Nov . 17, 2024 08:57 Back to list

synthetic titanium dioxide manufacturers

The Rise of Synthetic Titanium Dioxide Manufacturers

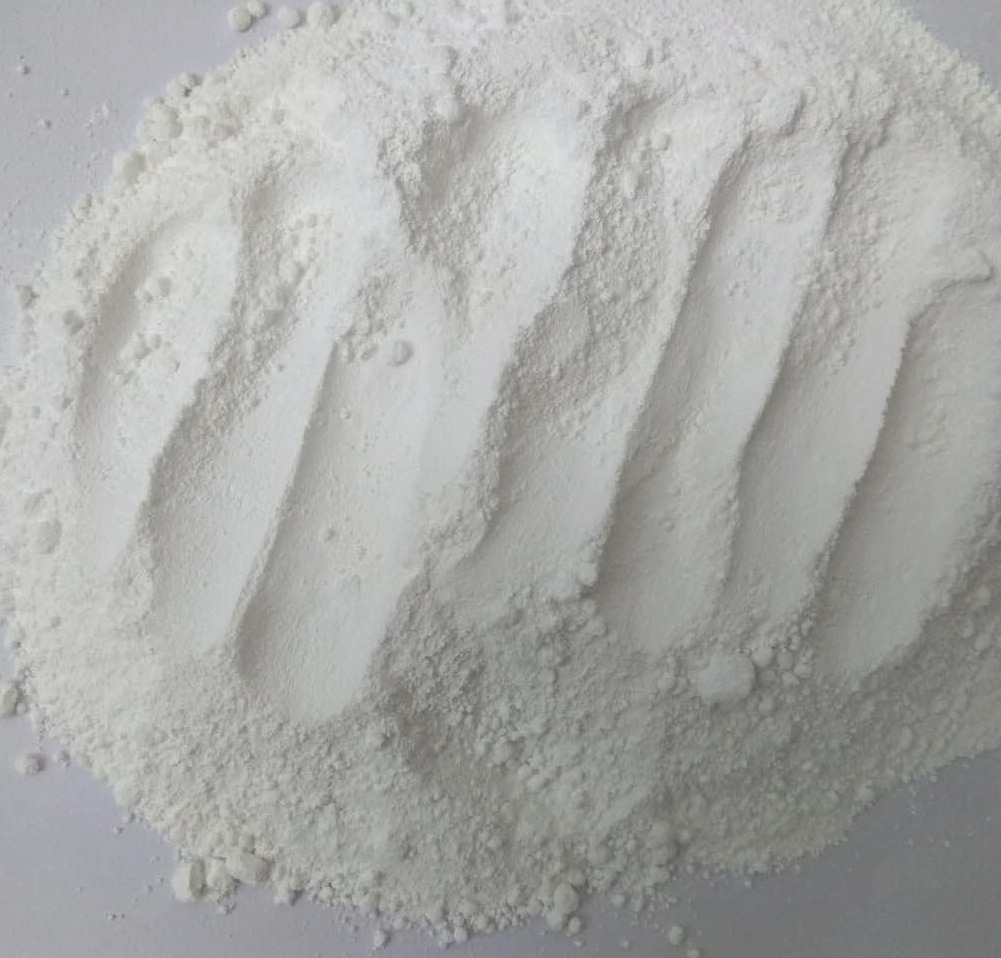

In recent years, the global demand for synthetic titanium dioxide (TiO2) has surged due to its diverse applications across various industries. This white inorganic pigment, known for its exceptional brightness and opacity, is predominantly used in coatings, plastics, paper, and cosmetics. As environmental awareness increases and regulations concerning the use of certain materials tighten, the prominence of synthetic titanium dioxide manufacturers has grown significantly.

Understanding Synthetic Titanium Dioxide

Synthetic titanium dioxide is produced through a variety of processes, with the sulfate and chloride methods being the most common. The sulfate process involves the reaction of ilmenite ore with sulfuric acid, while the chloride process uses titanium tetrachloride as a precursor. Both processes yield high-purity TiO2, which is essential for its performance in high-end applications. Synthetic titanium dioxide is favored over its natural counterpart because of its superior quality and consistency.

Market Dynamics

The synthetic titanium dioxide market is experiencing notable growth driven by several factors. First, the expansion of end-use industries, particularly automotive and construction, directly influences the demand for high-performance coatings that require titanium dioxide for durability and UV protection. According to industry reports, the global titanium dioxide market is expected to witness a compound annual growth rate (CAGR) of around 4% over the next few years, underscoring the growing applicability of this versatile compound.

Furthermore, the cosmetic industry has embraced synthetic titanium dioxide, utilizing it in sunscreens and makeup products due to its ability to provide sun protection and enhance product texture. As consumers increasingly seek products that offer not only aesthetic appeal but also safety and efficacy, the demand for synthetic TiO2 in cosmetics is anticipated to rise.

Environmental Considerations

With the rise in popularity of synthetic titanium dioxide comes the responsibility of manufacturers to address environmental concerns associated with its production. Traditional methods of TiO2 production have been criticized for their environmental impact, particularly in terms of waste generation and emissions. In response, manufacturers are investing in more sustainable practices, such as recycling processes and waste minimization techniques, to reduce their carbon footprint and comply with stricter regulations.

synthetic titanium dioxide manufacturers

Many synthetic titanium dioxide manufacturers are now adopting a circular economy approach, which emphasizes reusing resources and minimizing waste. For instance, some companies recycle the by-products from the titanium dioxide manufacturing process, converting them into valuable materials for other industries. This not only boosts sustainability but also reduces production costs, thus enhancing the competitive edge of these manufacturers in the market.

The Competitive Landscape

The market for synthetic titanium dioxide is characterized by a range of players, from multinational corporations to specialized manufacturers. Leading companies such as Chemours, Tronox, and Huntsman are notable for their extensive research and development efforts, enabling them to innovate and capture a substantial market share. These companies are continually exploring advanced technologies to enhance product performance and reduce production costs.

Additionally, smaller manufacturers are emerging, focusing on niche markets and catering to specific customer needs. This diversification has created a competitive landscape that encourages innovation and efficiency among synthetic titanium dioxide producers.

Future Prospects

Looking ahead, the future of synthetic titanium dioxide manufacturers appears bright. As industries evolve and consumer preferences shift towards more sustainable products, the demand for high-quality synthetic TiO2 is likely to persist. Additionally, advancements in technology are paving the way for more efficient production methods that reduce environmental impacts while improving product quality.

Investments in research and development will play a crucial role in shaping the future of this industry. Manufacturers that prioritize innovation and sustainability are poised to lead the market as they adapt to changing regulations and consumer demands.

In conclusion, synthetic titanium dioxide manufacturers are at the forefront of a growing industry that balances product quality with environmental responsibility. With increasing applications in various sectors and a commitment to sustainable practices, they are well-positioned to meet the demands of the modern marketplace, paving the way for a brighter and more sustainable future.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025