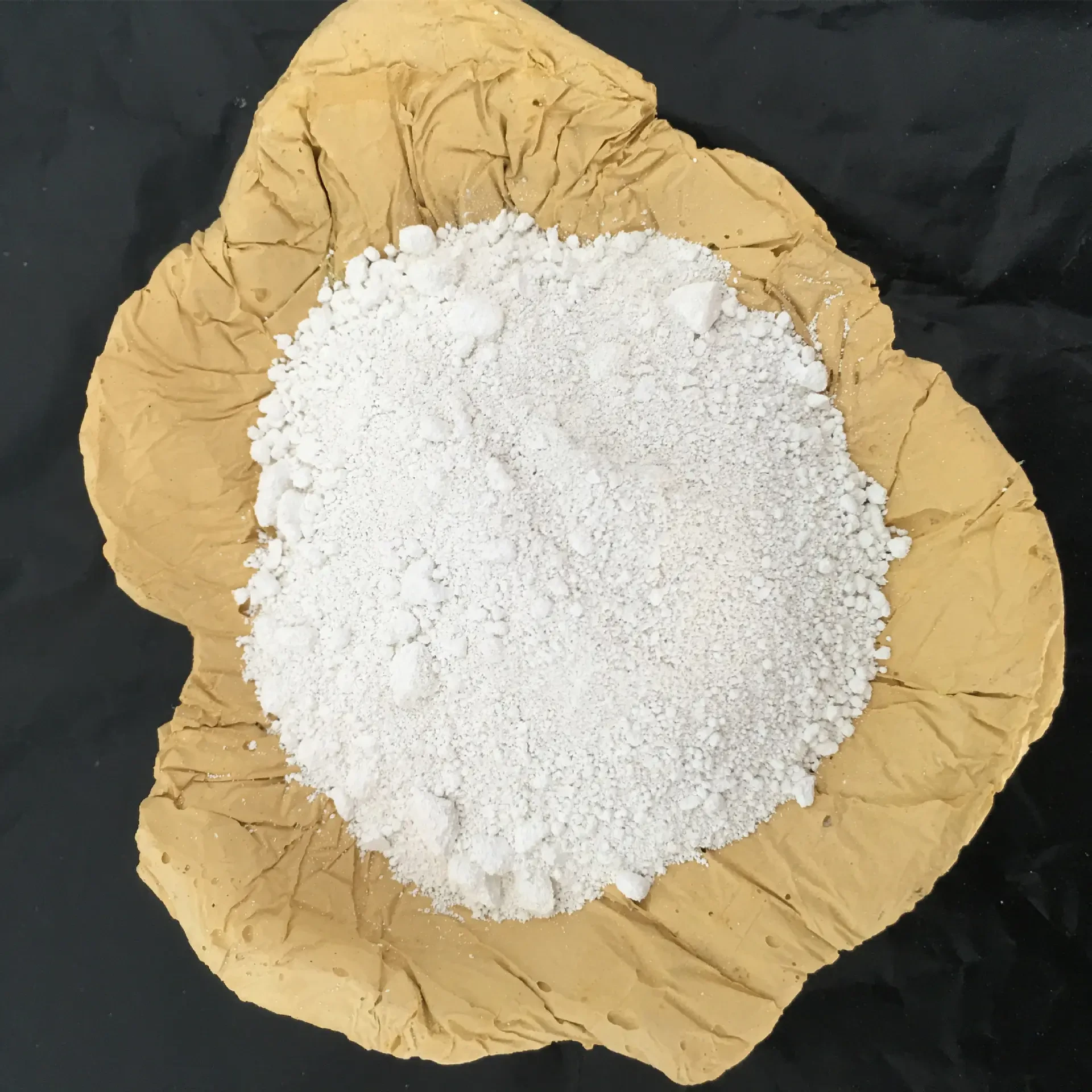

tio2 rutile powder

Feb . 11, 2025 17:09 Back to list

tio2 rutile powder

Titanium dioxide (TiO2) rutile powder is a crucial component in various industrial applications, from paint production to the manufacture of plastics and cosmetics. This versatile powder is prized for its exceptional opacity, brightness, and UV resistance, making it essential for products requiring durability and aesthetic appeal.

The manufacture of TiO2 rutile powder involves a complex process that ensures the consistency and quality of the final product. Esteemed manufacturers utilize rigorous quality control measures, from raw material selection to particle size distribution, to ensure that the powder meets specific industry standards. Advanced production techniques, including the chloride and sulfate processes, are employed to produce high-purity TiO2 with controlled particle size, contributing to its superior performance in end applications. Industry experts emphasize the importance of particle size and purity in determining the functionality of TiO2 rutile powder. Smaller particle sizes enhance the opacity while maintaining the powder's dispersibility in various mediums. Meanwhile, high purity levels ensure minimal contaminants, which could otherwise affect the performance of the end product. Building Trust through Sustainable Production Practices With growing awareness of environmental impact, many manufacturers are adopting sustainable practices in the production of TiO2 rutile powder. This includes reducing waste and emissions during manufacturing and utilizing energy-efficient processes. Consumer demand for eco-friendly products is driving innovation within the industry, leading to the development of rutile powders that align with global sustainability goals. Trustworthiness and authority in the TiO2 market are closely linked to a manufacturer's commitment to sustainability and product quality. By investing in research and development, leading producers are not only enhancing product performance but also ensuring compliance with environmental regulations. This approach not only benefits the planet but also reinforces consumer confidence in TiO2-based products. Conclusion The Future of TiO2 Rutile Powder As industries continue to evolve, the demand for high-quality TiO2 rutile powder is expected to rise. Its unparalleled properties, combined with advancements in production technology and sustainable practices, position it as a critical material across various applications. Businesses and manufacturers that prioritize quality, innovation, and sustainability in their TiO2 products are likely to remain leaders in their respective fields, offering consumers reliability and superior product performance.

The manufacture of TiO2 rutile powder involves a complex process that ensures the consistency and quality of the final product. Esteemed manufacturers utilize rigorous quality control measures, from raw material selection to particle size distribution, to ensure that the powder meets specific industry standards. Advanced production techniques, including the chloride and sulfate processes, are employed to produce high-purity TiO2 with controlled particle size, contributing to its superior performance in end applications. Industry experts emphasize the importance of particle size and purity in determining the functionality of TiO2 rutile powder. Smaller particle sizes enhance the opacity while maintaining the powder's dispersibility in various mediums. Meanwhile, high purity levels ensure minimal contaminants, which could otherwise affect the performance of the end product. Building Trust through Sustainable Production Practices With growing awareness of environmental impact, many manufacturers are adopting sustainable practices in the production of TiO2 rutile powder. This includes reducing waste and emissions during manufacturing and utilizing energy-efficient processes. Consumer demand for eco-friendly products is driving innovation within the industry, leading to the development of rutile powders that align with global sustainability goals. Trustworthiness and authority in the TiO2 market are closely linked to a manufacturer's commitment to sustainability and product quality. By investing in research and development, leading producers are not only enhancing product performance but also ensuring compliance with environmental regulations. This approach not only benefits the planet but also reinforces consumer confidence in TiO2-based products. Conclusion The Future of TiO2 Rutile Powder As industries continue to evolve, the demand for high-quality TiO2 rutile powder is expected to rise. Its unparalleled properties, combined with advancements in production technology and sustainable practices, position it as a critical material across various applications. Businesses and manufacturers that prioritize quality, innovation, and sustainability in their TiO2 products are likely to remain leaders in their respective fields, offering consumers reliability and superior product performance.

Latest news

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025