Nov . 03, 2024 15:29 Back to list

rutile grade titanium dioxide r1930 chloride process dupont ink manufacturer

Rutile Grade Titanium Dioxide R1930 The DuPont Chloride Process and Its Impact on Ink Manufacturing

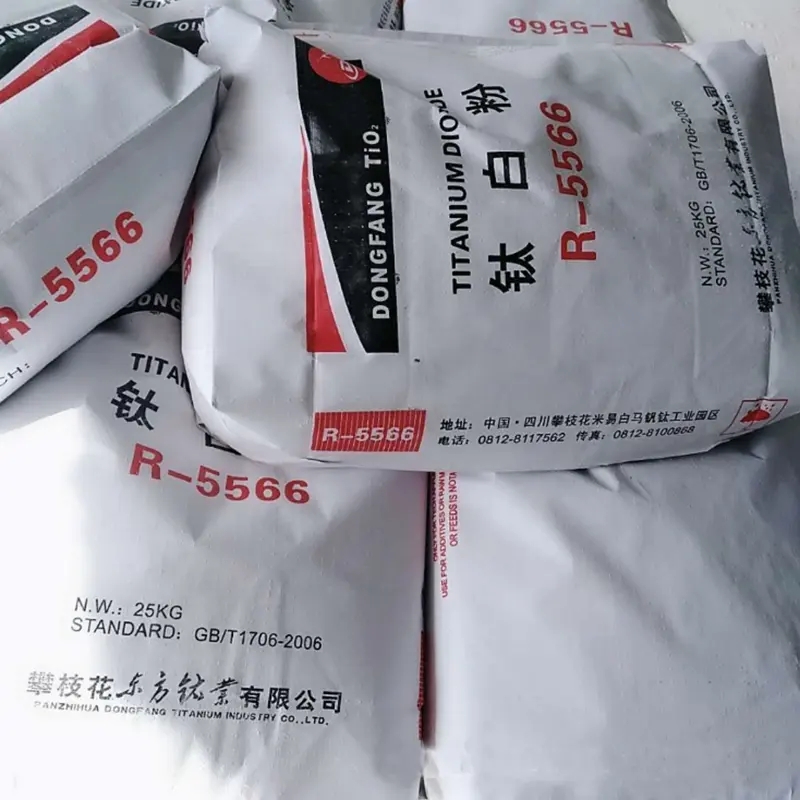

Titanium dioxide (TiO2) is an extensively used white pigment across various industries, particularly in coatings, plastics, and ink manufacturing. Among the multiple production methods for TiO2, the chloride process, notably implemented by DuPont, has gained significant attention for its efficiency and high-quality output. One of the prominent grades produced by this method is the rutile grade R1930, known for its superior properties and applications.

The chloride process, developed by DuPont in the mid-20th century, involves the conversion of titanium-bearing ores, such as ilmenite or rutile, into titanium tetrachloride (TiCl4) through chlorination. This TiCl4 is then oxidized to produce titanium dioxide. The advantages of the chloride process include a lower environmental impact, reduced production costs, and a higher purity of the final product compared to the sulfate process. The end result is a rutile grade titanium dioxide known for its excellent optical characteristics, brightness, and durability.

R1930, specifically, has garnered attention in the ink manufacturing sector due to its outstanding performance attributes. It demonstrates high hiding power, which is crucial for achieving opacity in various ink formulations. Additionally, R1930 exhibits excellent dispersion properties, ensuring uniform pigment distribution within the ink. This quality is essential for maintaining consistent color and finish during the printing process, be it in commercial or artistic applications.

rutile grade titanium dioxide r1930 chloride process dupont ink manufacturer

Another noteworthy aspect of R1930 is its resistance to ultraviolet (UV) degradation

. In ink formulations, especially those exposed to sunlight, this characteristic is vital for ensuring longevity and preserving color vibrancy over time. As manufacturers increasingly focus on creating high-performance inks to meet the demands of modern printing technologies, R1930 stands out as a reliable choice.Additionally, the chloride process contributes to the eco-friendly profile of R1930. As industries move towards sustainable practices, the minimal waste generation and lower emissions associated with this production method align with these goals. By opting for pigments like R1930, ink manufacturers can enhance their sustainability credentials while delivering high-quality products.

In conclusion, rutile grade titanium dioxide R1930 produced through the DuPont chloride process represents the epitome of innovation in ink manufacturing. With its remarkable hiding power, dispersion properties, and UV resistance, R1930 meets the ever-evolving demands of the ink industry. As sustainability becomes a pivotal concern for manufacturers, the environmentally friendly chloride process further reinforces R1930's position as a preferred choice, heralding a new era of efficient and responsible ink production. As technology advances, the potential for R1930 and similar products to reshape the landscape of ink manufacturing remains vast, promising even better performance and sustainability for future applications.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025