Dec . 03, 2024 16:23 Back to list

Rutile TiO2 Production and Supply for Industrial Applications

The Growing Importance of Rutile TiO2 in Various Industries

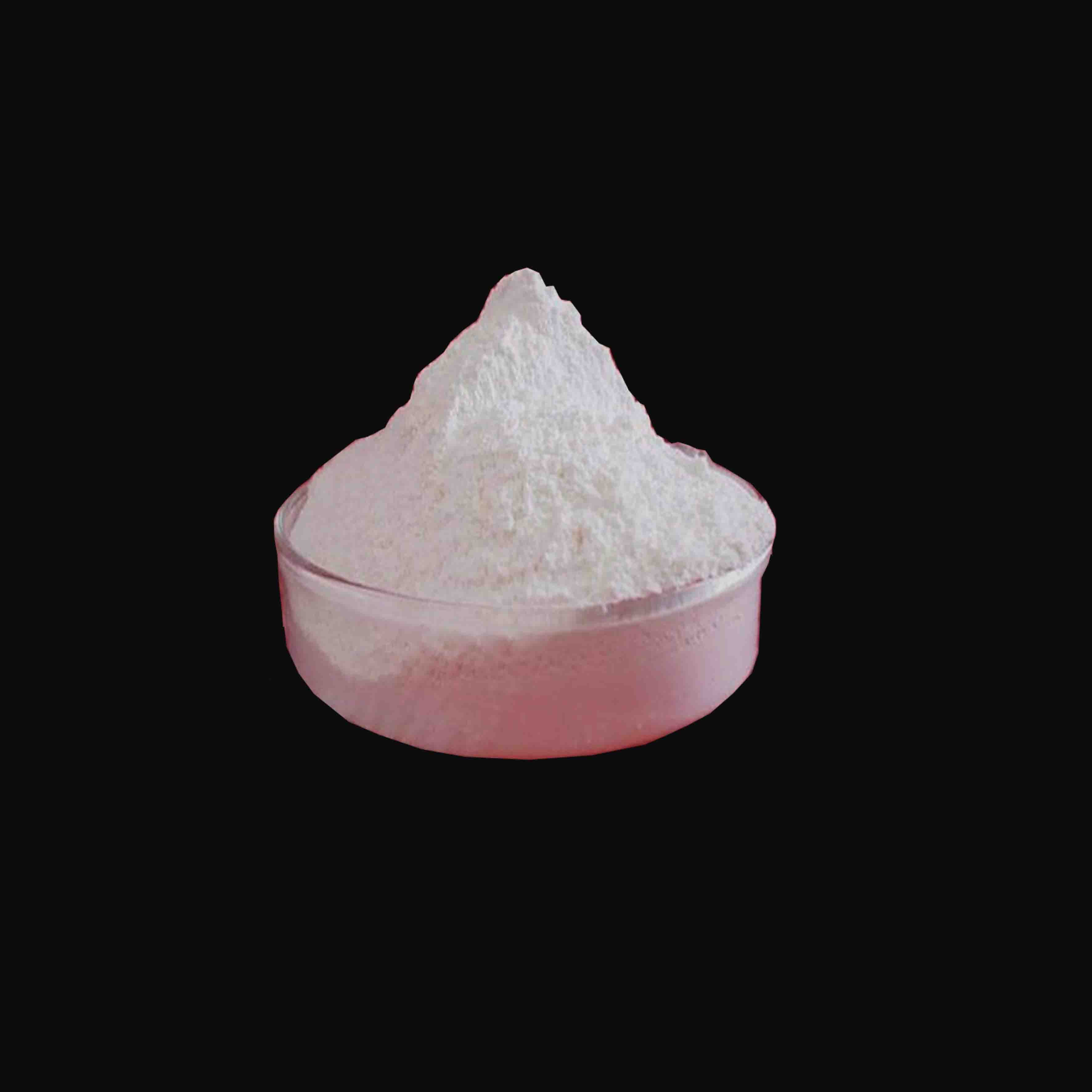

Rutile titanium dioxide (TiO2) has emerged as one of the most significant compounds in various industrial applications, thanks to its excellent properties such as high refractive index, durability, and non-toxicity. As industries pivot towards sustainable and efficient materials, the demand for rutile TiO2 is experiencing a remarkable surge. This article delves into the properties, production processes, and applications of rutile TiO2, shedding light on why it is a preferred choice for manufacturers across multiple sectors.

Understanding Rutile TiO2

Rutile is one of the three primary natural mineral forms of titanium dioxide, the others being anatase and brookite. What sets rutile apart is its superior optical and physical characteristics. It has a high refractive index (approximately 2.7), exceptional UV light absorption, and remarkable durability and corrosion resistance. These properties make rutile TiO2 an ideal pigment and functional material in various applications.

Production Process

The manufacture of rutile TiO2 can be divided into two main processes the sulfate process and the chloride process.

1. Sulfate Process In this traditional method, ilmenite ore is treated with sulfuric acid. The resulting titanium dioxide is then precipitated and calcined to produce rutile. This process is well-established and efficiently produces high-purity TiO2; however, it generates a considerable amount of waste.

2. Chloride Process A more modern and environmentally friendly approach, the chloride process involves converting titanium ore into titanium tetrachloride (TiCl4) through chlorination. This method is generally more efficient and produces very high-purity rutile TiO2 with fewer byproducts. As companies focus on sustainability, the chloride process has gained prominence among manufacturers, allowed by advancements in technology.

Applications of Rutile TiO2

Rutile TiO2 finds extensive applications across numerous sectors, largely due to its unique properties

rutile tio2 manufacturer

1. Paints and Coatings The paint industry is one of the largest consumers of TiO2. Rutile TiO2 is used as a pigment because it provides excellent coverage and durability while enhancing the brightness and whiteness of paints. Its UV protection capabilities make it ideal for outdoor applications.

2. Plastics In the plastics industry, rutile TiO2 is employed as a pigment and filler to improve opacity and reduce thermal degradation. Its durability and resistance to heat make it suitable for various plastic products ranging from containers to automotive parts.

3. Cosmetics Rutile TiO2 is widely used in cosmetic formulations, particularly in sunscreens and skin products. Its ability to reflect UV rays makes it a vital ingredient for protecting the skin from harmful sun exposure.

4. Paper The paper industry utilizes rutile TiO2 to enhance brightness and opacity in products. The addition of TiO2 improves the visual quality of paper, making it more appealing to consumers.

5. Pharmaceuticals In the pharmaceutical sector, TiO2 serves as a pigment for tablet coatings, contributing to the aesthetic appeal and aiding in the identification of medications.

The Future of Rutile TiO2

As the global focus shifts towards sustainability, manufacturers are increasingly seeking eco-friendly materials. The rutile TiO2 market is predicted to witness substantial growth, driven by the rising demand for high-performance pigments and coatings. Continuous innovations in production techniques, such as the development of more efficient processes and the recovery of waste materials, are expected to enhance the attractiveness of rutile TiO2 in various applications.

Furthermore, regulatory pressures regarding environmental protection may further drive the adoption of rutile TiO2 over other alternatives. With its non-toxic properties and high performance, rutile TiO2 stands poised to meet the demands of an evolving market that values sustainability and efficiency.

Conclusion

In conclusion, rutile titanium dioxide is an essential material that plays a crucial role in a myriad of industries. As manufacturers continue to recognize its unique properties and applications, the demand for high-quality rutile TiO2 is likely to expand. This trend not only highlights the material's versatility but also underscores its importance in fostering innovations across sectors, making it an indispensable part of modern manufacturing practices.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025