Nov . 16, 2024 08:20 Back to list

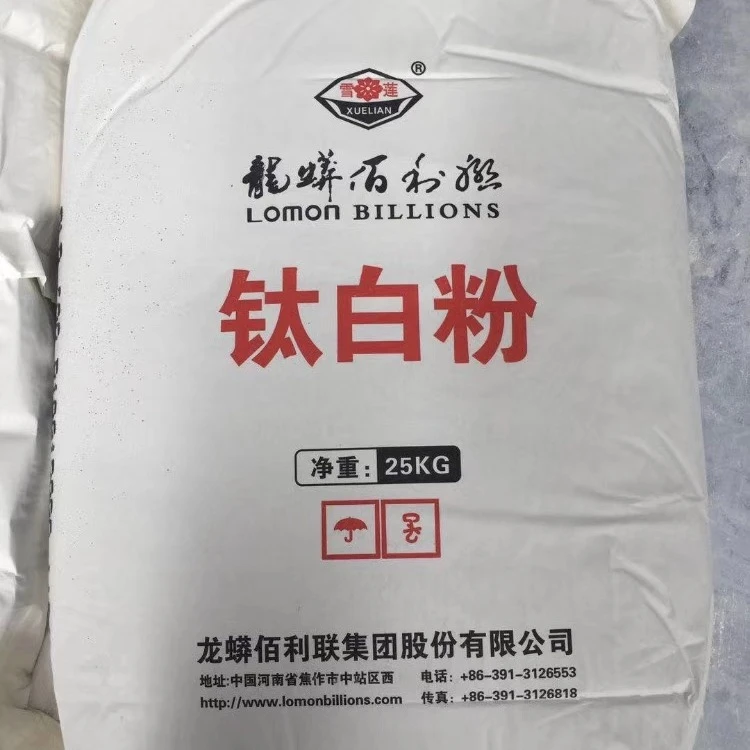

rutile titanium dioxide industry grade for paint factories

The Role of Rutile Titanium Dioxide in the Paint Industry

Rutile titanium dioxide, often referred to as TiO2, is one of the most important white pigments used in the paint industry due to its outstanding properties. With its high refractive index, excellent durability, and non-toxic nature, rutile titanium dioxide plays a pivotal role in enhancing the quality and performance of paints and coatings.

Properties and Benefits of Rutile Titanium Dioxide

Rutile titanium dioxide is characterized by its bright white color and high opacity, which makes it an ideal pigment in various applications. The primary attributes that make rutile TiO2 highly sought-after in paint manufacturing include

1. High Opacity and Brightness Rutile titanium dioxide has a superior hiding power compared to alternative white pigments such as zinc oxide or lead white. This high opacity means that less pigment is required to achieve the desired whiteness in paints, thus conserving resources and reducing production costs.

2. UV Resistance Paints that incorporate rutile TiO2 exhibit excellent resistance to ultraviolet (UV) radiation. This property helps to prevent degradation and fading, ensuring that coated surfaces remain vibrant and intact over time, even when exposed to harsh environmental conditions.

3. Chemical Stability Rutile titanium dioxide is chemically stable and does not react with the solvents or other compounds present in paint formulations. This stability contributes to the shelf life and durability of the final product and ensures consistent performance during application.

4. Non-Toxicity As an inorganic compound, rutile titanium dioxide is non-toxic and safe for use in both indoor and outdoor applications. This characteristic makes it an ideal choice for paints used in residential areas, schools, and facilities where safety and health are paramount concerns.

Applications in the Paint Industry

rutile titanium dioxide industry grade for paint factories

Rutile titanium dioxide is primarily used in the formulation of architectural coatings, industrial paints, and decorative paints. Its versatility allows it to be used across a range of substrates, including wood, metal, and plastic. Here are some common applications

- Architectural Paints In residential and commercial buildings, rutile TiO2 is utilized to produce high-quality exterior and interior paints. These paints are not only aesthetically pleasing but also durable and resistant to environmental stressors.

- Industrial Coatings The automotive industry frequently uses rutile titanium dioxide in the production of finishes and protective coatings for vehicles. Its UV resistance and durability are critical in protecting vehicles from corrosion and wear.

- Specialty Coatings Rutile TiO2 is also used in specialty coatings, including anti-corrosive paints, marine coatings, and powder coatings. These applications require pigments that can withstand rigorous conditions, and rutile titanium dioxide meets these demands effectively.

Market Dynamics and Future Trends

The demand for rutile titanium dioxide in the paint industry continues to grow, driven by increasing urbanization, infrastructure development, and the need for high-quality coatings. Environmental regulations are also pushing manufacturers to adopt sustainable practices, leading to innovations in TiO2 production methods, including more efficient extraction processes and recycling techniques.

As the industry evolves, the development of enhanced formulations that incorporate rutile titanium dioxide alongside other materials is likely to gain traction. These advancements may lead to paints with improved performance characteristics, such as better adhesion, self-cleaning properties, and even energy efficiency.

Conclusion

Rutile titanium dioxide remains a cornerstone of the paint industry, owing to its exceptional properties and wide-ranging applications. As manufacturers strive for quality and sustainability in their products, the importance of this versatile pigment is only set to increase. The continued development of advanced formulations will ensure that rutile TiO2 remains at the forefront of innovation in paint and coating technologies, meeting the demands of both consumers and the environment.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025