Aug . 06, 2024 08:12 Back to list

Safety Data and Compliance Information for Lithopone Manufacturing and Usage Guidelines

Understanding Lithopone MSDS and Industrial Applications

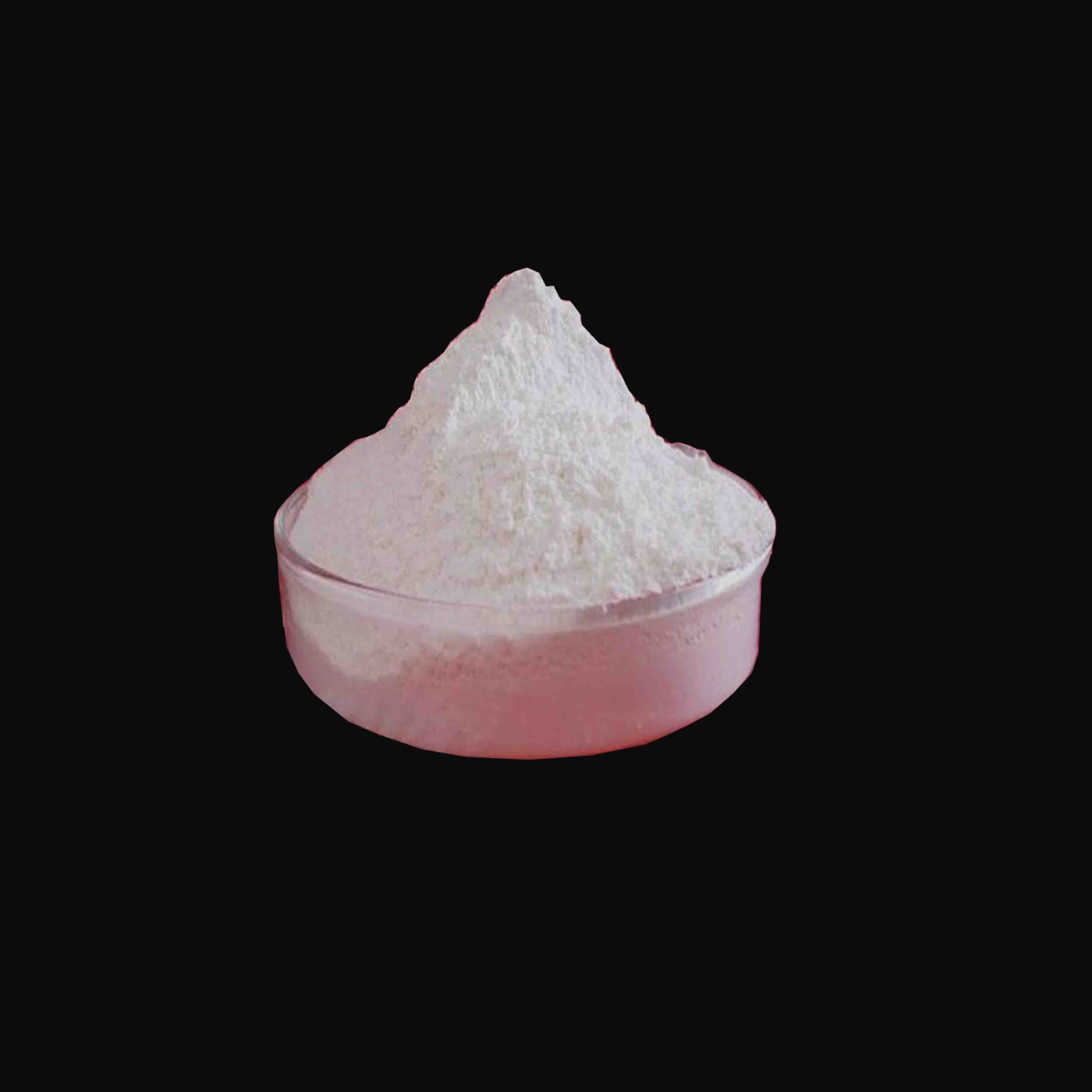

Lithopone, a white pigment composed primarily of zinc sulfide and barium sulfate, is widely used in various applications, including paints, coatings, plastics, and paper. One cannot overlook the importance of safety and proper handling of chemicals in industrial settings, which is where the Material Safety Data Sheet (MSDS) comes into play. This article delves into the significance of lithopone, its MSDS, and its importance in factory settings.

What is Lithopone?

Lithopone was first developed in the 19th century and has established itself as an essential material in the pigment industry due to its excellent opacity and brightness. It is often used as a substitute for more expensive white pigments like titanium dioxide, especially in applications where cost-effectiveness is a priority. Lithopone is known for its high thermal stability and resistance to discoloration when exposed to UV light, making it a preferred choice for outdoor applications.

Importance of the MSDS

The Material Safety Data Sheet (MSDS) provides crucial information regarding the safety, handling, storage, and potential hazards associated with chemicals, including lithopone. The MSDS includes data on chemical properties, health risks, exposure limits, and emergency measures.

For lithopone, the MSDS typically outlines the following key areas

1. Chemical Identification Information about the chemical’s composition and common uses. 2. Hazards Identification Describes potential health effects from exposure, such as respiratory irritations and skin sensitivities. 3. First Aid Measures Outlines crucial steps to take in case of exposure or accidents, ensuring that employees know how to respond effectively. 4. Fire-Fighting Measures Recommendations on materials to use in firefighting, along with potential hazards during a fire.

lithopone msds quotes factory

6. Handling and Storage Guidance for safely dealing with lithopone and storing it properly to prevent degradation or accidents.

Safety Precautions in Factories

In factory settings where lithopone is used, adherence to the guidelines provided in the MSDS is crucial for ensuring worker safety and environmental protection. Workers should be familiar with the MSDS and receive training on the specific risks associated with lithopone, including appropriate personal protective equipment (PPE) such as gloves, masks, and goggles.

Regular training sessions should be conducted to reinforce safety practices, respiratory protection, and proper waste disposal methods. Additionally, employers must ensure that the workplace is equipped with safety equipment like eye wash stations, emergency showers, and spill kits.

Regulatory Compliance

Manufacturers and factories using lithopone are also required to comply with regulations set forth by occupational health and safety administrations, including the Occupational Safety and Health Administration (OSHA) in the United States. Regular inspections and compliance checks can help mitigate risks associated with chemical handling and ensure that companies maintain safe working environments.

Conclusion

Lithopone is more than just a cost-effective pigment; its usage in various industries necessitates a thorough understanding of safety protocols defined in its MSDS. By prioritizing worker safety, adhering to regulations, and fostering a culture of education, factories can effectively manage the challenges associated with using lithopone and similar chemicals. Emphasizing the importance of MSDS in the workplace not only safeguards employees but also enhances operational efficiency in industrial settings.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025