Nov . 22, 2024 17:17 Back to list

r 2196 titanium dioxide factories

Titanium Dioxide Factories An Overview of Production and Environmental Considerations

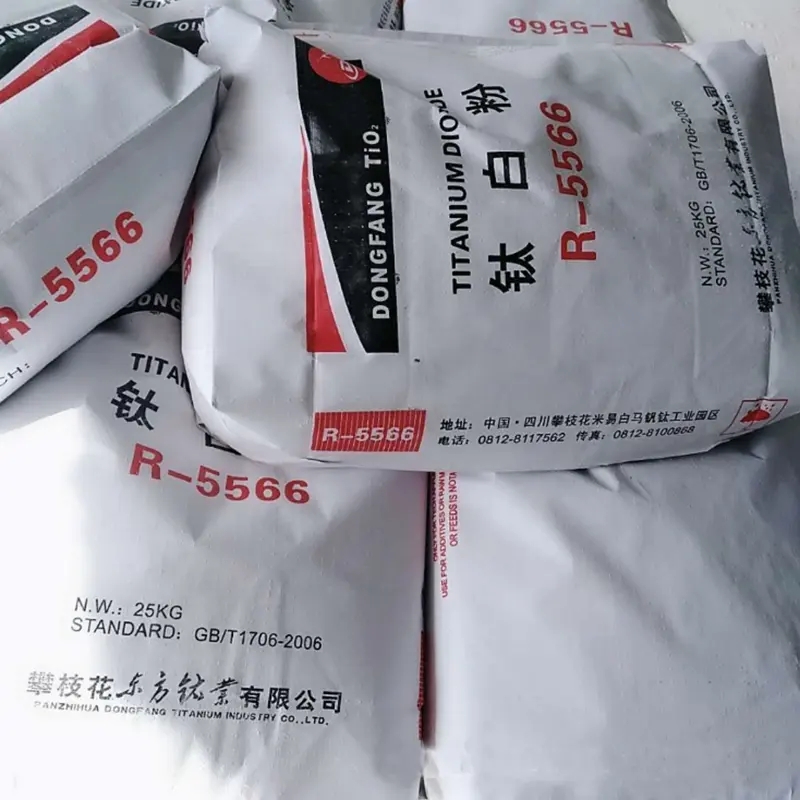

Titanium dioxide (TiO2) is a versatile white pigment widely used in various industries, from paints and coatings to plastics, cosmetics, and food products. Its unique properties, including high refractive index, opacity, and UV resistance, make it an essential component in numerous applications. The global demand for titanium dioxide has spurred the establishment and expansion of titanium dioxide factories, which are crucial in meeting market requirements. However, this growth comes with significant environmental considerations that need to be addressed.

The Production Process

Titanium dioxide can be produced through two primary processes the sulfate process and the chloride process.

1. Sulfate Process This older method involves the reaction of ilmenite (a natural ore containing iron and titanium) with sulfuric acid. The resultant titanium sulfate is then hydrolyzed to yield titanium dioxide. The sulfate process is less expensive and suitable for low-grade ores, but it generates large amounts of waste and can cause significant pollution.

2. Chloride Process In contrast, the chloride process is a modern and more environmentally friendly method that involves the conversion of titanium-containing ores into titanium tetrachloride (TiCl4) using chlorine gas. The TiCl4 is then oxidized to produce titanium dioxide. This method is typically more efficient and results in higher purity titanium dioxide, but it requires more energy and advanced technology.

Both processes have their advantages and disadvantages, and the choice between them often depends on the specific requirements of the production facility, market demands, and environmental regulations.

Environmental Considerations

The production of titanium dioxide, particularly through the sulfate process, raises several environmental concerns. The process generates waste materials, including iron sulfate and other by-products, which can be challenging to dispose of. Additionally, these factories often use large quantities of water and can be sources of air and water pollution if not properly managed.

r 2196 titanium dioxide factories

Moreover, the mining of titanium ores can lead to habitat destruction, soil erosion, and other ecological impacts

. As a result, it is crucial for titanium dioxide manufacturers to adopt sustainable practices. This includes implementing pollution control technologies, recycling waste products, and minimizing resource use.Regulatory Framework

Governments and international organizations have recognized the potential environmental impacts of titanium dioxide production. Regulations surrounding air quality, waste disposal, and water use are increasingly stringent. Manufacturers must comply with these regulations to minimize their environmental footprint.

In many regions, a shift towards more sustainable production practices is being encouraged through incentives and subsidies for companies that adopt cleaner technologies. Additionally, the development and commercialization of eco-friendly alternatives to traditional titanium dioxide are on the rise, which could potentially reduce the environmental burden associated with its production.

Future Trends

The future of titanium dioxide production is likely to be shaped by technological advancements and changing market demands. There is a growing emphasis on sustainability, which is pushing manufacturers to innovate new processes that reduce waste and energy consumption. For instance, research is ongoing into the use of biomass and other renewable resources in titanium dioxide production.

Furthermore, as consumers become more environmentally conscious, demand for sustainably produced products will likely increase. This trend could drive the adoption of greener technologies in titanium dioxide factories, ultimately benefiting both the industry and the environment.

Conclusion

Titanium dioxide factories play a crucial role in meeting the global demand for this essential pigment. While the production processes have evolved significantly, they still present environmental challenges that must be addressed. Balancing industrial growth with environmental stewardship will be essential as the industry moves forward. By investing in sustainable practices and innovative technologies, titanium dioxide producers can ensure a more responsible and environmentally friendly future for the manufacturing of this vital material.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025