Dec . 11, 2024 10:21 Back to list

Titanium Dioxide Production Facility Overview and Process Insights

The Importance of TiO2 Chemical Factories in Modern Industry

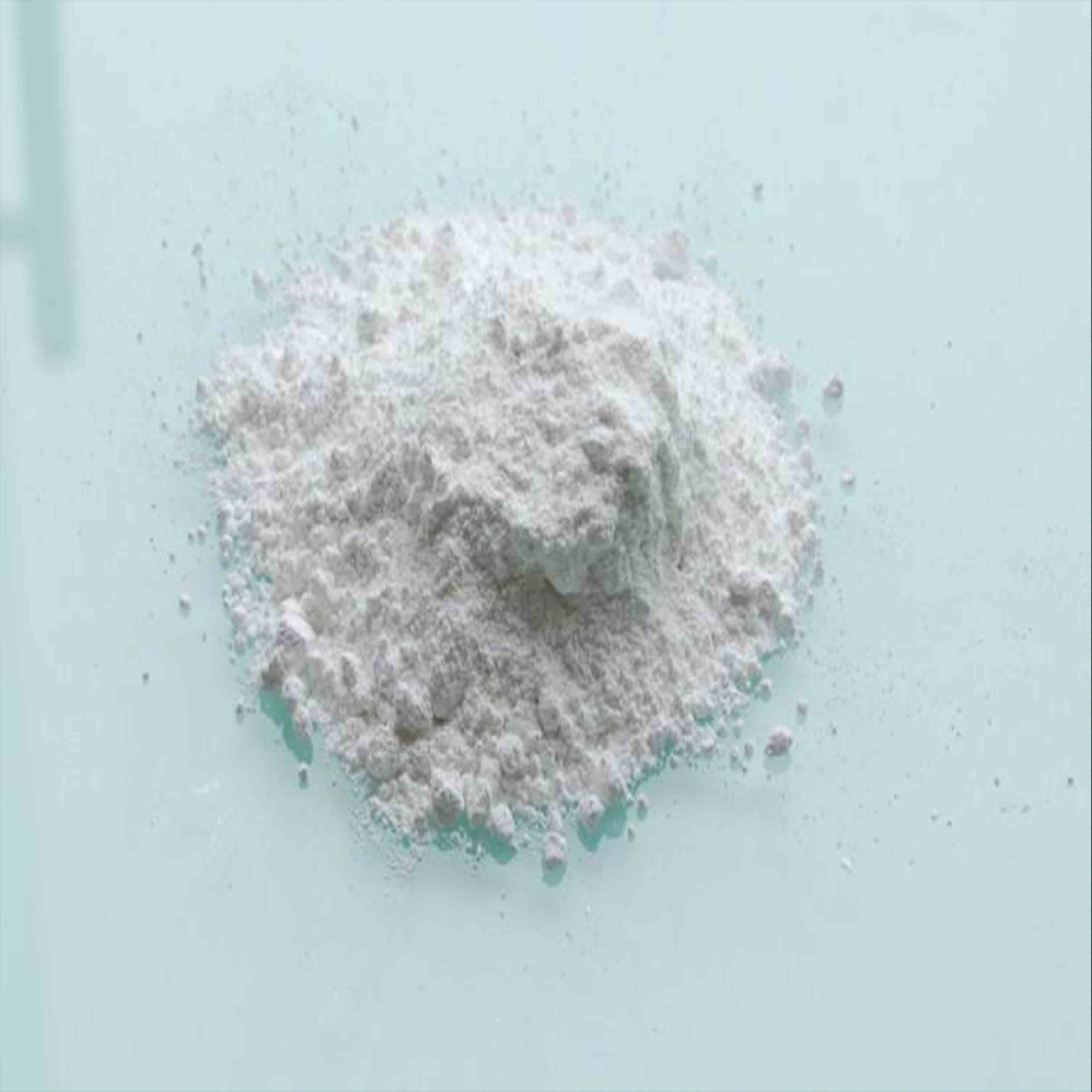

Titanium dioxide, commonly referred to as TiO2, is a widely used inorganic compound renowned for its excellent opacity, brightness, and durability. This versatile material is found in a diverse array of applications, ranging from paint and coatings to plastics and cosmetics. As the demand for TiO2 continues to rise, the role of TiO2 chemical factories becomes increasingly significant in meeting industrial needs while adhering to environmental standards and sustainability.

The Manufacturing Process of TiO2

TiO2 is primarily produced through two main processes the sulfate process and the chloride process. The sulfate process, which involves the reaction of titanium ore with sulfuric acid, is known for producing high-grade titanium dioxide. However, it generates large volumes of waste, which poses environmental challenges. On the other hand, the chloride process, which uses titanium ore and chlorine gas, tends to be more efficient and environmentally friendly, leading to a purer final product with fewer pollutants.

Both processes require carefully controlled conditions and sophisticated technology to ensure the consistent quality of TiO2. Chemical factories that specialize in TiO2 production invest heavily in advanced machinery and monitoring systems to optimize these processes. This ensures that the produced TiO2 conforms to the stringent specifications required by various downstream industries.

Applications of Titanium Dioxide

The applications of TiO2 are vast and varied. One of the largest sectors utilizing TiO2 is the paint and coatings industry. It serves as a pigment that enhances opacity and brightness, allowing for high-quality finishes in everything from house paints to industrial coatings. TiO2’s ability to withstand ultraviolet (UV) radiation makes it particularly valuable in outdoor applications, protecting surfaces from degradation and discoloration.

tio2 chemical factory

In the plastics industry, TiO2 acts as a filler and a UV stabilizer, enhancing the properties of products like packaging materials and automotive parts. The cosmetics industry also benefits from TiO2 due to its opacity, which is used in sunscreens, face powders, and creams, providing coverage and protection from UV rays.

Additionally, TiO2 has applications in the production of ceramics, rubber, and even food products, showcasing its versatility across different domains. With the ongoing trend towards sustainability, TiO2 is also being explored in photocatalytic applications, such as air and water purification, which could have significant implications for environmental protection.

Environmental Considerations

While TiO2 production is vital for numerous industries, it is not without its environmental challenges. Traditional manufacturing processes can lead to the release of harmful substances, including waste products that require careful management. As a response to these concerns, many TiO2 chemical factories are actively adopting greener technologies and practices.

Investments in waste recycling and treatment systems are becoming common in the industry. Some factories are exploring the use of alternative raw materials and innovative production methods that reduce the environmental impact. By implementing these sustainable practices, TiO2 manufacturers are not only adhering to regulatory requirements but also contributing to the global movement toward more sustainable industrial processes.

Conclusion

In conclusion, TiO2 chemical factories play a crucial role in providing an essential material that is integral to various industries. As the demand for high-quality titanium dioxide continues to grow, it is imperative for manufacturers to balance production needs with environmental considerations. The ongoing innovation in processing techniques and commitment to sustainability will determine the future trajectory of TiO2 production. Ultimately, by embracing greener practices, TiO2 chemical factories can ensure that they remain a vital component of modern industrial ecosystems while safeguarding the environment for future generations.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025