Oct . 30, 2024 18:26 Back to list

rutile anatase factory

Understanding the Dynamics of Rutile and Anatase in the Manufacturing Sector

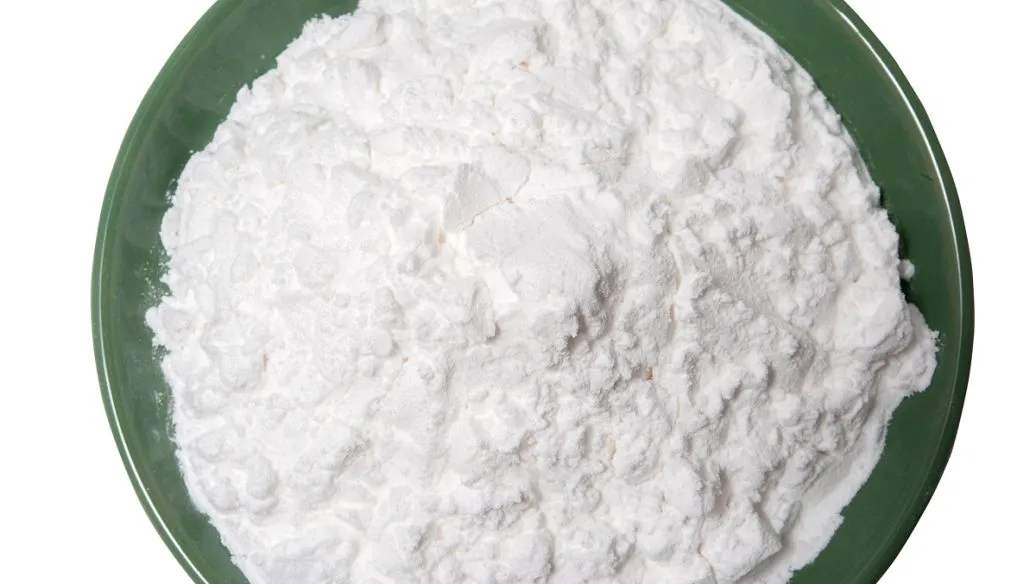

In the sphere of titanium dioxide production, rutile and anatase are two vital forms of TiO2 that serve different purposes across various industries. Each variant possesses unique properties and advantages, making them suitable for specific applications. Understanding the significance of these two polymorphs, along with the manufacturing processes involved, is essential for stakeholders in industries ranging from paints and coatings to plastics and pharmaceuticals.

Understanding the Dynamics of Rutile and Anatase in the Manufacturing Sector

Conversely, anatase, which is less stable than rutile, is prized for its photocatalytic properties. This makes it an essential component in environmental applications, such as air and water purification, where it can facilitate chemical reactions that degrade pollutants. Anatase also finds its place in the production of solar cells, where its semiconducting properties can enhance energy conversion efficiency. With the growing emphasis on sustainability, the demand for anatase in eco-friendly technologies is steadily rising, prompting manufacturers to innovate and optimize production processes.

rutile anatase factory

The manufacturing process for both rutile and anatase typically involves the sulfate and chloride processes. The sulfate process, though more traditional, is associated with higher energy costs and environmental impacts. In contrast, the chloride process, which produces predominantly rutile, is more efficient and environmentally friendly, leading to its increasing adoption in modern factories.

The trade-off between rutile and anatase also manifests in pricing dynamics. Rutile generally commands a higher price due to its superior qualities and broader application range, whereas anatase is more competitively priced, appealing to cost-sensitive sectors. This dynamic necessitates strategic planning and market analysis for manufacturers who must balance quality, performance, and cost-effectiveness.

In conclusion, both rutile and anatase play significant roles in various industries, each contributing distinct advantages that cater to specific market needs. The ongoing pursuit of innovation in their manufacturing processes not only enhances their functional properties but also aligns with the global movement toward sustainability. Understanding these dynamics is crucial for manufacturers aiming to leverage the full potential of titanium dioxide in an increasingly competitive marketplace.

-

What is Barium Sulfate Board? Uses, Benefits & Industry Insights

NewsNov.25,2025

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025