Dec . 14, 2024 21:55 Back to list

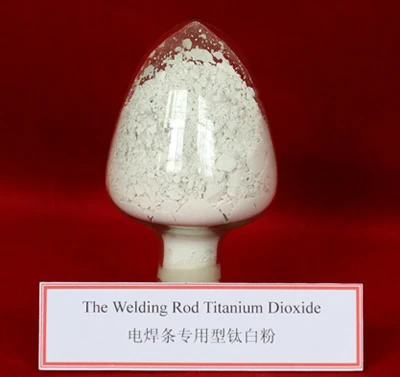

Top Manufacturer of High-Quality Pure Titanium Dioxide for Various Applications

The Role of Pure Titanium Dioxide Manufacturers in the Modern Market

In today's industrial landscape, the production and application of pure titanium dioxide (TiO2) have garnered significant attention across numerous sectors, including cosmetics, food, pharmaceuticals, and especially paints and coatings. It serves as a crucial ingredient due to its excellent opacity, brightness, and UV resistance. As the demand for high-quality titanium dioxide continues to rise, the role of pure titanium dioxide manufacturers becomes increasingly vital.

Understanding Titanium Dioxide

Titanium dioxide is a white pigment known for its brightness and high refractive index. It is primarily produced through two processes the sulfate process and the chloride process. The sulfate process uses sulfuric acid to extract TiO2 from titanium ore, while the chloride process involves reacting titanium tetrachloride with oxygen to produce titanium dioxide. Of these, the chloride process is favored for its ability to produce higher purity titanium dioxide, essential for advanced applications.

The Manufacturing Process

Pure titanium dioxide manufacturers employ sophisticated technologies to ensure the quality and purity of their products. The key steps in the manufacturing process include

1. Raw Material Selection The process begins with the careful selection of raw materials, mainly ilmenite or rutile, which are the primary sources of titanium.

2. Processing and Purification Once the raw materials are acquired, they undergo rigorous processing. In the chloride process, titanium ores are converted into titanium tetrachloride. The conversion process must be meticulously controlled to ensure minimal contamination.

3. Crystallization and Calcination The titanium tetrachloride produced is then oxidized to form titanium dioxide through crystallization. This is followed by calcination, where the material is heated at high temperatures to enhance its properties and ensure it meets industry standards.

4. Post-processing Treatments To achieve specific characteristics such as hydrophobicity or enhanced dispersion, further treatments and coatings are applied to the titanium dioxide. These finishing processes are crucial for applications in coatings, plastics, and personal care products.

Market Applications

pure titanium dioxide manufacturer

The versatility of pure titanium dioxide makes it indispensable in various industries

- Paints and Coatings It is predominantly used in paints due to its excellent opacity and weather resistance, providing durability and aesthetic qualities to exterior and interior surfaces.

- Cosmetics In cosmetics, titanium dioxide serves both as a pigment and a sunblock agent, effectively reflecting UV rays and enhancing the appearance of products.

- Food Industry Food-grade titanium dioxide is used as a whitening agent in products like confections, dairy, and sauces, ensuring an appealing presentation while adhering to strict safety regulations.

- Pharmaceuticals In the pharmaceutical sector, titanium dioxide is used in the formulation of tablets and capsules, providing a protective coating that ensures the integrity of the product.

Quality Assurance and Environmental Considerations

Leading manufacturers of pure titanium dioxide maintain strict quality assurance protocols to ensure that their products meet international regulations and standards. Certifications such as ISO 9001 and ISO 14001 are commonly sought, illustrating commitment to quality management and environmental protection.

Moreover, there is an increasing focus on sustainability within the titanium dioxide industry. Manufacturers are adopting greener approaches, including recycling processes, reducing waste, and adopting eco-friendly methods of production to minimize their ecological footprint.

Conclusion

The role of pure titanium dioxide manufacturers is pivotal in supporting various industries that rely on this versatile pigment. As the market for high-quality titanium dioxide continues to expand, the commitment to innovation, quality assurance, and environmental sustainability will define the future of this essential product. Companies that effectively balance these elements are likely to thrive, contributing to advancements in technology and improved consumer products that enhance everyday life.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025