Oct . 09, 2024 10:14 Back to list

tio2 used in rubber factory

Titanium Dioxide in Rubber Manufacturing Enhancing Quality and Performance

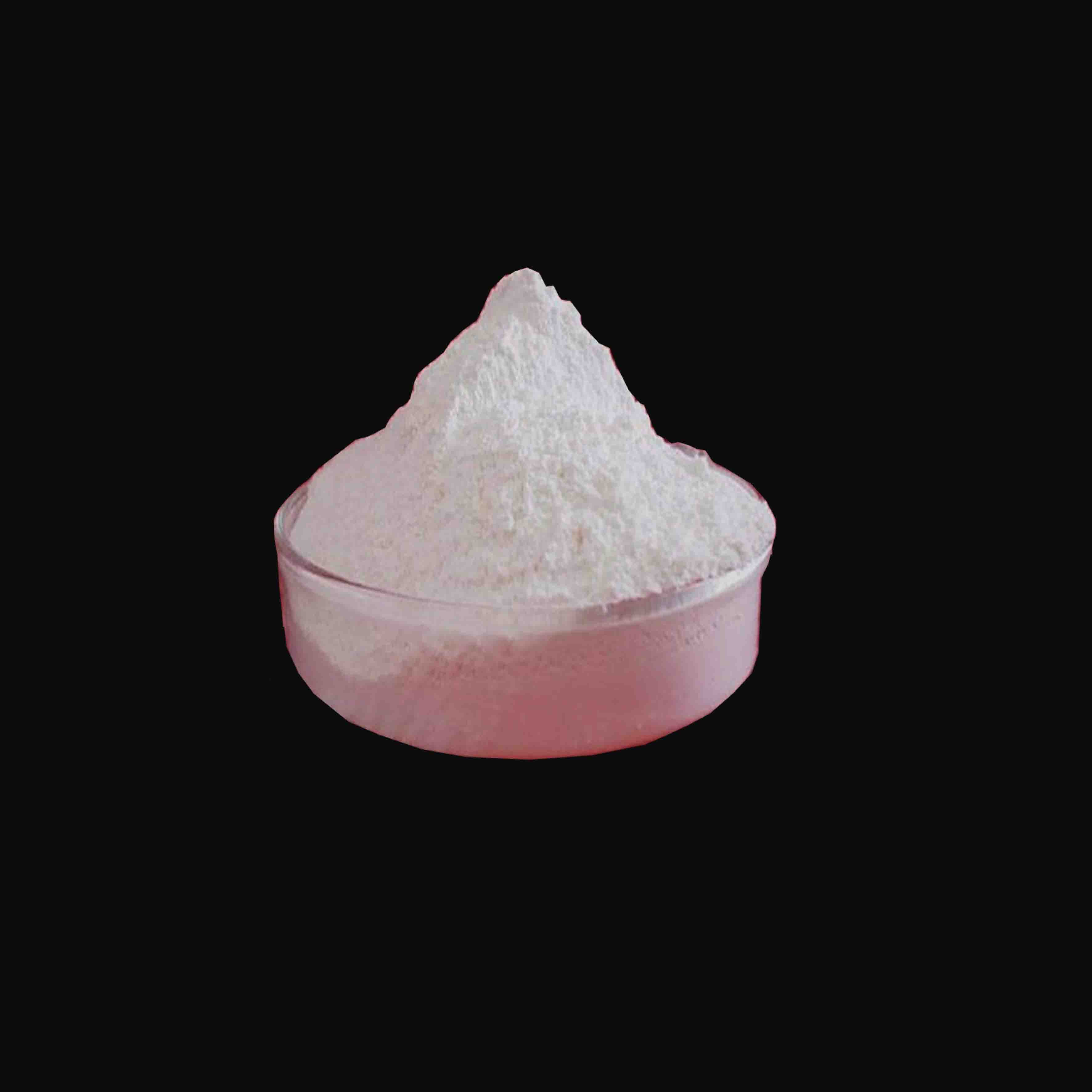

Titanium dioxide (TiO2) is a widely used white pigment in various industries, including the rubber manufacturing sector. Known for its excellent opacity, brightness, and durability, TiO2 plays a crucial role in enhancing the properties of rubber products. This article explores the significance of titanium dioxide in rubber factories, examining its benefits, applications, and environmental considerations.

The Role of Titanium Dioxide in Rubber Compounds

In the rubber industry, titanium dioxide is primarily used as a filler and pigment. Its high refractive index and scattering properties make it an ideal choice for improving the whiteness and brightness of rubber products. By incorporating TiO2, manufacturers can produce rubber with enhanced aesthetic appeal, which is particularly important for consumer-facing products, such as tires, footwear, and various rubber goods.

Additionally, TiO2 contributes to the mechanical properties of rubber. When added to rubber compounds, it improves tensile strength, tear resistance, and overall durability. This enhancement is vital for products that require high performance and longevity, such as automotive tires that must withstand various environmental conditions and stresses.

Applications of Titanium Dioxide in Rubber Products

The use of titanium dioxide in rubber manufacturing is diverse and spans multiple product categories. In tire production, TiO2 is utilized to improve the visual quality and performance of the tire rubber, leading to better grip on the road and extended lifespan. Tires with titanium dioxide also exhibit lower rolling resistance, which contributes to improved fuel efficiency in vehicles.

tio2 used in rubber factory

Beyond tires, TiO2 is commonly used in the production of seals, gaskets, and various molded rubber products. These applications benefit from the enhanced mechanical properties and visual appeal that TiO2 provides, making them more attractive to consumers and more reliable in industrial settings. The versatility of titanium dioxide enables its use in both natural and synthetic rubber compounds, catering to a wide array of applications.

Environmental Considerations

While the use of titanium dioxide in rubber manufacturing offers numerous benefits, it is essential to address potential environmental concerns associated with its production and disposal. Titanium dioxide is typically sourced from naturally occurring minerals through mining, which can have environmental implications. The extraction process may lead to habitat destruction and pollution if not managed correctly.

Moreover, concerns regarding the disposal of TiO2-containing products have prompted discussions on sustainability within the rubber industry. As awareness of environmental issues grows, manufacturers are increasingly seeking sustainable options, including recycling processes for rubber products that contain titanium dioxide. Innovations in waste management and the development of eco-friendly alternatives are vital for mitigating the environmental impact of TiO2 usage.

Future Trends

The rubber industry continues to evolve, and the role of titanium dioxide is likely to transform as well. Research into alternative, sustainable materials that can replace or reduce the reliance on traditional TiO2 is ongoing. This shift is driven by technological advancements and a growing demand for eco-conscious products. Furthermore, improvements in the processing and formulation of titanium dioxide could lead to even more efficient and high-performing rubber products.

In conclusion, titanium dioxide is an integral component of rubber manufacturing, enhancing both the quality and performance of various rubber products. Its ability to improve aesthetics, mechanical properties, and durability makes it invaluable in applications ranging from tires to industrial seals. As the industry faces environmental challenges, a renewed focus on sustainability will shape the future use of TiO2, ensuring that rubber products can meet the demands of consumers while minimizing ecological impact. As innovation continues, the rubber industry is well-positioned to adapt and thrive, leveraging the benefits of titanium dioxide responsibly.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025