Oct . 06, 2024 08:30 Back to list

tio2 chemical factory

The TiO2 Chemical Factory Pioneering Innovation and Sustainability

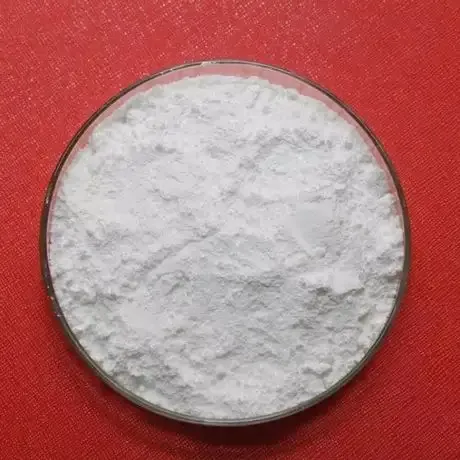

Titanium dioxide (TiO2) is a versatile and essential chemical used in various applications, including paints, coatings, plastics, paper, and even cosmetics. As the demand for TiO2 continues to rise globally, the significance of TiO2 chemical factories has become increasingly pronounced. These factories not only play a pivotal role in the production of this important compound but also leverage innovative practices to enhance sustainability and meet the environmental challenges of our time.

At the heart of a TiO2 chemical factory is a sophisticated production process that converts titanium ore into pure titanium dioxide. The two primary methods of production are the sulfate process and the chloride process. The sulfate process involves digesting titanium ore, such as ilmenite, with sulfuric acid, creating a titanium sulfate solution. This is then subjected to precipitation to yield TiO2. The chloride process, on the other hand, involves reacting titanium ore with chlorine to produce titanium tetrachloride, which is subsequently oxidized to form TiO2. While both processes can produce high-quality titanium dioxide, the chloride process is generally recognized for its environmental advantages, including lower emissions and less waste generation.

The TiO2 Chemical Factory Pioneering Innovation and Sustainability

Moreover, waste management is a crucial aspect of TiO2 production. Factories are increasingly seeking ways to recycle waste materials generated during the manufacturing process. Initiatives such as converting solid waste into reusable raw materials or employing advanced treatment systems to reclaim water have become standard practices. By adopting a circular economy approach, TiO2 chemical manufacturers can reduce their ecological footprint and contribute to long-term sustainability.

tio2 chemical factory

Another significant development in TiO2 manufacturing is the advent of nanotechnology. Research and innovation in this field have led to the creation of nano-TiO2, which has unique properties that enhance its applications in various industries. Nano-TiO2 is not only effective as a photocatalyst but also provides superior performance in sunscreens and self-cleaning surfaces. As the demand for nano-TiO2 continues to grow, chemical factories are adapting their processes to accommodate the production of this advanced material while ensuring safety and environmental protection.

The TiO2 industry is also witnessing a shift towards digitalization and automation. By integrating advanced data analytics and artificial intelligence into their processes, factories can optimize operations, reduce energy consumption, and minimize waste generation. Smart manufacturing practices enable real-time monitoring and control, leading to improved efficiency and product quality.

Moreover, collaboration plays a vital role in the advancement of TiO2 manufacturing. Chemical factories are increasingly partnering with research institutions, government agencies, and environmental organizations to accelerate innovation while adhering to best practices in sustainability. These collaborations foster knowledge exchange and drive the development of new technologies that can revolutionize the industry.

In conclusion, TiO2 chemical factories are at the forefront of producing one of the most widely used chemicals in the world. As they navigate the challenges posed by environmental concerns and changing market demands, these factories are embracing innovation and sustainability in their operations. Through advanced production techniques, waste management strategies, the application of nanotechnology, and digital transformation, TiO2 chemical factories are not only enhancing their competitiveness but also contributing positively to the environment and society as a whole. The future of TiO2 production looks promising, driven by a commitment to sustainability and innovation.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025