Dec . 05, 2024 08:37 Back to list

Production of Talc and Titanium Dioxide in Modern Manufacturing Facilities

The Importance of Talc and Titanium Dioxide in Industrial Applications

Talc and titanium dioxide are two significant materials widely used across various industries. Their unique properties and versatile applications make them indispensable in manufacturing and production processes. This article explores the characteristics, uses, and benefits of talc and titanium dioxide, as well as the operational aspects of factories producing these materials.

Talc A Multifaceted Mineral

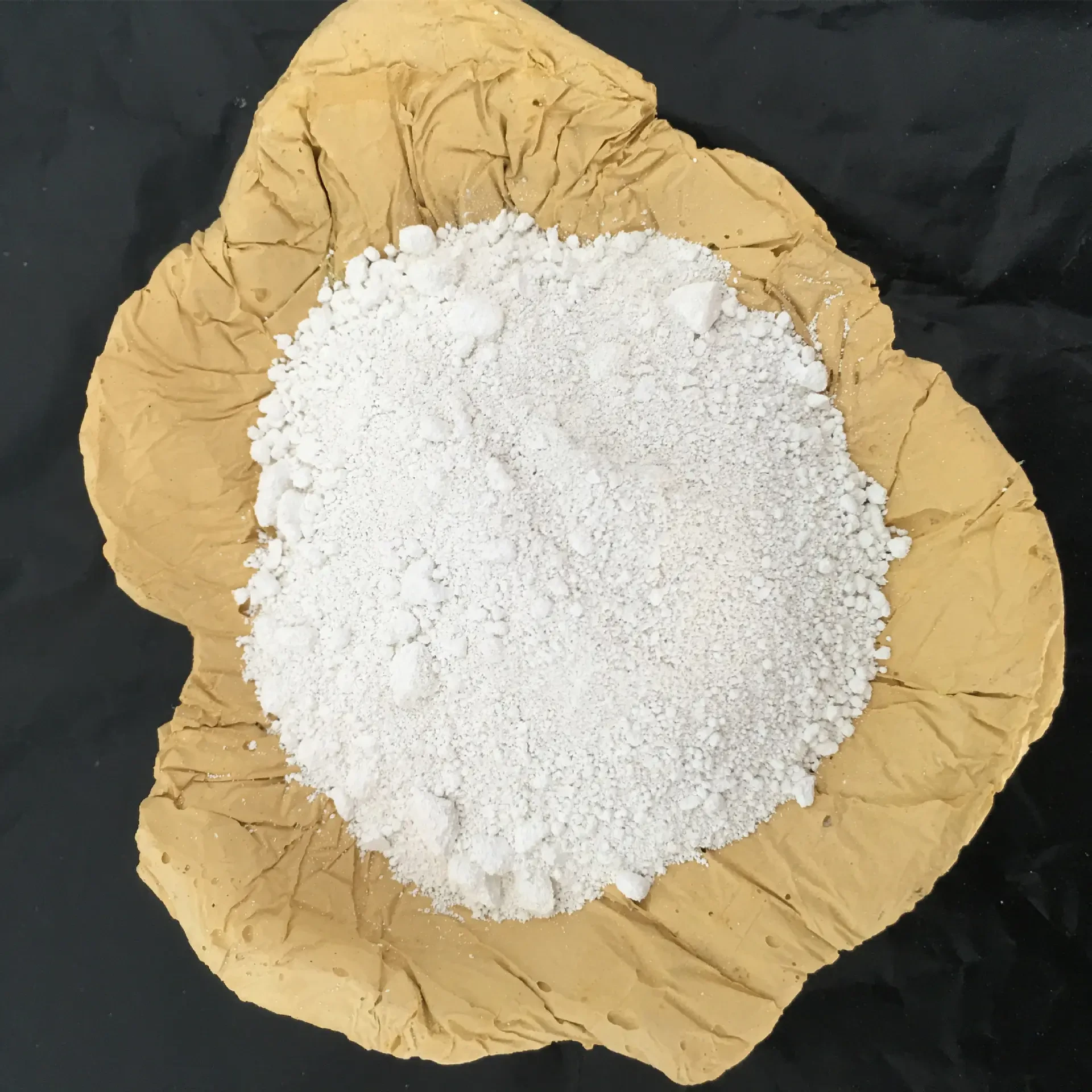

Talc is a naturally occurring mineral composed primarily of magnesium, silicon, and oxygen. Known for its softness, it is the softest mineral on the Mohs scale. This characteristic allows talc to be used in numerous applications. In the cosmetic industry, talc is a key ingredient in body powders, face powders, and other makeup products due to its ability to absorb moisture and provide a silky texture.

Moreover, talc finds significant applications in plastics, ceramics, paper, and rubber manufacturing. Producers of these materials rely on the mineral's properties to enhance product performance. For instance, in the plastic industry, talc is used as a filler to improve impact resistance and reduce production costs. In ceramics, it helps in lowering the firing temperature, thus optimizing energy use during production.

Titanium Dioxide The Ultimate Pigment

Titanium dioxide (TiO2) is a white pigment frequently used in paint, coatings, plastics, and food products. It is renowned for its brightness and high refractive index, making it the preferred choice for achieving opacity and durability in various applications. Paint manufacturers prize titanium dioxide for its ability to enhance brightness and provide a long-lasting finish.

talc and titanium dioxide factory

In the field of cosmetics, titanium dioxide serves as a physical sunscreen agent, reflecting harmful UV rays. Its safety and effectiveness have resulted in its widespread adoption in skincare products. Additionally, titanium dioxide is used in photocatalytic applications, where it helps in breaking down pollutants under UV light, contributing to environmental sustainability.

Factories Producing Talc and Titanium Dioxide

Factories specializing in the production of talc and titanium dioxide employ advanced extraction and processing techniques to ensure high-quality products. The mining of talc typically involves a combination of open-pit and underground mining methods. Once extracted, the mineral undergoes milling, which involves crushing and grinding to achieve the desired particle size and purity.

On the other hand, titanium dioxide is produced primarily through two processes the sulfate process and the chloride process. The sulfate process involves the reaction of titanium ore with sulfuric acid, while the chloride process uses chlorine to extract pure titanium dioxide.

Both processes require strict adherence to safety and environmental regulations due to the chemicals involved and the potential impact on the surrounding ecosystem. Modern factories employ state-of-the-art technology to minimize waste and emissions, ensuring sustainability and safety throughout the production cycle.

Conclusion

Talc and titanium dioxide are vital components that play significant roles in various industries. From cosmetics to construction materials, these minerals enhance product quality and performance. As manufacturing processes evolve, the demand for high-quality talc and titanium dioxide continues to grow, prompting factories to adopt innovative techniques and sustainable practices. The future of these materials looks promising, marking an ongoing journey of exploration and application across multiple sectors. As industries strive for better quality and eco-friendly options, the relevance of talc and titanium dioxide will only increase, reinforcing their status as indispensable minerals in the global market.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025