Dec . 11, 2024 21:56 Back to list

tio2 rutile type factory

The Rise of TiO2 Rutile Type Factories A Revolution in Titanium Dioxide Production

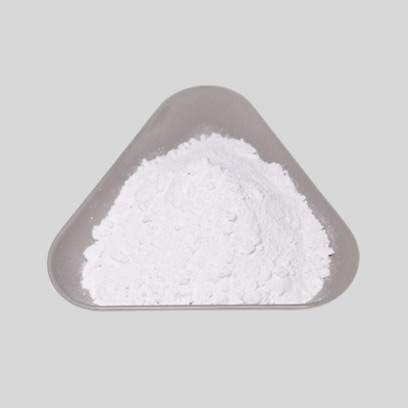

Titanium dioxide (TiO2) is one of the most widely used materials in various industries, thanks to its excellent properties, including high refractive index, excellent UV resistance, and durability. Among the different forms of titanium dioxide, rutile is particularly valued for its superior performance in applications such as coatings, plastics, and paper manufacturing. As the demand for high-quality TiO2 increases, the establishment of specialized TiO2 rutile type factories has gained momentum, marking a significant advancement in the production of this crucial compound.

Understanding Rutile

Rutile is one of the natural forms of titanium dioxide, alongside the less stable and less desirable anatase form. The rutile form is characterized by its high stability and superior opacity, which makes it ideal for applications in white pigments. It offers enhanced durability and a longer lifespan for products like outdoor paints and automotive coatings compared to its anatase counterpart. Furthermore, the ability of rutile to scatter light effectively makes it a preferred choice for applications requiring high whiteness and brightness.

The Factory Revolution

The establishment of TiO2 rutile type factories symbolizes a shift in the way titanium dioxide is produced. Traditional methods often yielded a mix of anatase and rutile, leading to inconsistent quality. However, specialized rutile factories utilize advanced techniques such as the sulfate and chloride processes to ensure the production of high-quality rutile TiO2. These methods allow for improved control over the purity and characteristics of the final product, catering to the precise needs of various industries.

1. Sulfate Process This is a widely used method for producing TiO2, where titanium-bearing ores are treated with sulfuric acid. The resulting titanyl sulfate is then hydrolyzed to produce titanium dioxide. This process is recognized for its efficiency but often requires substantial wastewater management due to the by-products generated.

2. Chloride Process In contrast, the chloride process involves converting titanium ores into titanium tetrachloride gas, which is then oxidized to produce TiO2. This method is known for its lower environmental impact and the ability to produce high-purity rutile, making it a popular choice among modern factories.

tio2 rutile type factory

Environmental Considerations

As concerns about environmental sustainability grow, TiO2 rutile type factories are increasingly implementing eco-friendly practices. Companies are now investing in technologies that minimize waste and emissions, aligning with global efforts to reduce industrial environmental footprints. Modern facilities often incorporate advanced filtration systems and recycling processes to manage hazardous materials and reduce the impact of production on local ecosystems.

Application Spectrum

The high-quality rutile TiO2 produced in these factories finds applications across various sectors. In the paint and coatings industry, it ensures excellent opacity and durability, providing a protective barrier against weather conditions. The plastics industry benefits from rutile's UV resistance, enhancing the longevity of products that are exposed to sunlight. Additionally, the paper industry utilizes rutile TiO2 to achieve high brightness and whiteness in paper products, enhancing their visual appeal and print quality.

Economic Impact

The emergence of TiO2 rutile type factories also has significant economic implications. As the global demand for high-quality titanium dioxide continues to rise, these factories create job opportunities and stimulate local economies. Additionally, the ability to produce high-purity rutile locally can lead to reduced dependency on imports, fostering economic independence in titanium dioxide supply chains.

Conclusion

In conclusion, the rise of TiO2 rutile type factories represents a pivotal moment in the production of titanium dioxide. With advancements in technology and a focus on quality and sustainability, these specialized facilities are poised to meet the growing global demand for high-performance TiO2. As industries continue to evolve, the rutile type factories will play a vital role in ensuring that the products we use daily are not only effective but also environmentally responsible. The future looks bright for this essential compound, paving the way for new innovations and applications in diverse fields.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025