Oct . 03, 2024 04:20 Back to list

Assessing the Impact of Titanium Dioxide Production on Precipitation Levels in Manufacturing Facilities

Understanding the Precipitation of Titanium Dioxide in Industrial Processes

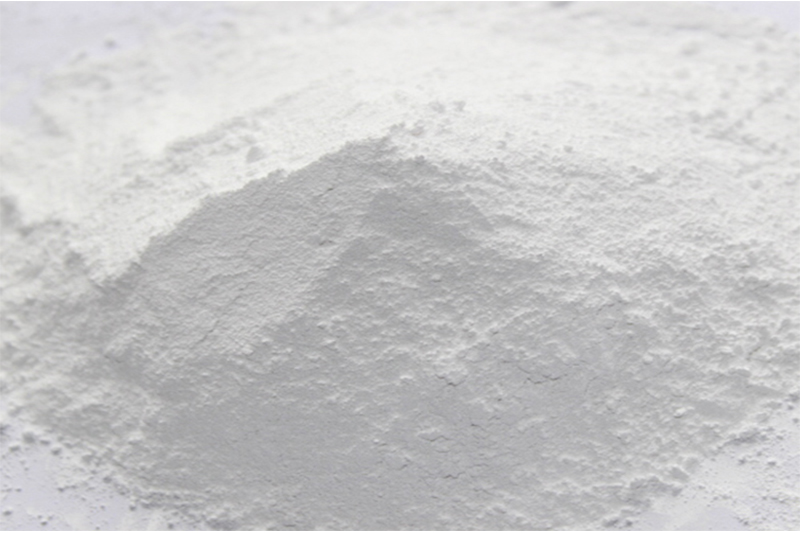

Titanium dioxide (TiO2) is a highly valuable compound widely used across various industries, particularly in pigments, paints, and coatings due to its excellent UV resistance, brightness, and non-toxicity. The production of TiO2 often involves a complex chemical process, one of the critical steps being the precipitation phase, which plays a significant role in determining the quality and efficiency of the end product.

Precipitation is a fundamental process in the synthesis of titanium dioxide, particularly in the sulfate and chloride routes used for TiO2 production. Each route employs a unique set of chemical reactions that lead to the formation of TiO2 from titanium-bearing ores. In the sulfate process, titanium ores are treated with sulfuric acid, leading to the formation of titanium sulfate. This solution is then mixed with water and ammonium sulfate, causing TiO2 to precipitate out. The titanium dioxide formed can then be filtered, washed, and calcined to achieve the desired properties.

On the other hand, the chloride route begins with the chlorination of titanium ores, producing titanium tetrachloride (TiCl4). This vapor is then oxidized to produce TiO2 through a controlled precipitation process. The choice between these two methods largely depends on the desired characteristics of the final product, cost considerations, and environmental impacts.

The efficiency of the precipitation process is influenced by various factors, including pH levels, temperature, and the concentration of reactants. For instance, controlling the pH is crucial because it affects the solubility of titanium species. A higher pH typically favors the formation of TiO2 nanoparticles, while a lower pH may lead to different complexes that could affect the final morphology of the TiO2 crystals.

precipitation of titanium dioxide equation factories

Furthermore, temperature plays a pivotal role in the kinetics of precipitation. Higher temperatures can enhance the reaction rates, leading to faster precipitation, but may also result in non-uniform particle sizes. This is essential for industries seeking specific TiO2 attributes, such as particle size and surface area, which significantly impact the performance of TiO2 in applications ranging from paint to sunscreen formulations.

Environmental considerations have led many factories to adopt more sustainable methods in the TiO2 production process. Innovations in precipitation techniques seek to minimize waste and reduce carbon footprints. Some manufacturers are exploring the use of biodegradable solvents and less harmful chemicals, addressing regulatory pressures to enhance sustainability without compromising product quality.

Quality control during the precipitation phase is imperative for producing high-purity titanium dioxide. Contaminants can adversely affect TiO2's performance in applications; thus, factories employ multiple analytical techniques to ensure that the precipitated product meets the industry standards. These techniques may include X-ray diffraction (XRD) for phase identification and scanning electron microscopy (SEM) for morphology assessment.

In conclusion, the precipitation of titanium dioxide is a critical step in its industrial production. By carefully controlling the factors involved in this phase and adopting sustainable practices, manufacturers can produce high-quality TiO2 that meets the diverse needs of various industries. As the demand for environmentally friendly products increases, continuous advancements in precipitation techniques will be integral to the future of titanium dioxide production.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025