Sep . 10, 2024 18:09 Back to list

ti02 powder manufacturer

The Role of TiO2 Powder Manufacturers in Various Industries

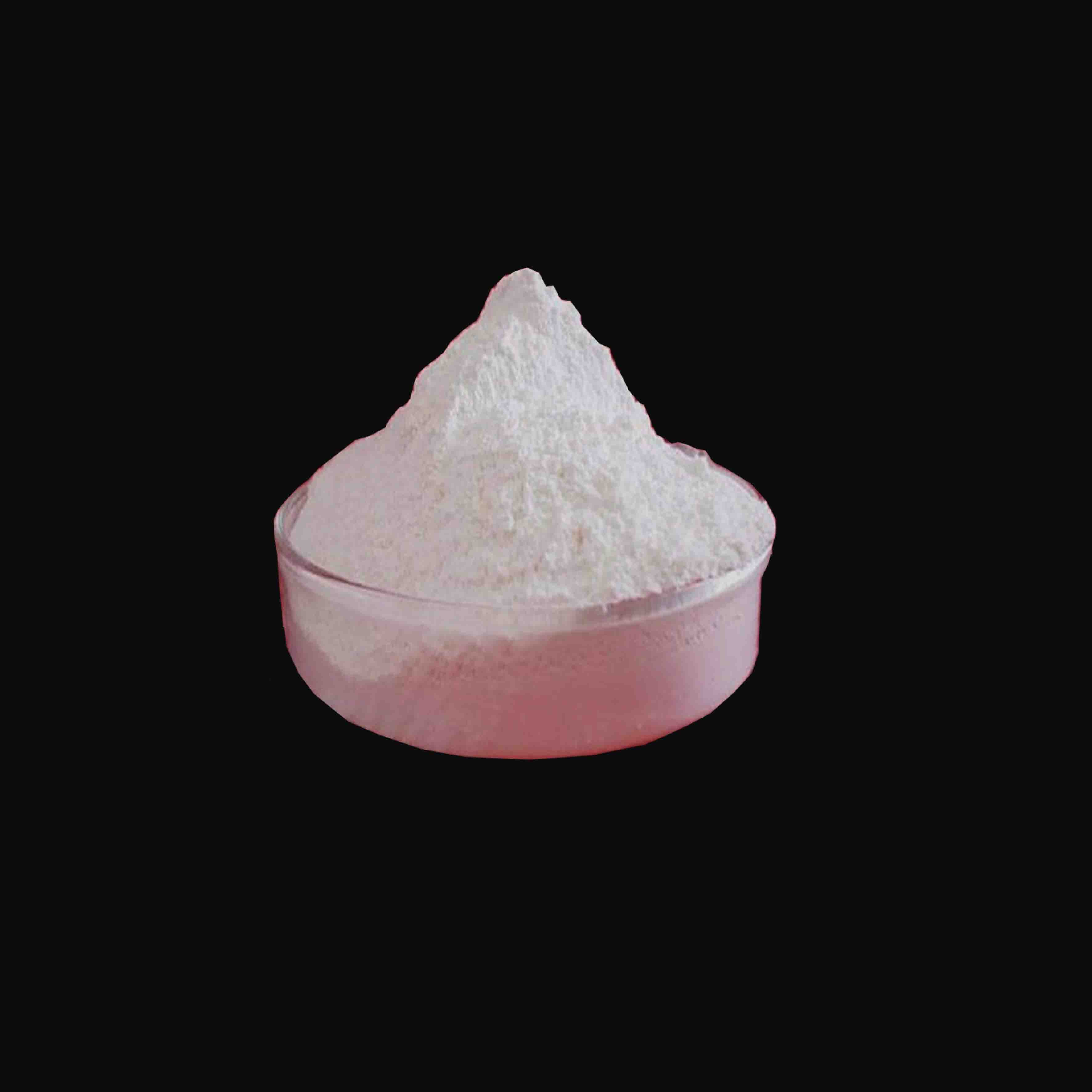

Titanium dioxide (TiO2) is a versatile compound widely used across multiple industries due to its exceptional properties, such as brightness, opacity, and UV resistance. As a result, TiO2 powder manufacturers play a crucial role in the supply chain of products ranging from coatings to plastics and even food. Understanding the production and application of TiO2 powder is essential for businesses and consumers alike.

Manufacturing Process of TiO2 Powder

The manufacturing of TiO2 powder generally involves two main processes the sulfate process and the chloride process. The sulfate process uses sulfuric acid to extract titanium dioxide from titanium-containing minerals. This method is highly effective but can generate substantial waste, raising environmental concerns. On the other hand, the chloride process offers a cleaner alternative, using chlorine to convert titanium minerals into titanium tetrachloride, which is then oxidized to produce high-purity TiO2. This process tends to be more efficient and less polluting, making it increasingly popular among manufacturers.

Applications of TiO2 Powder

1. Paints and Coatings One of the primary applications of TiO2 powder is in the paint and coatings industry. Its high refractive index and excellent covering power make it an ideal pigment for producing bright and durable paints. TiO2 enhances the longevity and weather resistance of coatings, making it invaluable for both interior and exterior applications.

ti02 powder manufacturer

2. Plastics TiO2 powder is often added to plastic products to improve their opacity and brightness. It not only enhances the aesthetic qualities of the plastic but also helps protect it from UV degradation, leading to longer-lasting products. From everyday items like toys to automotive parts, TiO2 has become an indispensable additive.

3. Cosmetics In the cosmetics industry, TiO2 powder is used as a pigment in various products, including sunscreens, face powders, and foundations. Its ability to provide UV protection makes it a popular choice for formulations that aim to protect the skin from sun damage. Moreover, TiO2's smooth texture contributes to the appealing consistency of cosmetics.

4. Food Industry Surprisingly, TiO2 is also used in the food industry as a whitening agent. Certain food products, including candies and dairy items, incorporate TiO2 to achieve a brighter appearance. However, the use of TiO2 in food has raised health concerns, leading to regulations in various countries. Manufacturers must be careful to comply with these regulations while maintaining product quality.

5. Photocatalysis TiO2 powder is gaining attention in environmental applications, especially in photocatalysis, where it is used for breaking down pollutants in air and water. This property makes TiO2 a promising candidate for developing green technologies aimed at improving air quality and wastewater treatment.

Conclusion

TiO2 powder manufacturers occupy a pivotal position in the production chain that supports various sectors, from construction to beauty. As industries increasingly prioritize sustainability and eco-friendliness, manufacturers are likely to explore innovative processes and applications for TiO2 that minimize environmental impact while maximizing efficiency. Staying informed about advancements in TiO2 production and application can benefit businesses and consumers, ensuring that they harness the full potential of this remarkable compound.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025