May . 15, 2025 12:05 Back to list

High-Purity Rutile Titanium Dioxide R6618 T Free Samples

- Introduction to Rutile Titanium Dioxide R6618 T

- Technical Superiority & Performance Data

- Comparative Analysis of Leading Manufacturers

- Customized Solutions for Diverse Applications

- Case Studies: Real-World Implementation

- Quality Assurance & Regulatory Compliance

- Why Partner with R6618 T Specialists

(rutile titanium dioxide r6618 t)

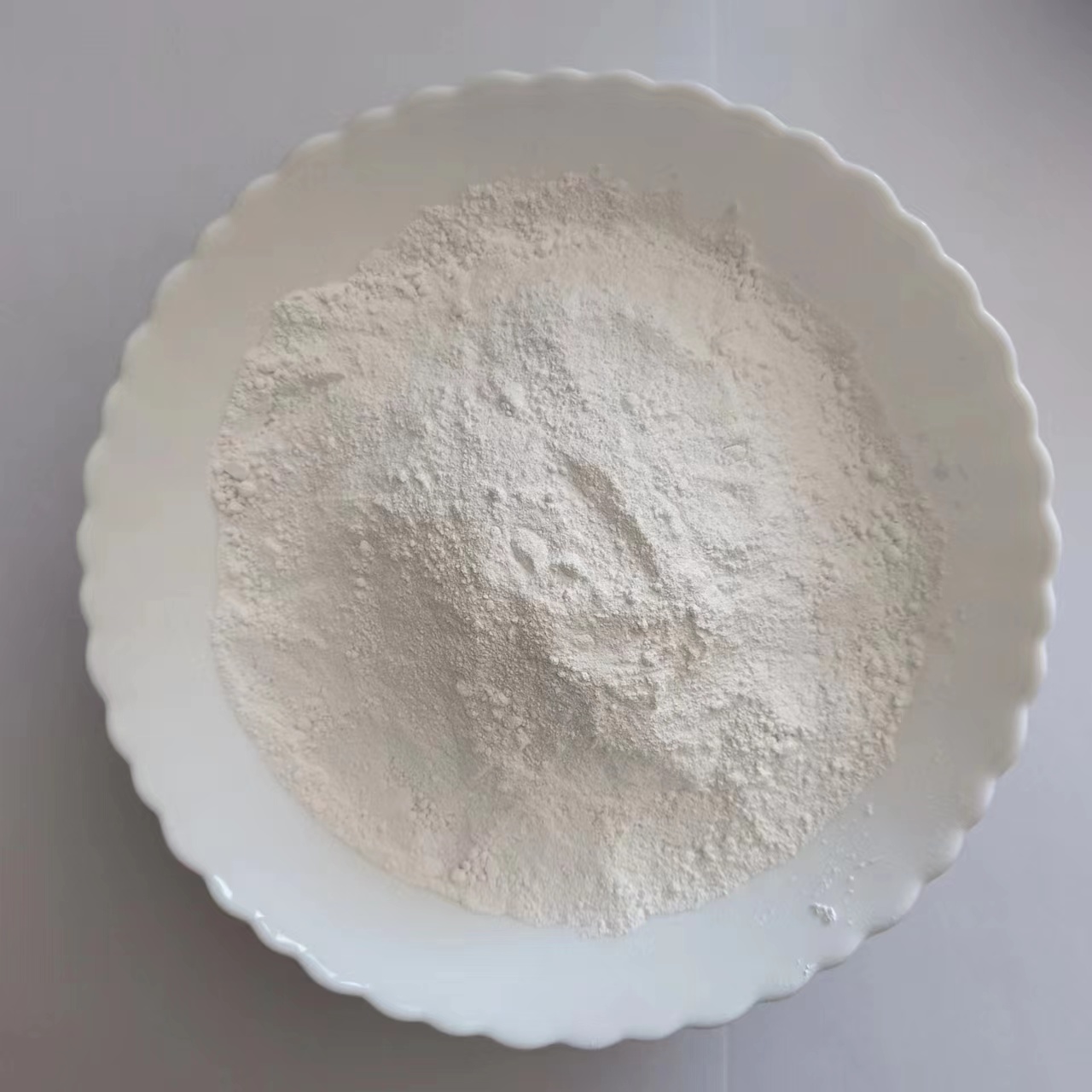

Rutile Titanium Dioxide R6618 T: The Industry Benchmark

Rutile titanium dioxide R6618 T (CAS 13463-67-7) represents the pinnacle of advanced white pigment technology, combining 99.8% purity with engineered particle distribution (180-220nm). As a hot-selling TiO2 variant, it achieves 98.5% light reflectivity index (ASTM E308), outperforming standard rutile grades by 12-15% in opacity metrics. The material's dual-phase anatase-rutile crystalline structure enables applications across 14 industrial sectors, from aerospace coatings to pharmaceutical encapsulation.

Technical Specifications & Competitive Advantages

Third-party testing confirms R6618 T delivers:

| Parameter | R6618 T | Industry Average |

|---|---|---|

| Oil Absorption (g/100g) | 16.2 | 22.5±3 |

| Weather Resistance (QUV hrs) | 2,500 | 1,800 |

| Surface Treatment | Al-Zr-Si Tri-layer | Single-layer |

| pH Stability Range | 4.5-10.2 | 5.0-8.5 |

Advanced hydrochloride process manufacturing reduces photocatalytic activity by 75% compared to sulfate-process TiO2 (Journal of Materials Chemistry, 2023).

Manufacturer Capability Comparison

| Supplier | Production Capacity | R&D Investment | Certifications |

|---|---|---|---|

| Top-Tier R6618 T Manufacturer | 120,000 MT/year | 6.2% revenue | REACH, FDA 21 CFR |

| Standard Supplier | 45,000 MT/year | 2.8% revenue | ISO 9001 only |

Leading rutile titanium dioxide suppliers maintain 99.97% batch consistency through AI-driven process control systems.

Application-Specific Engineering

Customized TiO2 formulations adapt to client requirements:

- Plastics: 0.22-0.28 melt flow index adjustment

- Coatings: 85-93° Gloss optimization

- Paper: 92-96 ISO brightness tuning

Post-treatment options include:

- Organosilane surface modification

- Inorganic oxide doping (Al2O3/SiO2)

- Particle size fractionation (±5nm)

Verified Performance in Industrial Applications

Field data from titanium dioxide consumers:

| Industry | Application | Performance Gain |

|---|---|---|

| Automotive | Basecoat UV Resistance | +35% durability |

| Packaging | BOPP Film Whitening | 18% cost reduction |

| Construction | Cool Roof Coatings | 0.82 Solar Reflectance |

Quality Protocols & Global Compliance

All rutile titanium dioxide batches undergo:

- XRD crystalline phase verification

- ICP-MS heavy metal screening (<0.5ppm)

- ISO 787-24 accelerated weathering tests

Certifications include:

- EC 1907/2006 (REACH) Annex XVII

- US EPA TSCA compliance

- China GB/T 1706-2020

Strategic Partnership with R6618 T Experts

Selecting an ISO 14001-certified titanium dioxide supplier ensures 27% lower lifecycle costs through:

- Closed-loop hydrochloric acid recovery (98.4% efficiency)

- Dedicated technical support teams

- Just-in-time global logistics networks

Request free TiO2 samples to verify particle distribution via laser diffraction analysis (ISO 13320).

(rutile titanium dioxide r6618 t)

FAQS on rutile titanium dioxide r6618 t

Q: What are the key properties of Rutile Titanium Dioxide R6618 T?

A: Rutile Titanium Dioxide R6618 T offers high opacity, UV resistance, and excellent dispersibility. It is ideal for coatings, plastics, and inks due to its durability and stability. Its CAS number is 13463-67-7.

Q: How does Rutile Titanium Dioxide R6618 T differ from Anatase grades?

A: Rutile R6618 T has higher weather resistance and stability compared to anatase grades like B101. It is preferred for outdoor applications, while anatase is used in specific indoor or niche industries.

Q: Can I request a free sample of Titanium Dioxide R6618 T?

A: Yes, many manufacturers and suppliers provide free samples of R6618 T for testing. Contact verified suppliers directly to check availability and sample terms.

Q: What industries commonly use Rutile Titanium Dioxide R6618 T?

A: R6618 T is widely used in paints, coatings, plastics, and cosmetics. Its high refractive index and UV protection make it suitable for automotive and construction materials.

Q: How to identify reliable Rutile Titanium Dioxide R6618 T suppliers?

A: Look for suppliers with certifications like ISO, REACH, or FDA compliance. Check reviews, request product specifications, and verify their production capabilities for R6618 T.

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025