Dec . 22, 2024 13:34 Back to list

rutile vs anatase suppliers

Understanding the Differences Between Rutile and Anatase A Guide for Suppliers

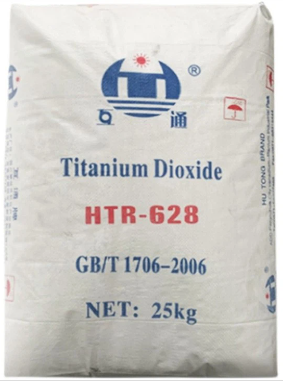

When it comes to titanium dioxide (TiO2), two primary mineral forms dominate the market—rutile and anatase. Both forms have unique properties and applications, making them crucial for various industries, including plastics, paints, coatings, and cosmetics. For suppliers, understanding the differences between rutile and anatase is essential for effective product sourcing and customer satisfaction.

The Basics Composition and Structure

Rutile and anatase are both crystalline forms of titanium dioxide but differ in their crystal structures. Rutile crystallizes in the tetragonal system and has a denser, more stable structure. Its high refractive index and excellent opacity make it the preferred form for many applications, particularly in high-performance coatings and pigments. In contrast, anatase also crystallizes in the tetragonal system but with a less stable structure, which influences its performance characteristics.

From a chemical standpoint, both rutile and anatase consist of the same chemical compound—TiO2—yet their physical properties differ significantly due to their structural variations

.Optical Properties

One of the most significant differences between rutile and anatase lies in their optical properties. Rutile has a higher refractive index (around 2.9) compared to anatase (approximately 2.5). This property makes rutile an excellent choice for applications requiring superior whiteness and brightness. Additionally, rutile is more durable under UV exposure, making it ideal for outdoor applications such as exterior paints and coatings.

Anatase, on the other hand, often finds its place in applications where its photocatalytic properties are advantageous. It is widely used in environmental applications, such as air and water purification, due to its ability to initiate photocatalytic reactions under UV light.

Applications & Market Demand

rutile vs anatase suppliers

Rutile is predominantly used in the production of high-quality white pigments. It is favored in industries that demand durability and resistance to degradation, such as construction materials and automotive coatings. The demand for rutile remains robust, driven by its use in premium applications where performance is critical.

Anatase, while not as widely used as rutile, has found a niche in specialized applications, particularly in sunscreen formulations that capitalize on its photocatalytic properties. It is also used in some types of ceramics and as a catalyst in chemical reactions. The market for anatase is generally smaller, but it is expected to grow as awareness of its environmental applications continues to spread.

Sourcing Considerations for Suppliers

For suppliers, sourcing the right form of titanium dioxide depends on understanding customer needs and market trends. Rutile is often the preferred choice for high-quality applications, which may require suppliers to establish reliable connections with manufacturers who can provide consistent and high-grade materials. This includes looking for suppliers who offer certifications that guarantee product quality and compliance with international standards.

On the other hand, supplying anatase may require a different approach. As an emerging market with growth potential, suppliers should stay informed about technological advancements and new applications of anatase. Building relationships with industries focused on environmental solutions can open up new avenues for sourcing and sales.

Conclusion

In summary, understanding the differences between rutile and anatase is essential for suppliers and purchasers alike. Each form of titanium dioxide serves distinct roles across various industries, affecting decisions on sourcing and product specification. Rutile stands out for its durability and performance in high-quality applications, while anatase presents unique opportunities in environmental and niche markets.

By staying informed about the characteristics, applications, and market trends of these two forms of titanium dioxide, suppliers can better meet the demands of their customers, ensuring long-term success in a competitive landscape. Whether focusing on sourcing high-quality rutile or exploring the potential of anatase, a strategic approach that considers the unique properties of these materials will ultimately lead to greater satisfaction for customers and suppliers alike.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025