Sep . 29, 2024 01:51 Back to list

Exploring R996 Grade TiO2 Production Processes and Factory Innovations

The Role of R996 TiO2 Factories in Modern Industries

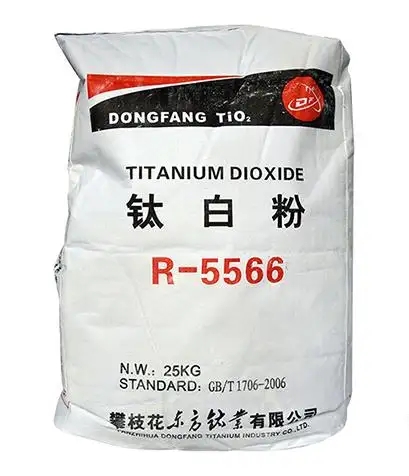

Titanium dioxide (TiO2) is a widely used compound known for its brightness and high refractive index. It is predominantly used as a pigment in products ranging from paints and coatings to plastics and cosmetics. Among the various grades produced, R996 TiO2 stands out as a high-performance variant renowned for its exceptional properties. R996 TiO2 factories play a crucial role in supplying this vital material, which has significant implications for numerous industries.

The production of R996 TiO2 typically involves the sulfate or chloride.process, each providing distinct advantages. The sulfate process is characterized by the use of sulfuric acid to extract titanium dioxide from ilmenite ore, resulting in a product primarily featuring rutile crystalline structure. This type is known for its excellent opacity and UV resistance, making it ideal for applications in outdoor paints where longevity and durability are paramount.

The Role of R996 TiO2 Factories in Modern Industries

The R996 TiO2 factories are equipped with advanced technology and stringent quality control measures to ensure the consistency and purity of the product. This involves the careful monitoring of the raw materials, production processes, and final output. As environmental concerns rise and regulations become stricter, these factories are also adapting to ensure sustainable production practices. Techniques such as recycling waste materials and employing cleaner production technologies are being integrated to minimize the ecological footprint of R996 TiO2 manufacturing.

r996 tio2 factories

In recent years, the demand for R996 TiO2 has surged, driven by growth in the construction and automotive sectors. The construction industry, in particular, relies heavily on high-quality pigments for paints and coatings that provide aesthetic appeal as well as protection against environmental factors. Meanwhile, the automotive industry uses R996 TiO2 for its exceptional optical properties and durability in exterior paints, contributing to the overall longevity and performance of vehicles.

Moreover, the plastics industry has recognized the value of R996 TiO2 in enhancing material properties. By incorporating this compound, manufacturers can improve the opacity, brightness, and UV resistance of plastics, making products more appealing and functional. This versatility extends to various end-use applications, including packaging, consumer goods, and even electronics.

With the ever-increasing push towards sustainability, R996 TiO2 factories are also exploring innovative applications in renewable energy, particularly in photovoltaic cells. The reflective properties of titanium dioxide can enhance the efficiency of solar panels, making this a promising area for growth in the coming years.

In conclusion, R996 TiO2 factories are integral to modern industry, providing a key material that enhances the quality and performance of a multitude of products. As market demands evolve and sustainability becomes a priority, these factories are poised to adapt and innovate, ensuring that R996 TiO2 continues to play a vital role in the development of new technologies and products. With their commitment to quality and sustainability, R996 TiO2 factories will not only meet current industry needs but also contribute to a more sustainable future.

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025