride method begins with the reaction of titanium ore with chlorine gas, resulting in titanium tetrachloride (TiCl4) which is then oxidized to produce TiO2. The chloride process is often viewed as more efficient and cost-effective, contributing to its increasing adoption in modern TiO2 production facilities.

Challenges Faced by TiO2 Factories

Despite the growth and demand for TiO2, factories face several challenges. One major concern is the environmental impact of TiO2 production, as the manufacturing processes can generate considerable waste and emissions. Many manufacturers are investing in cleaner technologies and sustainability initiatives to reduce their carbon footprint. Additionally, stricter regulations on chemical production and emissions worldwide are pushing factories to adapt and innovate.

The market for TiO2 pigments is also susceptible to fluctuations in raw material prices and demand shifts in key industries. As various industries adapt to changing consumer preferences and technological advancements, TiO2 producers must remain agile to meet new requirements. Continuous research and development is essential for factories to innovate and introduce enhanced products that align with emerging market trends.

Future Outlook for TiO2 White Pigment Factories

As industries increasingly focus on sustainability and eco-friendly products, the future of TiO2 white pigment factories lies in their ability to innovate and adapt. The development of new technologies for more efficient production processes, combined with the incorporation of sustainable practices, will define the next generation of TiO2 manufacturing. Furthermore, as advances in nanotechnology and experiential applications emerge, the role of TiO2 could expand into new areas such as electronics and renewable energy systems.

In conclusion, TiO2 white pigment factories serve a crucial function in modern manufacturing by providing high-quality pigments that are essential across multiple sectors. While challenges exist, the commitment to innovation and sustainability will guide these factories toward a promising future. The ongoing demand for titanium dioxide paints, plastics, and cosmetics highlights not only the versatility of the material but also the vital role that TiO2 factories will continue to play in shaping industrial landscapes in the years to come.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025