Dec . 26, 2024 02:54 Back to list

Manufacturing Processes and Innovations in Titanium Dioxide Paste Production Techniques

The TiO2 Paste Factory A Hub of Innovation and Sustainability

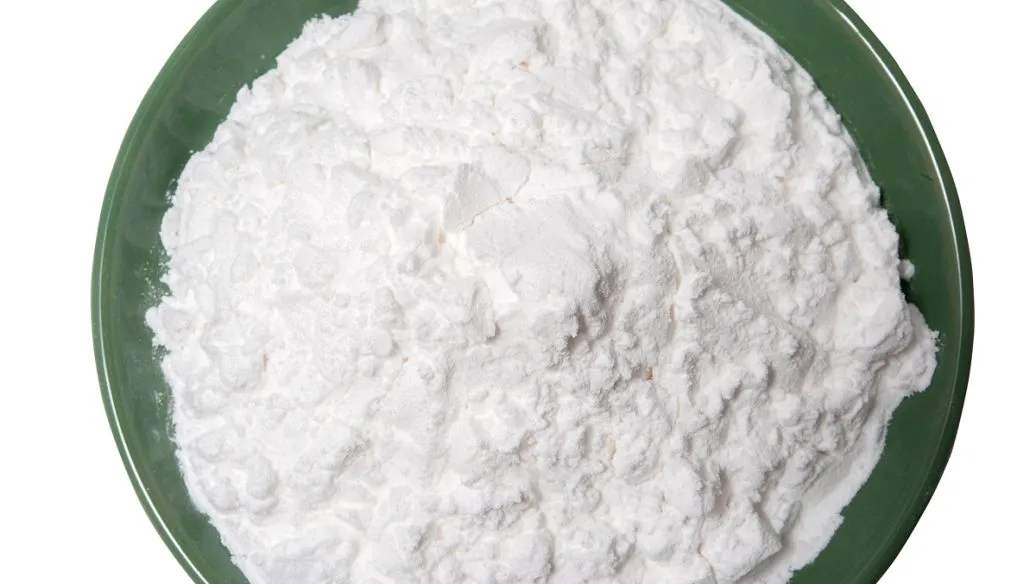

In the realm of industrial materials, titanium dioxide (TiO2) stands out for its versatility and exceptional performance. The TiO2 paste factory plays a crucial role in the production and application of this compound across various industries, including paints, coatings, plastics, and even cosmetics. As global demand for high-quality and sustainable products rises, TiO2 paste factories are evolving to meet these challenges while emphasizing innovation and eco-friendliness.

Understanding Titanium Dioxide

Titanium dioxide is a naturally occurring oxide of titanium, known for its high refractive index and strong UV-light absorbing capabilities. It has become an indispensable ingredient in many products due to its brightness and durability. In the paint industry, for instance, TiO2 is valued for its ability to provide excellent opacity and color stability. As consumers increasingly seek long-lasting and environmentally sustainable products, the demand for TiO2 is expected to grow, prompting manufacturers to enhance production processes and formulations.

The Production Process

The production of TiO2 paste involves several steps to ensure consistent quality and performance. Initially, titanium ore is sourced and processed through processes such as the sulfate and chloride methods. The sulfate process involves digesting the ore in sulfuric acid, while the chloride process utilizes chlorine to produce a purer form of TiO2. Once the TiO2 is obtained, it is processed into a paste, which involves mixing it with various additives to achieve desired properties such as viscosity, stability, and compatibility with other materials.

This paste formulation is critical as it must meet the specific needs of different applications. Factors such as environmental conditions, substrate materials, and end-use characteristics must be taken into account. Consequently, research and development teams within TiO2 paste factories continuously evaluate and test new formulations to improve performance and meet regulatory standards.

Environmental Considerations

tio2 paste factory

Sustainability is a pivotal concern in today’s manufacturing landscape. As the implications of climate change and resource depletion become more pronounced, TiO2 paste factories are adopting greener practices. This includes the use of more sustainable raw materials, energy-efficient production processes, and waste minimization techniques.

Moreover, several factories are exploring the development of TiO2 products that are less harmful to the environment. For example, formulations that reduce volatile organic compound (VOC) emissions in paints and coatings are gaining popularity. By prioritizing eco-friendly practices, TiO2 paste factories not only comply with regulations but also appeal to environmentally conscious consumers and businesses.

Innovation and Technology

Technological advancements are transforming the operations of TiO2 paste factories. Automation and digitalization play significant roles in enhancing the efficiency of production processes. Advanced manufacturing techniques, such as 3D printing and nanotechnology, are being explored to create novel TiO2 applications that were not feasible before.

Furthermore, collaborative research initiatives between academia and industry are paving the way for innovative uses of TiO2. For instance, its potential in photocatalysis for environmental remediation and self-cleaning coatings is being researched extensively. These innovative applications not only highlight the multifunctionality of TiO2 but also reinforce the idea that TiO2 paste factories are at the forefront of material science.

Conclusion

The TiO2 paste factory is a vital player in the material production landscape, marrying traditional manufacturing techniques with modern demands for sustainability and innovation. As industries continue to evolve and prioritize environmentally friendly practices, TiO2 paste factories are positioned to lead the charge. They not only provide essential materials for a wide variety of applications but also contribute to the global effort of creating a more sustainable future. As we look ahead, the continued advancement in TiO2 technologies promises exciting opportunities and developments that will impact various sectors, from construction to consumer goods, ultimately benefiting society as a whole.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025