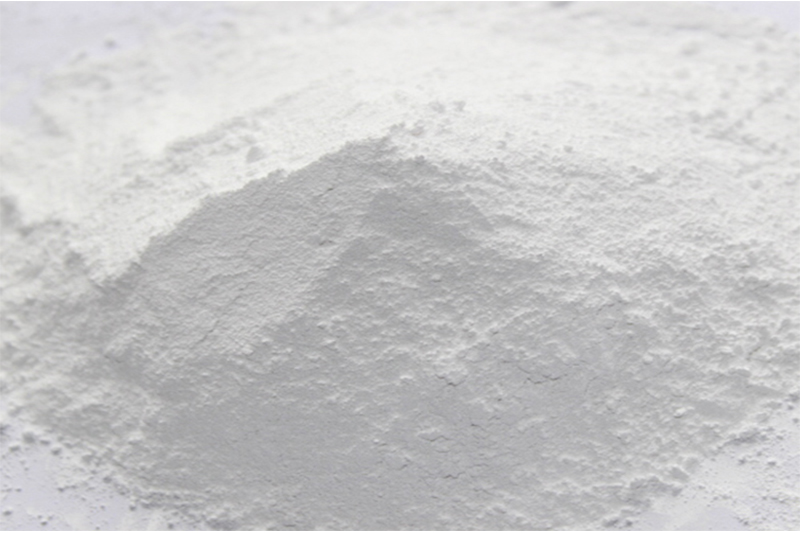

universal type product tio2 pigment titanium dioxide paints r996 manufacturer

Feb . 14, 2025 05:18 Back to list

universal type product tio2 pigment titanium dioxide paints r996 manufacturer

In the dynamic world of industrial manufacturing, Titanium Dioxide (TiO₂) in its rutile form stands as a cornerstone for various applications, ranging from paints and coatings to plastics and sunscreens. As an integral component sought after by countless industries, the choice of a reliable TiO₂ rutile type manufacturer can significantly impact the final product's quality, efficiency, and effectiveness.

Trustworthiness, another crucial factor, is deeply interwoven with transparent business practices and an unwavering commitment to customer satisfaction. Reputable manufacturers are characterized by their open communication, clarity in transactional processes, and adherence to deadlines, which collectively build a powerful foundation of trust. Testimonials and case studies from satisfied clients can serve as potent endorsements of a manufacturer's reliability and credibility. Furthermore, the environmental impact is an increasingly pivotal concern in the selection process. Manufacturers that prioritize sustainable practices—through the adoption of eco-friendly raw materials, energy-efficient processes, and comprehensive waste management systems—demonstrate a forward-thinking approach that resonates with environmentally conscious clients. This commitment not only aids in reducing their carbon footprint but also aligns with broader industry trends towards sustainability. A deep dive into the world of rutile type TiO₂ manufacturing unveils a landscape where experience and expertise converge to create authoritative and trustworthy business partnerships. As industries continue to evolve and demand more specialized solutions, the significance of choosing the right manufacturer becomes ever more pronounced. By evaluating potential partners against the refined metrics of experience, expertise, authoritative presence, and trustworthiness, businesses can ensure they join forces with a manufacturer capable of not only meeting but exceeding their expectations, thereby securing a competitive edge in their respective markets.

Trustworthiness, another crucial factor, is deeply interwoven with transparent business practices and an unwavering commitment to customer satisfaction. Reputable manufacturers are characterized by their open communication, clarity in transactional processes, and adherence to deadlines, which collectively build a powerful foundation of trust. Testimonials and case studies from satisfied clients can serve as potent endorsements of a manufacturer's reliability and credibility. Furthermore, the environmental impact is an increasingly pivotal concern in the selection process. Manufacturers that prioritize sustainable practices—through the adoption of eco-friendly raw materials, energy-efficient processes, and comprehensive waste management systems—demonstrate a forward-thinking approach that resonates with environmentally conscious clients. This commitment not only aids in reducing their carbon footprint but also aligns with broader industry trends towards sustainability. A deep dive into the world of rutile type TiO₂ manufacturing unveils a landscape where experience and expertise converge to create authoritative and trustworthy business partnerships. As industries continue to evolve and demand more specialized solutions, the significance of choosing the right manufacturer becomes ever more pronounced. By evaluating potential partners against the refined metrics of experience, expertise, authoritative presence, and trustworthiness, businesses can ensure they join forces with a manufacturer capable of not only meeting but exceeding their expectations, thereby securing a competitive edge in their respective markets.

Latest news

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025