Sep . 06, 2024 12:15 Back to list

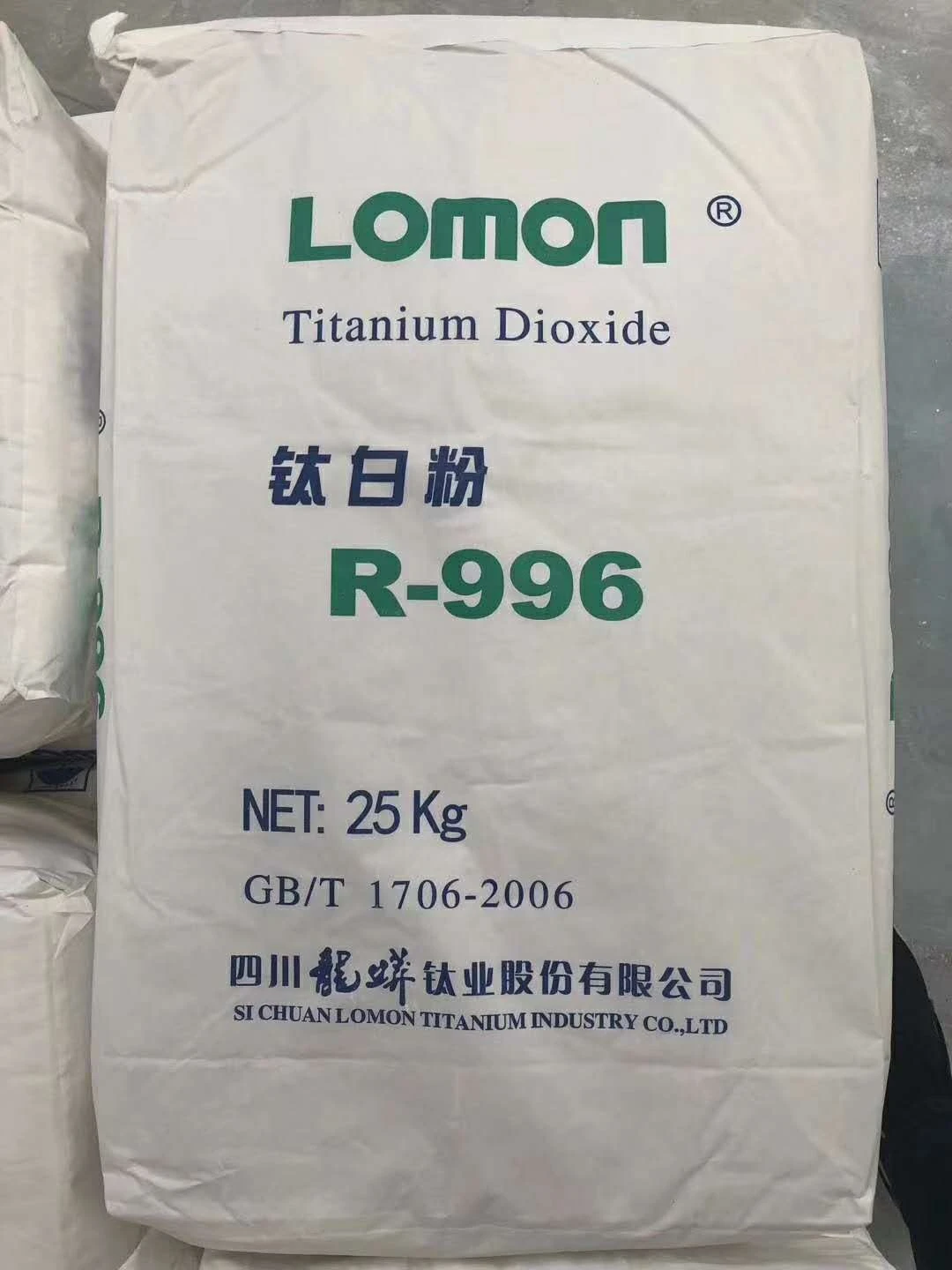

High-Quality Rutile and Anatase Titanium Dioxide Manufacturer

The Production Dynamics of Rutile and Anatase Titanium Dioxide

Titanium dioxide (TiO2) is one of the most widely utilized materials in various industries, primarily owing to its exceptional whiteness and UV resistance. It exists in two primary crystalline forms rutile and anatase. Each form possesses distinctive properties that make it suitable for specific applications, leading to a burgeoning global market for TiO2 production.

Rutile titanium dioxide, characterized by its high refractive index and excellent opacity, is predominantly used in applications requiring superior pigment quality. It is the preferred choice for the paint, coatings, and plastics industries, contributing to its dominance in the market. The production of rutile TiO2 typically involves the sulfate process or the chloride process. The sulfate process uses sulfuric acid to convert titanium ores into TiO2, which is then purified through a series of chemical reactions. In contrast, the chloride process begins with the chlorination of titanium ores, producing a more pure and high-quality TiO2.

On the other hand, anatase titanium dioxide is favored for its photocatalytic properties, making it an ideal choice for applications in self-cleaning surfaces, air purification, and water treatment. The production of anatase often utilizes the same methods as rutile, but variations in processing conditions lead to the formation of this particular crystal structure. Anatase is typically less stable than rutile at high temperatures, which can limit its applications in certain high-performance environments.

rutile and anatase titanium dioxide factory

The demand for titanium dioxide is influenced by various factors including the growth of the construction industry, advancements in technology, and increasing concerns for environmental sustainability. Companies are continuously innovating to enhance the efficiency of production processes, reduce energy consumption, and minimize waste. The shift towards more eco-friendly practices is significant, as the industry faces scrutiny regarding its environmental impact and resource use.

As the market evolves, the landscape for rutile and anatase TiO2 production is becoming increasingly competitive. Major players in the industry are investing in research and development to explore alternative sources, such as recycling and the use of lesser-known titanium minerals. Furthermore, globalization has opened opportunities for new markets, particularly in developing regions where demand for quality products is on the rise.

In conclusion, the production of rutile and anatase titanium dioxide is a dynamic sector that plays a crucial role in various industries. With ongoing advancements, a focus on sustainability, and an eye towards market demands, the future of TiO2 production looks promising, positioning it as a vital component in the global manufacturing landscape.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025