Nov . 20, 2024 06:45 Back to list

tio2 cost

TiO2 Cost An In-Depth Analysis of Factors Affecting Price and Market Trends

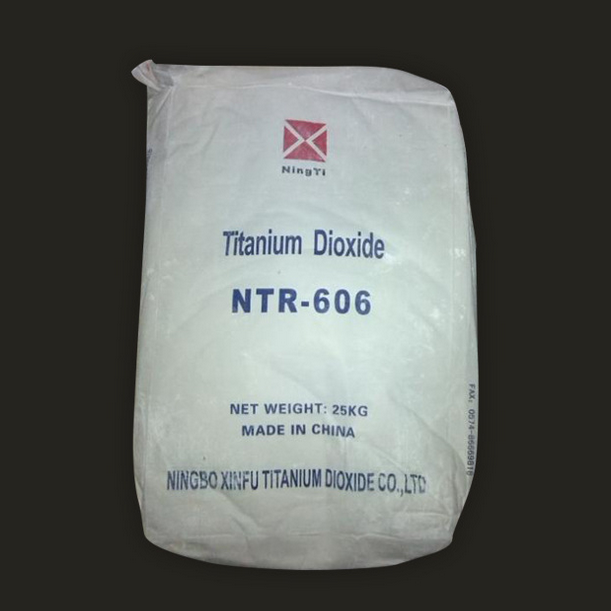

Titanium dioxide (TiO2) is a white pigment widely used in various industries, including paints, coatings, plastics, and paper. It is renowned for its excellent opacity, brightness, and durability. As demand for high-quality TiO2 continues to grow, it's essential to understand the factors influencing its cost and the current market trends.

Production Processes and Costs

The production of TiO2 primarily occurs through two methods the sulfate process and the chloride process. Each method has distinct implications for production costs.

1. Sulfate Process This traditional method involves the reaction of titanium ores (such as ilmenite) with sulfuric acid. The sulfate process typically requires significant energy inputs and generates large amounts of waste, impacting both environmental considerations and production costs. The complexity and low yield of by-products can lead to higher overall production expenses.

2. Chloride Process This more modern method uses titanium tetrachloride (TiCl4) as an intermediate. It is generally considered more efficient and environmentally friendly compared to the sulfate process. However, the initial capital investment for chlorination equipment and the requirement for high-purity titanium feedstock can result in higher costs. Despite this, the chloride process produces a superior grade of TiO2 with higher brightness, which can justify the investment in quality.

Raw Material Costs

The cost of raw materials plays a significant role in determining the price of TiO2. Ilmenite (FeTiO3) and rutile (TiO2) are the primary sources for TiO2 production. Price fluctuations for these minerals directly affect the overall manufacturing cost. For instance, increases in mining costs, transportation expenses, or geopolitical issues in major producing countries can lead to higher TiO2 prices.

Additionally, the availability of high-quality feedstock can influence production efficiency and costs. As high-grade ores become scarcer, manufacturers may need to invest in more complex extraction and refining techniques, further increasing costs.

Energy Prices

Energy consumption is another critical factor in TiO2 production. Both the sulfate and chloride processes are energy-intensive, meaning that fluctuations in energy prices can have a significant impact on production costs. With a global shift towards renewable energy and fluctuations in fossil fuel costs, manufacturers must adapt their strategies to manage energy expenses effectively.

tio2 cost

Environmental Regulations

Environmental concerns are becoming increasingly important in the production process of many industrial chemicals and materials, including TiO2. Stricter regulations regarding emissions and waste disposal require manufacturers to invest in cleaner technologies and sustainable practices. Compliance with these regulations can elevate production costs, which may ultimately be passed on to consumers.

Market Demand

The demand for TiO2 is influenced by several key factors

1. Construction and Infrastructure Strong demand from the construction sector, particularly in emerging markets, drives TiO2 consumption as it is pivotal in paints and coatings. 2. Automotive Industry The automotive sector's push for high-quality coatings and finishes also contributes to TiO2 demand. As vehicle manufacturers focus on aesthetics and durability, the demand for premium-grade TiO2 is likely to rise.

3. Technological Advancements Innovations in product formulations and applications – such as more efficient coatings and the use of TiO2 in the production of plastics and electronics – can lead to increased demand.

Future Prospects

As the global economy recovers post-pandemic, the demand for TiO2 is expected to rise, potentially leading to a tight supply situation. This could drive prices up further as manufacturers struggle to keep pace with rapidly increasing demand.

Additionally, the push towards sustainability is likely to reshape the TiO2 market. Investment in greener production methods and alternative raw materials may provide new pathways to mitigate costs and address environmental concerns. Innovations in recycling and the development of bio-based TiO2 materials could also influence future pricing dynamics.

Conclusion

In summary, the cost of TiO2 is influenced by a multitude of factors, including production methods, raw material availability, energy prices, environmental regulations, and market demand. As the industry navigates these challenges, understanding the underlying dynamics of the TiO2 market will be essential for stakeholders, from producers to end-users. Keeping an eye on technological innovations and shifts in global demand will be crucial for anticipating future trends in TiO2 pricing.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025