Dec . 26, 2024 07:04 Back to list

rutile vs anatase manufacturer

Rutile vs. Anatase A Comparative Overview for Manufacturers

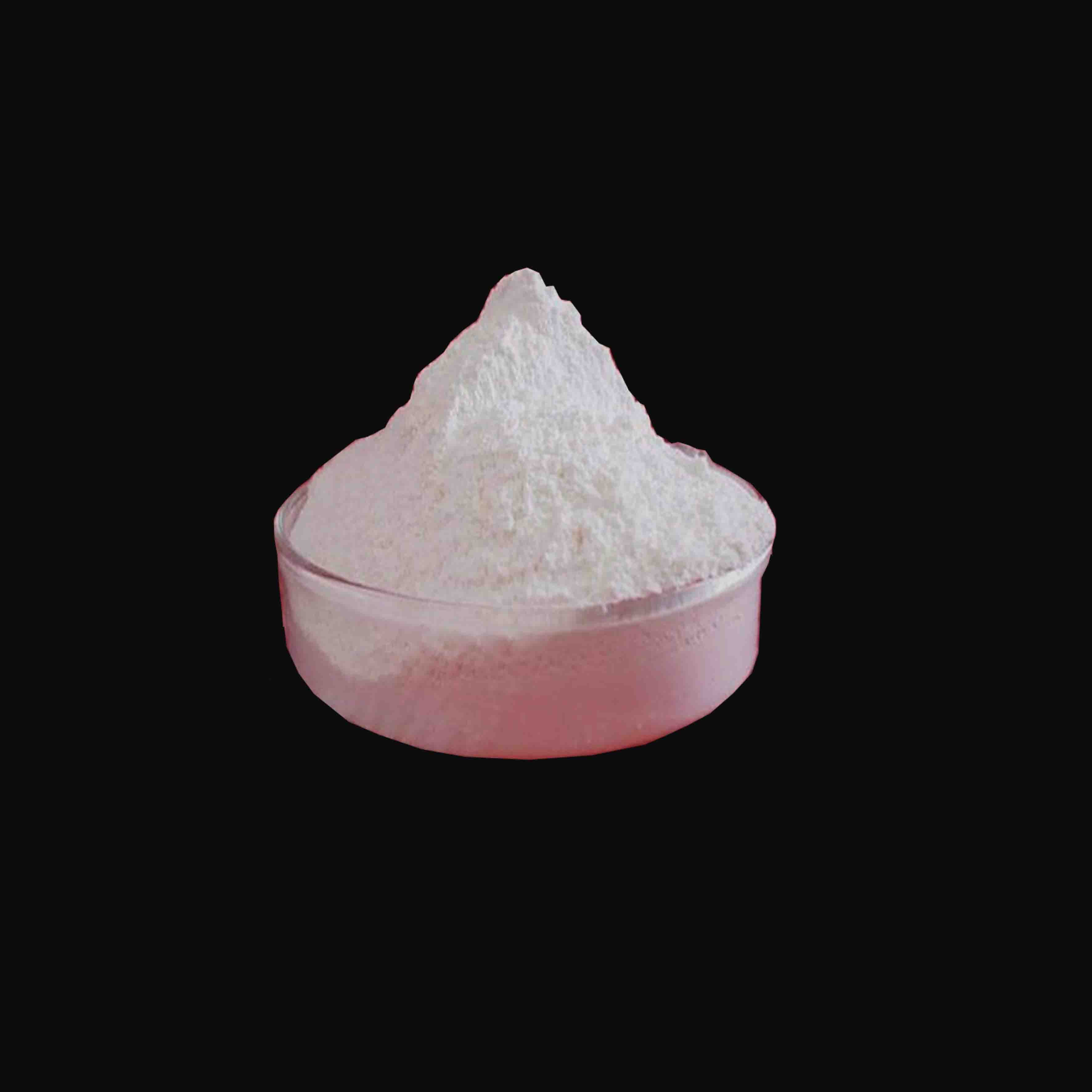

In the world of titanium dioxide (TiO2) production, the two principal crystalline forms, rutile and anatase, play pivotal roles in various industrial applications. While both forms are derived from the same mineral, their distinct properties make them suitable for different uses. Understanding the differences between rutile and anatase is essential for manufacturers looking to optimize their products and processes.

Overview of Titanium Dioxide Crystalline Forms

Titanium dioxide occurs naturally in four main forms brookite, rutile, anatase, and metastable forms. Among these, rutile and anatase are the most commercially significant due to their wide applications in coatings, plastics, papers, and ceramics.

1. Rutile Structure Rutile is the more stable form of titanium dioxide and is characterized by a tetragonal crystal structure. Its high refractive index and excellent light-scattering ability make it an ideal pigment for enhancing the brightness and opacity of products. Rutile also exhibits superior durability and thermal stability, making it suitable for applications in harsh environments.

2. Anatase Structure In contrast, anatase possesses a more complex tetragonal structure and is less stable than rutile. While it has a lower refractive index, its photocatalytic properties are far more pronounced. This makes anatase an excellent choice for applications requiring self-cleaning surfaces, environmental remediation, and photocatalytic reactions.

Key Differences Between Rutile and Anatase

1. Physical Properties Rutile’s higher density and refractive index contribute to its excellent covering power and brightness. Its particles tend to agglomerate, resulting in challenges during dispersion in some applications. Anatase, while having lower density and dispersibility advantages, can provide better tinting strength when used in paint formulations due to its unique surface characteristics.

2. Chemical Stability Rutile is chemically more stable than anatase, making it less reactive and more suitable for outdoor applications such as coatings that require UV resistance. In contrast, anatase, while less durable, exhibits notable photocatalytic properties under UV light, which can be advantageous in indoor air purification products and self-cleaning coatings.

rutile vs anatase manufacturer

3. Applications The choice between rutile and anatase largely depends on the intended application. Rutile is predominantly used in high-performance coatings, plastics, and cosmetics where durability and brightness are priorities. Conversely, anatase is commonly utilized in environments where photocatalytic effects are beneficial, such as in environmental applications, tile, and roofing materials.

Manufacturing Considerations

When it comes to manufacturing, the choice of titanium dioxide form will significantly affect processing methods and product formulation.

- Production Methods The conventional processes for producing rutile and anatase involve the sulfate and chloride routes, each yielding different qualities of TiO2. Manufacturers must choose the method that aligns with their desired product characteristics and market demands.

- Cost Factors Rutile generally commands a higher market value due to its superior properties and demand in high-end applications. However, the lower processing costs associated with anatase can make it a more financially viable option in specific contexts.

- Regulatory and Environmental Aspects As sustainability becomes a focal point in manufacturing, choosing the right form of titanium dioxide also involves considering environmental and regulatory requirements. Anatase’s photocatalytic efficiency can contribute to greener processes, while rutile’s stability may align better with long-term product performance.

Conclusion

In conclusion, the choice between rutile and anatase titanium dioxide is critical for manufacturers seeking to optimize their products for specific applications. Each form possesses unique advantages and disadvantages that cater to different industrial needs. As the market evolves and the demand for specialty products increases, understanding the nuances of rutile vs. anatase will be instrumental for manufacturers aiming to innovate and maintain a competitive edge.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025