Dec . 11, 2024 10:35 Back to list

Supplier of High-Quality Rutile Titanium Dioxide Pigments for Various Applications

The Importance of Rutile Titanium Dioxide Pigment Suppliers in Modern Manufacturing

Rutile titanium dioxide (TiO₂) is a vital pigment widely used across various industries, including paints, coatings, plastics, and even cosmetics. As a supplier of rutile titanium dioxide, one plays a crucial role in ensuring the quality and consistency of this essential material. The significance of this product cannot be overstated, as it enhances the performance and aesthetic qualities of numerous applications, making it a key component in modern manufacturing.

What is Rutile Titanium Dioxide?

Rutile titanium dioxide is one of the three primary crystalline forms of titanium dioxide, the others being anatase and brookite. Rutile is characterized by its high refractive index and strong ultraviolet (UV) light absorption properties, making it an ideal choice for pigmentation purposes. It provides excellent opacity, brightness, and durability, which are essential for products that are exposed to harsh environmental conditions.

The process of producing rutile titanium dioxide involves the extraction of titanium ore, followed by complex refining methods such as the sulfate and chloride processes. Each method yields different grades of TiO₂, with rutile-grade typically being preferred for its superior performance characteristics.

The Role of Suppliers

Rutile titanium dioxide pigment suppliers play a critical role in the supply chain, connecting manufacturers with the high-quality raw materials they need for their products

. The responsibilities of a TiO₂ supplier extend beyond just selling the pigment; they must ensure that the product meets industry standards and specifications.1. Quality Assurance Suppliers must adhere to stringent quality control measures to guarantee that their rutile titanium dioxide meets performance criteria. This involves regular testing in laboratories to assess properties such as purity, particle size distribution, and refractive index. Ensuring consistent quality helps manufacturers maintain the desired performance in their end products.

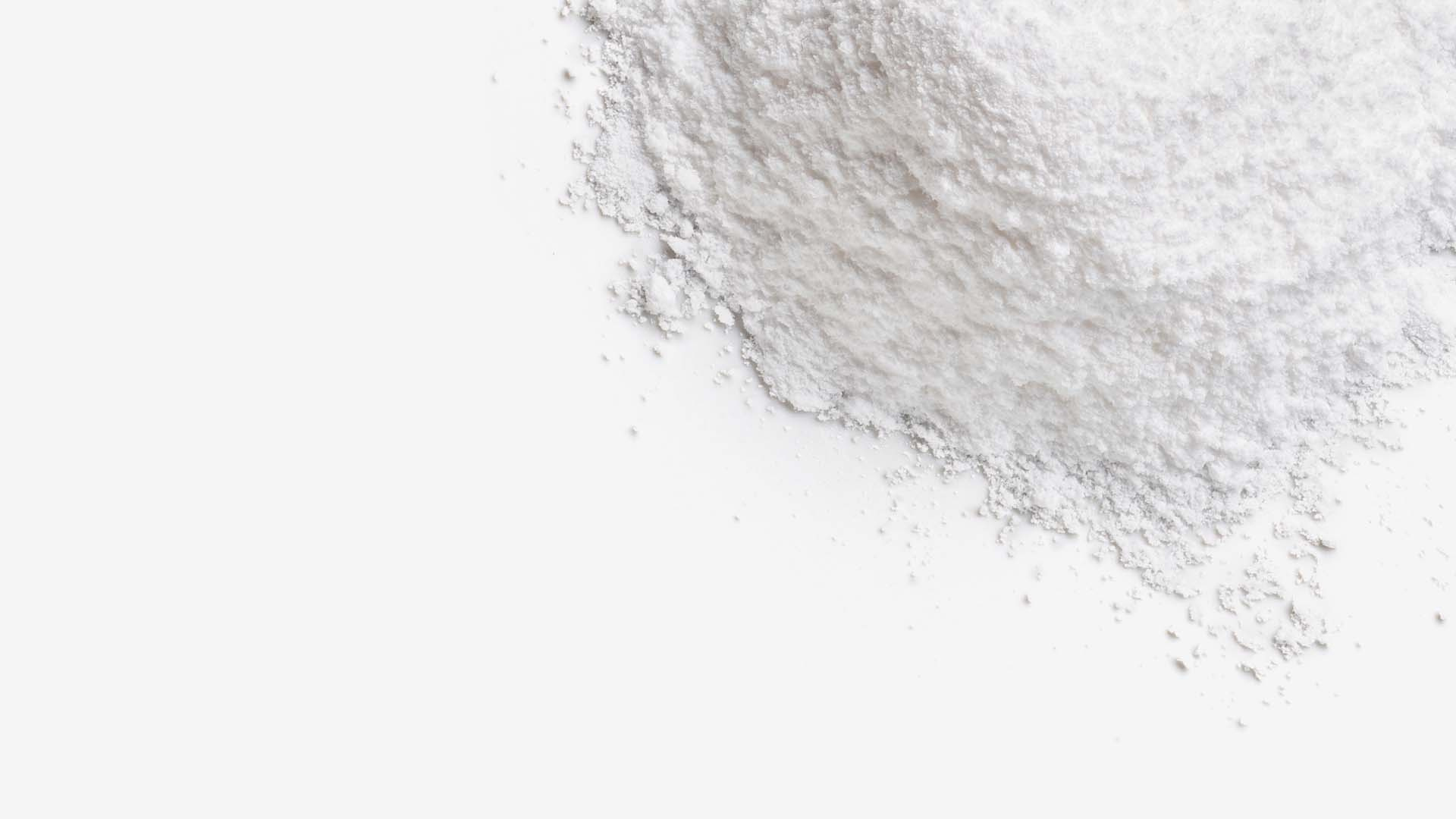

rutile titanium dioxide pigment supplier

2. Customization Different applications require different formulations of titanium dioxide. Therefore, suppliers often offer customized solutions to meet specific customer requirements. This tailored approach allows manufacturers to achieve better results in their applications, whether they are developing a high-performance paint or a durable plastic product.

3. Technical Support Knowledgeable suppliers provide valuable technical support to their clients. This includes assistance with product selection, application advice, and troubleshooting during the production process. By offering such support, suppliers can help manufacturers optimize their processes and improve product quality.

4. Sustainability Practices As environmental concerns become increasingly important, many suppliers are striving to implement sustainable practices in their operations. This includes reducing waste, minimizing energy consumption, and developing eco-friendly production methods. Suppliers that prioritize sustainability can not only meet regulatory requirements but also cater to the growing consumer demand for greener products.

Current Market Trends

The global market for rutile titanium dioxide is experiencing significant growth, driven by expanding applications in industries like construction, automotive, and consumer goods. The increasing demand for high-quality, environmentally friendly products is shaping market dynamics, leading to more research and development in TiO₂ formulations.

Moreover, geopolitical factors and trade policies can also impact the supply chain of rutile titanium dioxide. Suppliers must navigate these complexities to ensure a steady supply of high-quality pigment to their customers, often building strategic partnerships with manufacturers to mitigate risks.

Conclusion

Rutile titanium dioxide pigment suppliers are essential players within the manufacturing ecosystem. They not only provide a critical raw material but also ensure that manufacturers can meet the demands of quality, performance, and sustainability. As industries continue to evolve and prioritize innovative solutions, the role of TiO₂ suppliers will remain pivotal in driving progress and enhancing the functionalities of a wide array of products. With ongoing advancements in production technology and a commitment to sustainability, the future of rutile titanium dioxide looks promising, paving the way for exciting developments in multiple sectors.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025